Preparation method of three-dimensional carbon network loaded cobalt ferrite nanoparticle composite wave absorber

A network loading, nanoparticle technology, applied in the field of wave absorbing materials, can solve the problems of complex preparation process, limited development and application, low yield, etc., and achieve the effect of simple preparation process and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

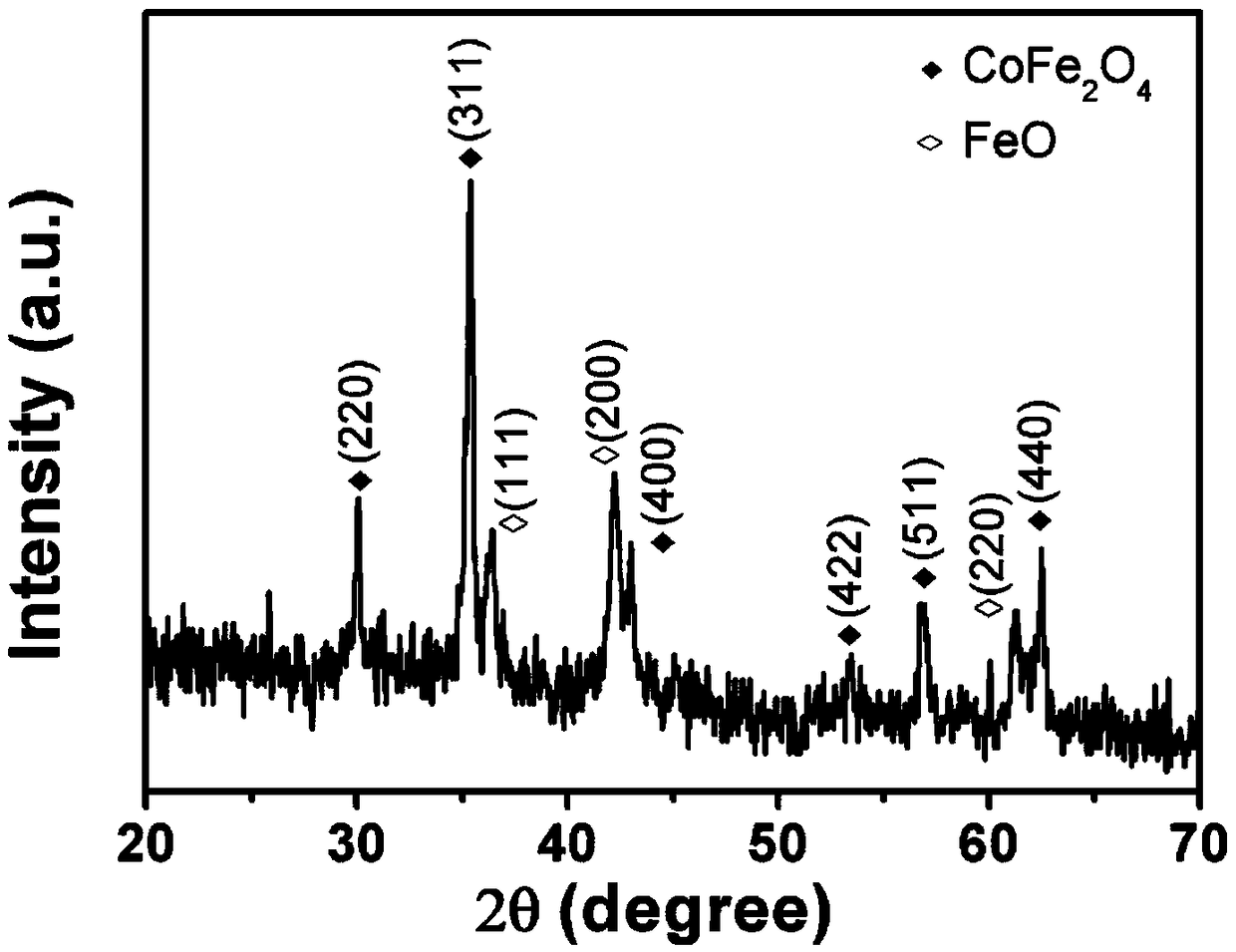

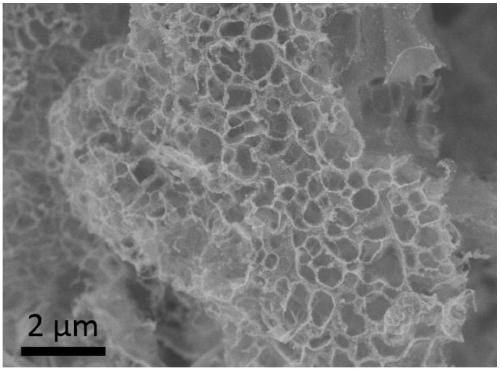

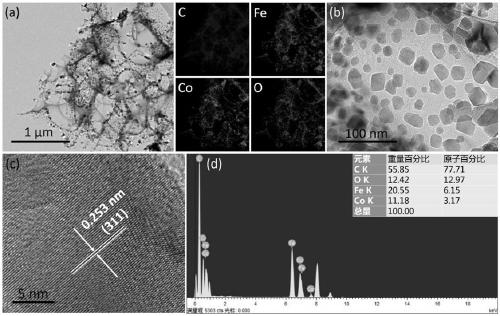

[0021] Weigh 0.647g cobalt nitrate hexahydrate, 1.796g ferric nitrate nonahydrate, 2.667g anhydrous glucose, 39g sodium chloride, dissolve the mixture in 130ml deionized water and magnetically stir for 4 hours to obtain a uniform mixed solution. The resulting solution was poured into two petri dishes with a diameter of 18 cm, and then placed in a refrigerator and frozen at -20° C. for 24 h. The frozen two trays of solution were put into a freeze dryer, and vacuum-dried at -50°C for 24 hours to obtain a precursor. Grind the precursor into powder, take 15g and put it in the ark, put the ark into the constant temperature zone of the tube furnace, pass through 400ml / min Ar for 15min to exhaust the air, then use 80ml / min Ar as the protective atmosphere, and set the temperature at 10℃ / min The heating rate was increased to 630°C, and the carbonization of glucose and the decomposition of cobalt nitrate and ferric nitrate were carried out at the heat preservation for 2 hours. After the...

Embodiment 2

[0025] Weigh 0.647g cobalt nitrate hexahydrate, 1.796g ferric nitrate nonahydrate, 2.667g anhydrous glucose, 39g sodium chloride, dissolve the mixture in 130ml deionized water and magnetically stir for 4 hours to obtain a uniform mixed solution. The resulting solution was poured into two petri dishes with a diameter of 18 cm, and then placed in a refrigerator and frozen at -20° C. for 24 h. The frozen two trays of solution were put into a freeze dryer, and vacuum-dried at -50°C for 24 hours to obtain a precursor. Grind the precursor into powder, take 15g and put it in the ark, put the ark into the constant temperature zone of the tube furnace, pass through 400ml / min Ar for 15min to exhaust the air, then use 80ml / min Ar as the protective atmosphere, and set the temperature at 10℃ / min The heating rate was increased to 600°C, and the carbonization of glucose and the decomposition of cobalt nitrate and ferric nitrate were carried out at the heat preservation for 2 hours. After the...

Embodiment 3

[0027]Weigh 0.647g cobalt nitrate hexahydrate, 1.796g ferric nitrate nonahydrate, 2.667g anhydrous glucose, 39g sodium chloride, dissolve the mixture in 130ml deionized water and magnetically stir for 4 hours to obtain a uniform mixed solution. The resulting solution was poured into two petri dishes with a diameter of 18 cm, and then placed in a refrigerator and frozen at -20° C. for 24 h. Put the frozen two trays of solutions into a freeze dryer, and dry them under vacuum at -50°C for 24 hours to obtain the precursor. Grind the precursor into powder, take 15g and put it in the ark, put the ark into the constant temperature zone of the tube furnace, pass through 400ml / min Ar for 15min to exhaust the air, then use 80ml / min Ar as the protective atmosphere, and set the temperature at 10℃ / min The heating rate was increased to 620 ° C, and the carbonization of glucose and the decomposition of cobalt nitrate and ferric nitrate were carried out at the heat preservation for 2 hours. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective absorption bandwidth | aaaaa | aaaaa |

| Effective absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com