Cleaning product containing styrene-acrylic acid-maleic anhydride copolymer and application thereof

An acid anhydride copolymer, maleic anhydride technology, applied in detergent compounding agent, detergent composition, organic detergent composition, etc., can solve the problem of no obvious effect on the surface of polyester fiber fabric, and achieve outstanding anti-ash deposition effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

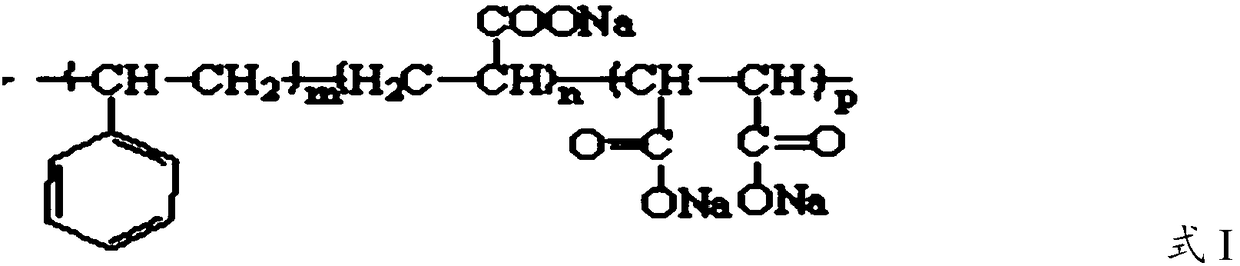

[0024] When the source of the styrene-acrylic acid-maleic anhydride copolymer is self-prepared, the preparation method preferably includes the following steps:

[0025] (1) Acrylic acid, maleic anhydride, sodium lauryl sulfate and water are mixed to obtain a mixed solution;

[0026] (2) mixing said mixed solution, styrene and initiator to carry out polymerization reaction;

[0027] (3) After the reaction is finished, the reaction solution is cooled to normal temperature, and the pH is adjusted with lye to obtain a styrene-acrylic acid-maleic anhydride copolymer solution;

[0028] In the present invention, the molar ratio of the acrylic acid, maleic anhydride and styrene is preferably (0.1-1):(0.1-1):(0.1-1).

[0029] In the present invention, the amount of sodium lauryl sulfate is preferably 0.5% to 3% of the total mass of acrylic acid, maleic anhydride and styrene, more preferably 1% of the total mass of acrylic acid, maleic anhydride and styrene . In the present invention...

Embodiment 1

[0038] (1) In the reactor, add acrylic acid and maleic anhydride in a molar ratio of 1:1, then add sodium lauryl sulfate and water with a total monomer mass of 0.6%, stir and heat to 70°C;

[0039] (2) in the reactor, drip simultaneously the initiator of the styrene of the same molar number as acrylic acid and monomer gross mass 2%, and the dropping time is 2h;

[0040] (3) After reacting for 4 hours, cool down to normal temperature, adjust the pH to 6 with lye, and obtain the styrene-acrylic acid-maleic anhydride copolymer.

[0041] The weight average molecular weight of the copolymer was measured by gel chromatography, and the result showed that the weight average molecular weight of the styrene-acrylic acid-maleic anhydride copolymer was 12530.

Embodiment 2

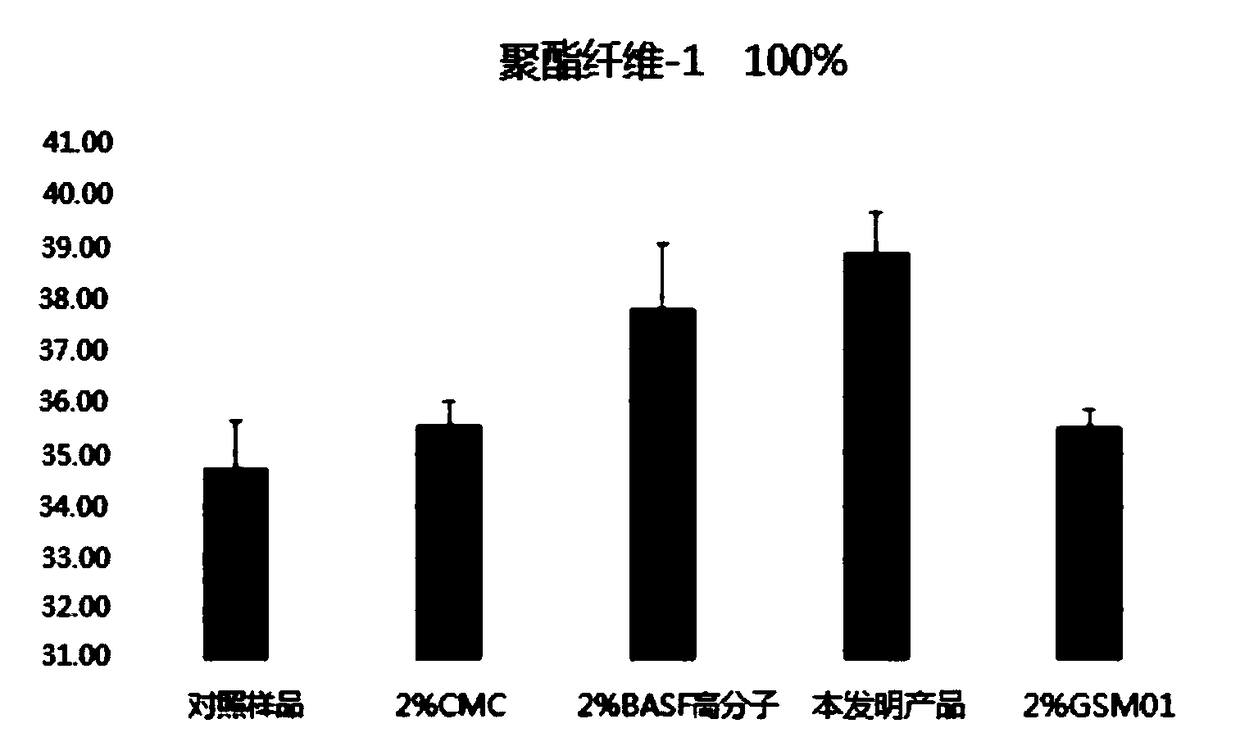

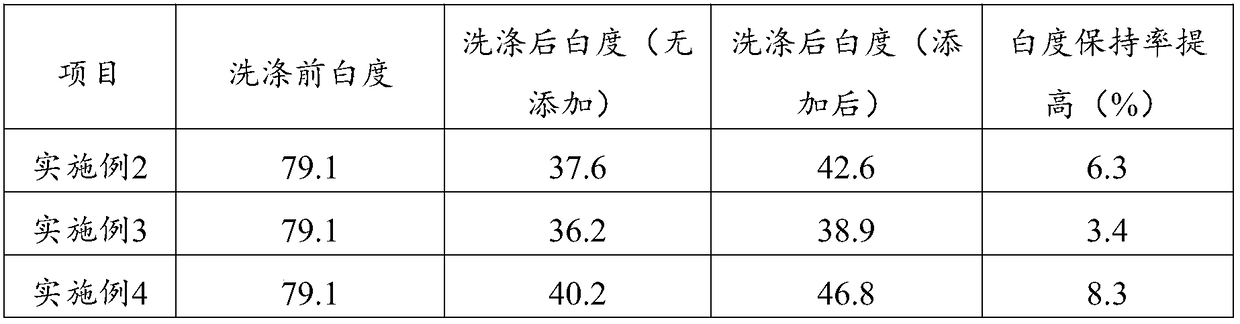

[0043] The styrene-acrylic acid-maleic anhydride copolymer that 0.1g embodiment 1 obtains is added to the detergent of 99.9g (this detergent contains the tensio-active agent of 16% weight portion, and wherein LAS accounts for 3%, and AEO accounts for 8%, AES5%, the remaining functional additives include 1% citric acid, 1% carboxymethyl cellulose, 0.2% HEDP, 0.5% NaCl, the pH value of the detergent is 7.5), stir evenly to obtain styrene-acrylic acid-horse Washing products with 0.1% toric anhydride copolymer content. Carry out washing and whiteness test on polyester fiber stained cloth, the test method is in accordance with GB / T 13174-2008 "Determination of Detergency and Cycle Washing Performance of Detergents for Clothing", and carbon black is used instead of the national standard JB-01 dirty liquid. The obtained results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com