A high-speed transistor and a manufacturing method thereof

A manufacturing method and transistor technology, applied in the field of electronics, can solve problems such as small band gap and poor stability of high-speed transistors, and achieve the effects of increasing breakdown voltage, reducing requirements, and improving frequency and power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

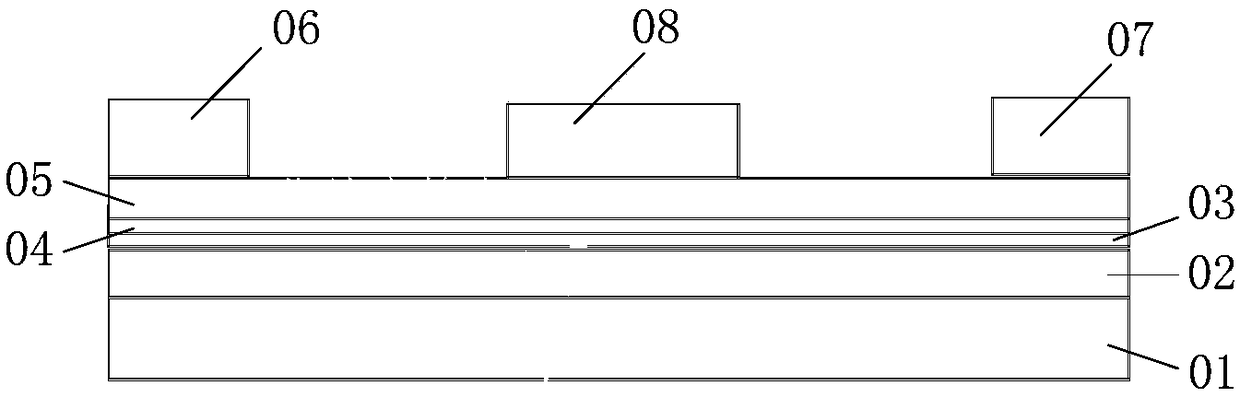

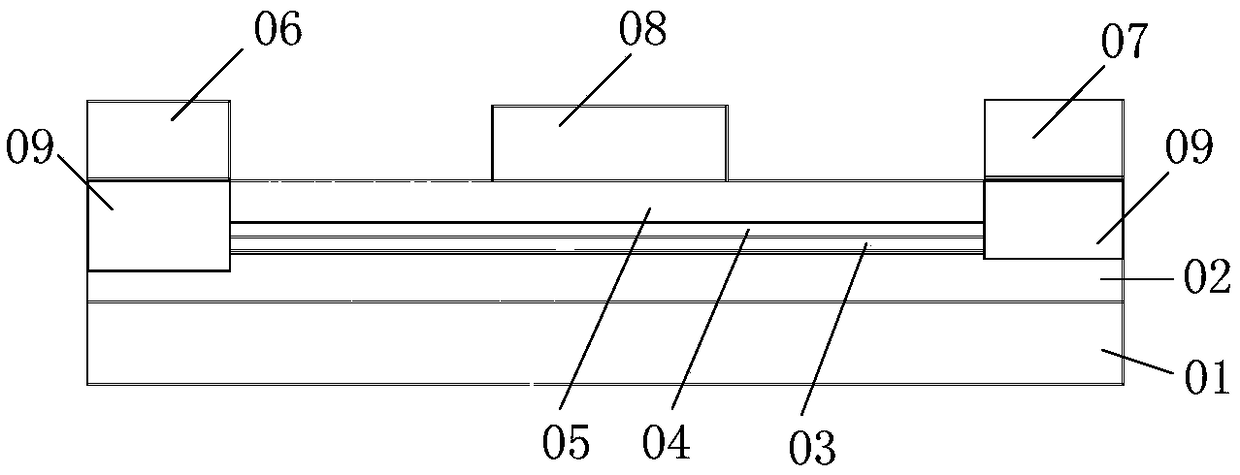

[0046] figure 1 The module structure of the high-speed transistor provided by the embodiment of the present invention is shown. For the convenience of description, only the parts related to the embodiment of the present invention are shown. The details are as follows:

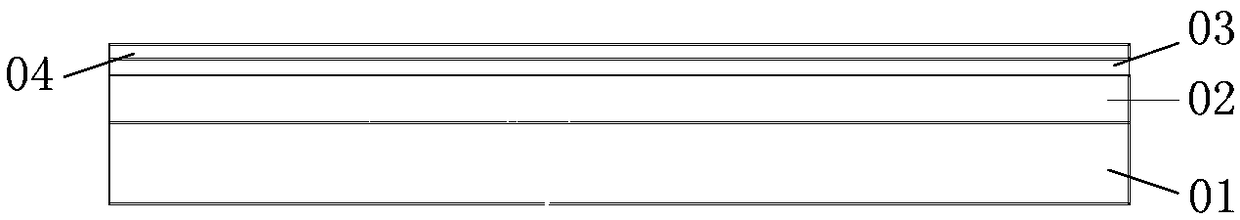

[0047] The high-speed transistor includes a substrate layer 01, a channel layer 02, a first non-doped (Al x Ga 1-x ) 2 o 3 Layer 03, highly doped (Al x Ga 1-x ) 2 o 3layer 04 , voltage modulation layer 05 , source electrode 06 , drain electrode 07 and gate electrode 08 .

[0048] Wherein, the channel layer 02 is arranged on the upper surface of the substrate layer 01; the first non-doped (Al x Ga 1-x ) 2 o 3 Layer 03 is arranged on the upper surface of chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com