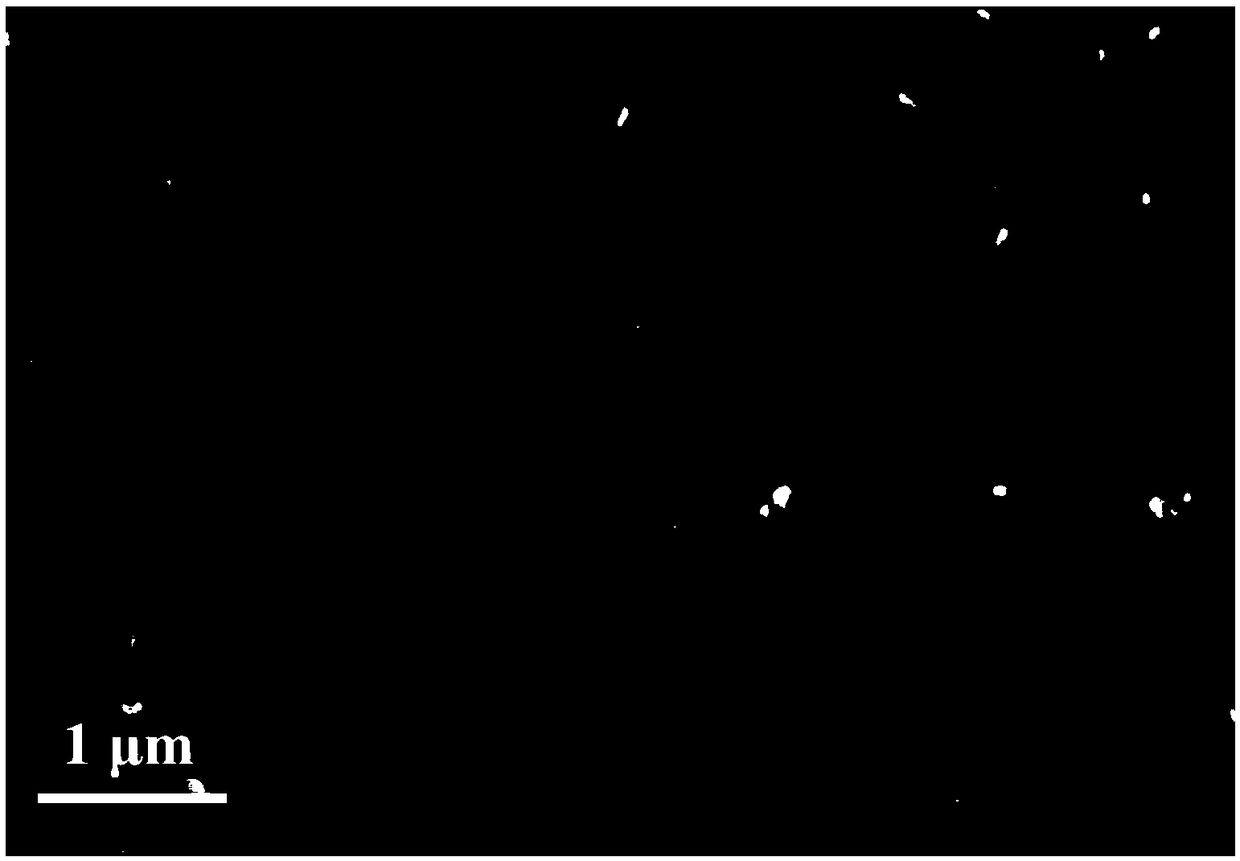

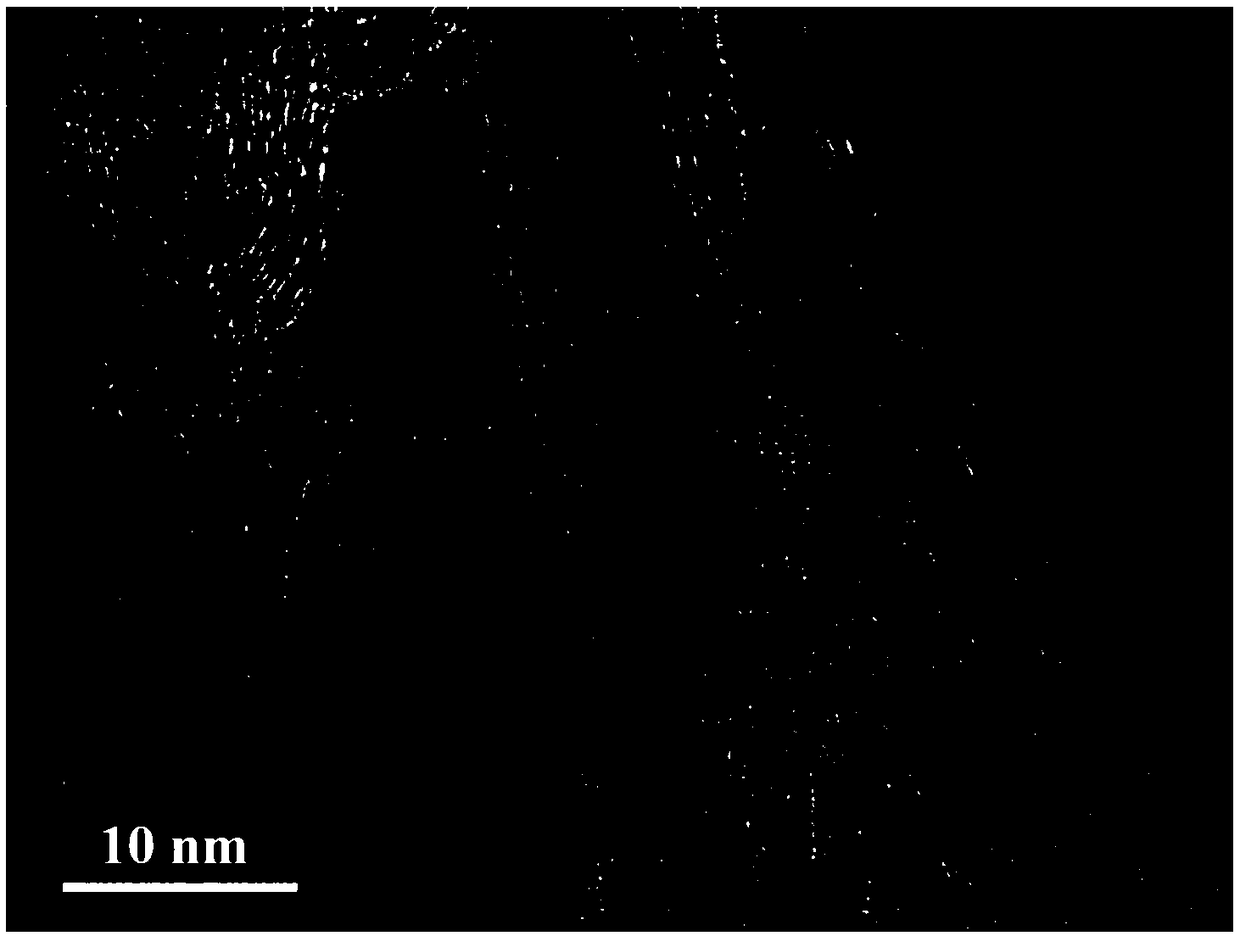

Composites of multi-walled carbon nanotubes and prussian blue analogues

A technology of multi-walled carbon nanotubes and Prussian blue, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of insignificant improvement of material Coulombic efficiency, decrease of specific capacity, and side reactions Intensify and other problems, to achieve the effect of excellent shape, high specific capacity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the composite material of the multi-walled carbon nanotube of above-mentioned structure and Prussian blue analogue is characterized in that comprising the following steps:

[0025] (1). TNWDIS is used as the carbon nanotube water-based dispersant, and the mass ratio of the dispersant and the multi-walled carbon nanotube is (0.2-0.5): 1, and the dispersant and the multi-walled carbon nanotube are dissolved in deionized water, Stir to form a solution, and then sonicate for 20 to 30 minutes until the mixture is evenly mixed to obtain a mixed solution;

[0026] (2). Potassium ferrocyanide / sodium ferrocyanide, sodium chloride and manganese chloride are used as precursors for preparing Prussian blue analogs, with ferrocyanide and manganese chloride molar ratio 1:1, chlorine The mass ratio of manganese oxide to multi-walled carbon nanotubes (4.8-6.0): 1, the mass ratio of sodium chloride to deionized water (0.34-0.36): 1, potassium ferrocyanide / sodium...

Embodiment 1

[0030] Weigh 0.08g TNWDIS and 0.16g multi-walled carbon nanotubes, dissolve the mixture in 100ml of deionized water, stir and dissolve with a magnetic stirrer at a stirring speed of 300r / min to form a solution, and then use a 400W ultrasonic Sonicate for 20min to form mixed solution A.

[0031] Weigh 2.12g potassium ferrocyanide, 34g sodium chloride and 0.99g MnCl 2 , adding potassium ferrocyanide to mixed solution A, stirring for 30 minutes to form mixed solution B, adding sodium chloride to mixed solution B to form sodium chloride saturated solution C, and continuing to stir for 30 minutes. MnCl 2 Dissolve in 100ml deionized water, stir evenly, add dropwise to the above saturated solution C, stir for 24h to form a suspension.

[0032] Use a centrifuge with a centrifugal speed of 8000r / min to collect the solid material in the suspension, wash with deionized water for 3 times until there is no remaining sodium chloride in the product, and dry at a temperature of 80°C to obta...

Embodiment 2

[0035]Weigh 0.07g TNWDIS and 0.16g multi-walled carbon nanotubes, dissolve the mixture in 100ml of deionized water, stir and dissolve with a magnetic stirrer at a stirring speed of 300r / min to form a solution, and then use a 400W ultrasonic Sonicate for 30 min to form a mixed solution A.

[0036] Weigh 2.12g potassium ferrocyanide, 34g sodium chloride and 0.99g MnCl 2 , adding potassium ferrocyanide to mixed solution A, stirring for 30 minutes to form mixed solution B, adding sodium chloride to mixed solution B to form sodium chloride saturated solution C, and continuing to stir for 30 minutes. MnCl 2 Dissolve in 100ml deionized water, stir evenly, add dropwise to the above saturated solution C, stir for 24h to form a suspension.

[0037] Use a centrifuge with a centrifugal speed of 8000r / min to collect the solid material in the suspension, wash with deionized water for 3 times until there is no remaining sodium chloride in the product, and dry at a temperature of 100°C to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com