Nickel-cobalt-manganese ternary positive electrode material and its preparation method and application, lithium-ion battery, electric vehicle

A positive electrode material and ternary material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of slow diffusion of lithium ions, further improvement of electrochemical performance, large secondary particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] According to a second aspect of the present invention, a method for preparing the above-mentioned nickel-cobalt-manganese ternary positive electrode material is provided, comprising the following steps:

[0058] (a) add manganese salt, ammoniacal liquor and lye simultaneously in the solution containing ammoniacal liquor, react and obtain manganese hydroxide suspension;

[0059] (b) adding nickel salt solution, cobalt salt solution and manganese salt solution with decreasing concentration to the manganese hydroxide suspension obtained in step (a) to carry out co-precipitation reaction to obtain the precursor of core-shell structure;

[0060] (c) mixing the precursor obtained in step (b) with a lithium source, and then sintering to obtain a nickel-cobalt-manganese ternary positive electrode material.

[0061] The present invention precipitates manganese hydroxide as the nucleus first, then precipitates nickel, cobalt, and manganese on this basis, and keeps the concentrati...

Embodiment 1

[0090] 1. Nickel-cobalt-manganese ternary cathode material

[0091] A nickel-cobalt-manganese ternary positive electrode material, the nickel-cobalt-manganese ternary positive electrode material has a core-shell structure, the core is a hollow core, and the core material is Li 2 MnO 3 , the shell material is LiNi 0.5 co 0.2 mn 0.3 o 2 ;

[0092] Among them, the contents of Ni, Co and Mn are distributed in a gradient in the shell material, the content of Mn gradually decreases from the inner layer to the outer layer, and the contents of Ni and Co gradually increase from the inner layer to the outer layer.

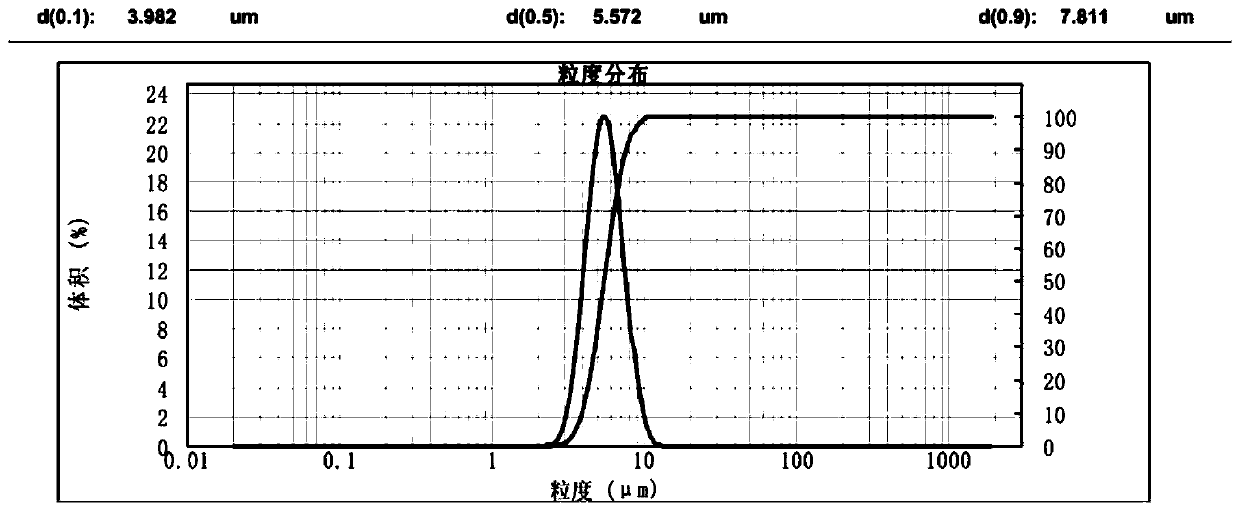

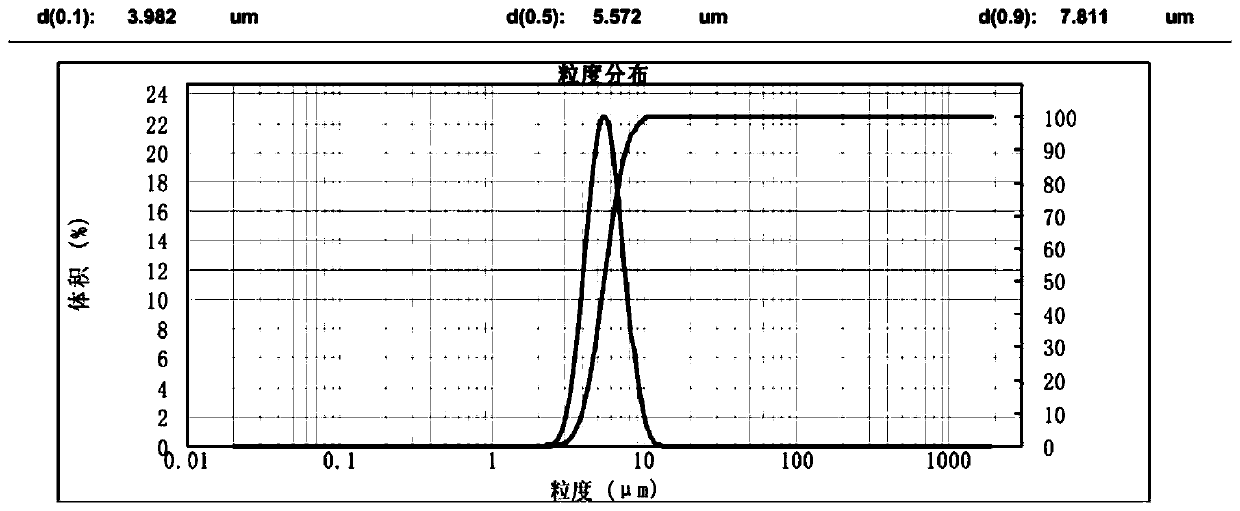

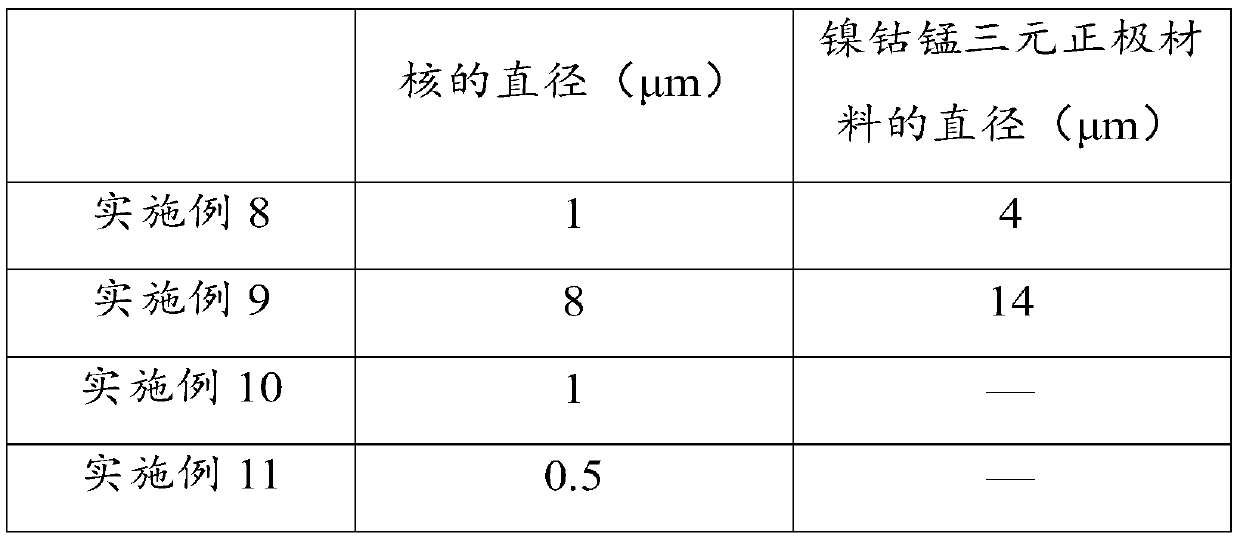

[0093] The diameter of the core of the hollow structure is 2 μm, and the obtained nickel-cobalt-manganese ternary positive electrode material is 5.6 μm.

[0094] The molar percentage of manganese in the nickel-cobalt-manganese ternary material of the innermost layer of the shell material is 50%, and the manganese in the nickel-cobalt-manganese ternary material of the o...

Embodiment 2

[0102] 1. Nickel-cobalt-manganese ternary cathode material

[0103] A nickel-cobalt-manganese ternary positive electrode material, the nickel-cobalt-manganese ternary positive electrode material has a core-shell structure, the core is a hollow core, and the core material is Li 2 MnO 3 , the shell material is LiNi 0.5 co 0.2 mn 0.3 o 2 ;

[0104] Among them, the contents of Ni, Co and Mn are distributed in a gradient in the shell material, the content of Mn gradually decreases from the inner layer to the outer layer, and the contents of Ni and Co gradually increase from the inner layer to the outer layer.

[0105] The diameter of the core of the hollow structure is 2 μm, and the obtained nickel-cobalt-manganese ternary positive electrode material is 5.6 μm.

[0106] The molar percentage of manganese in the nickel-cobalt-manganese ternary material of the innermost layer of the shell material is 50%, and the manganese in the nickel-cobalt-manganese ternary material of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com