Solid polymer electrolyte, preparation method thereof and lithium ion battery

A solid polymer and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high polarity on the surface of inorganic nanoparticles, affecting the performance of polymer electrolytes, and the decline in ionic conductivity, so as to inhibit dendrites Growth, avoiding battery short circuit, and improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a method for preparing a solid polymer electrolyte, comprising the following steps:

[0054] A) Ultrasonic treatment of the graphene oxide solution, and suction filtration to obtain a three-dimensional graphene oxide film;

[0055] B) freeze-drying the three-dimensional graphene oxide film;

[0056] C) drop-coating a mixed solution of a lithium salt electrolyte and a polymer onto the freeze-dried three-dimensional graphene oxide film, and drying in a vacuum to obtain a solid polymer electrolyte;

[0057] The polymer is one or more of PEO, PAN, PVDF, PMMA and PVDF-HFP;

[0058] The lithium salt electrolyte is LiTFSI, LiPF 6 、LiCIO 4 one or more of

[0059] The polymer has electron-donating functional groups, and the molar ratio of the electron-donating functional groups to lithium ions in the lithium salt is (1-10):1.

[0060] In the present invention, the graphene oxide solution is preferably ultrasonically treated, and then a mo...

Embodiment 1

[0078] 50 mL of graphene oxide solution with a concentration of 1 mg / mL was sonicated for 1 h, and 10 mL of the solution was suction-filtered to form a three-dimensional graphene oxide film (thickness: 50 μm), which was taken out and freeze-dried at -100°C for 48 h.

[0079] Take 0.1625g of LiTFSI (lithium bistrifluoromethanesulfonylimide), add it into 5mL of acetonitrile solution and stir to dissolve, then add 0.2g of PEO (polyethylene oxide) into the above mixed solution and stir for 6h until completely dissolved to obtain solution A (where EO:Li=2:1).

[0080] The three-dimensional graphene oxide was cut into sheets with a diameter of 20 mm, arranged on a PET substrate, and the obtained solution A was drip-coated on the graphene oxide film, and vacuum-dried for 24 hours to obtain a solid polymer electrolyte membrane.

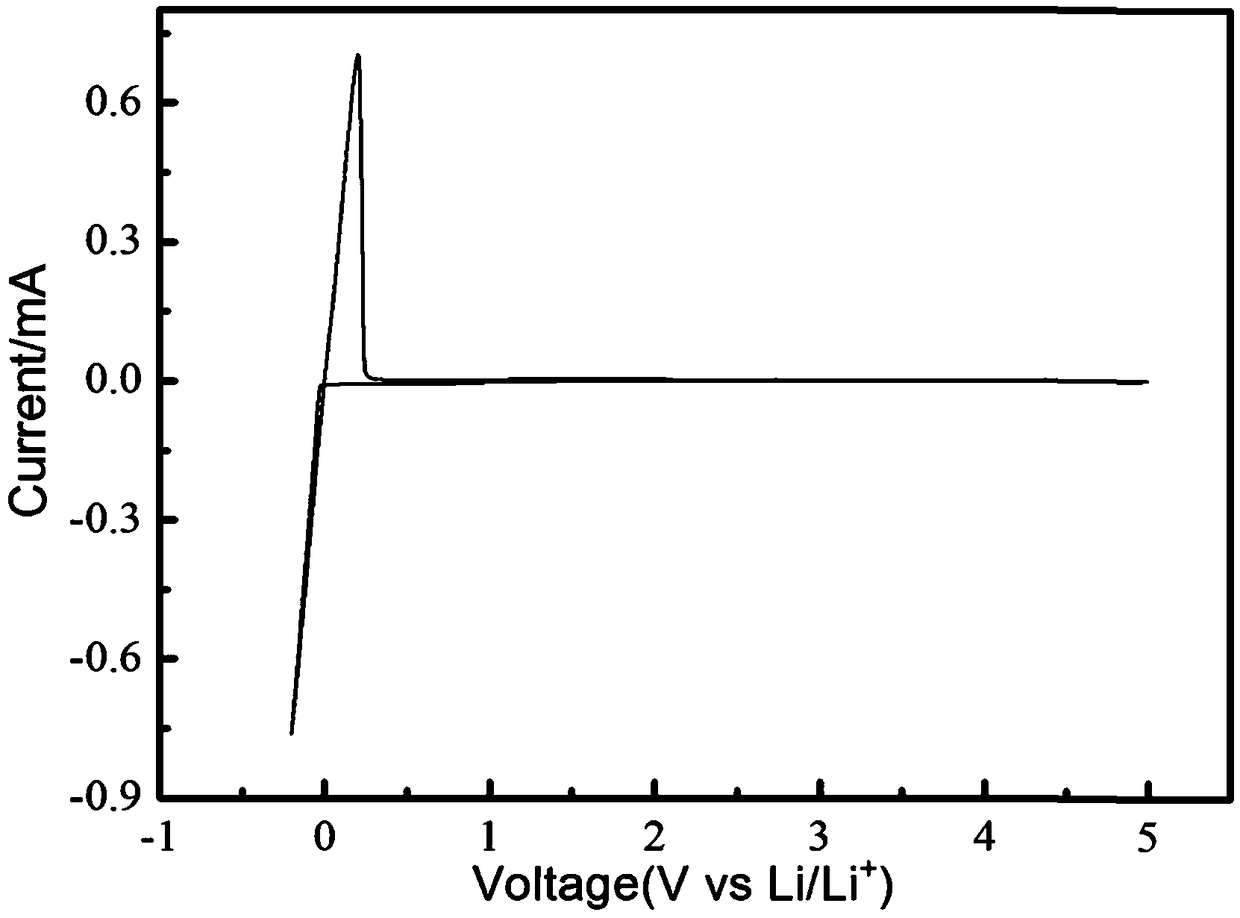

[0081] The prepared polymer electrolytes were assembled into half cells for performance testing.

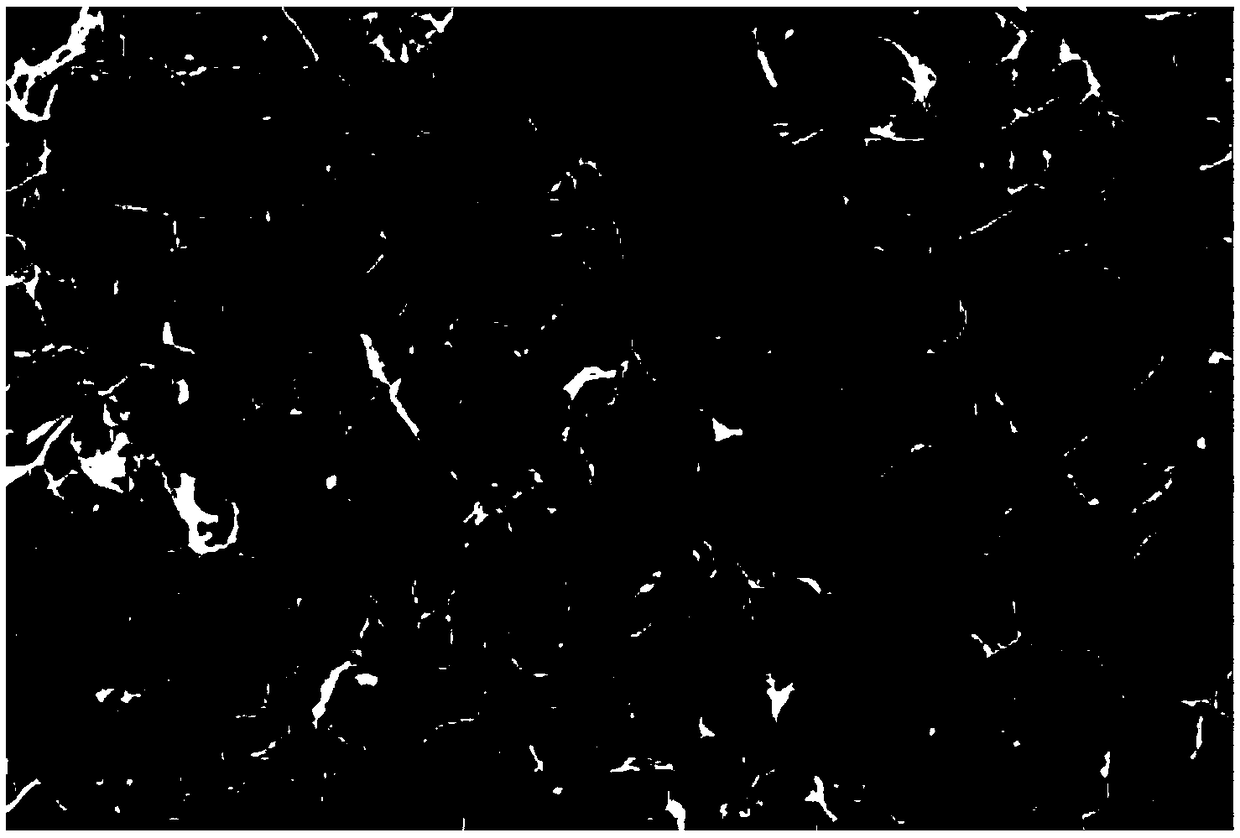

[0082] figure 1 It is the SEM picture of the three-dimen...

Embodiment 2

[0087] Sonicate 50 mL of graphene oxide solution with a concentration of 1 mg / mL for 1 h, then add 5 g of polyethylene glycol n-hexadecyl ether, stir for 2 h, take 5 mL of the solution and suction filter it into a three-dimensional oxide film (thickness 50 μm), take it out and freeze-dry it. The temperature is -100°C, and the time is 48h.

[0088] Take 0.1625g of LiTFSI (lithium bistrifluoromethanesulfonylimide), add it into 5mL of acetonitrile solution and stir to dissolve, then add 0.1g of PEO (polyethylene oxide) into the above mixed solution and stir for 6h until completely dissolved to obtain solution A (where EO:Li=4:1).

[0089] The prepared three-dimensional graphene oxide membrane was cut into sheets with a diameter of 20 mm, arranged on a PET substrate, and the obtained solution A was drip-coated on the graphene oxide membrane, and dried in vacuum for 24 hours to obtain a solid polymer electrolyte membrane.

[0090]The prepared polymer electrolyte was removed from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com