A region coated end cap group for suppressing mode instability and application thereof

An end cap and area technology, applied in the field of fiber laser, can solve the problems of loss of high-order modes and suppression mode instability, and achieve the effect of suppressing the generation of high-order modes and suppressing mode instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

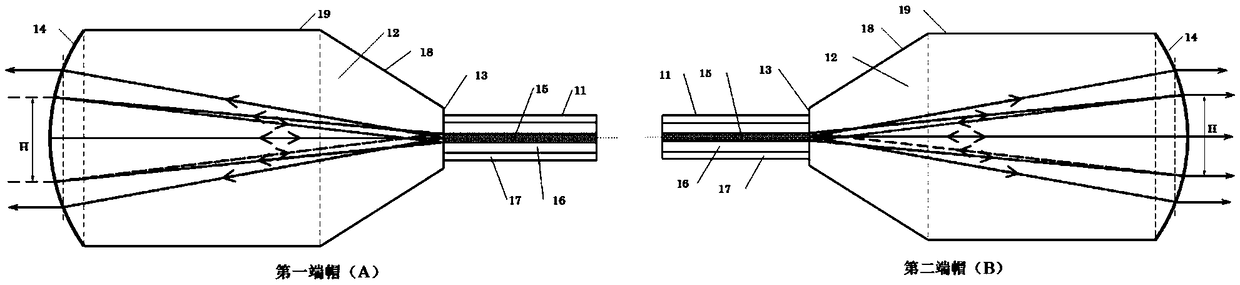

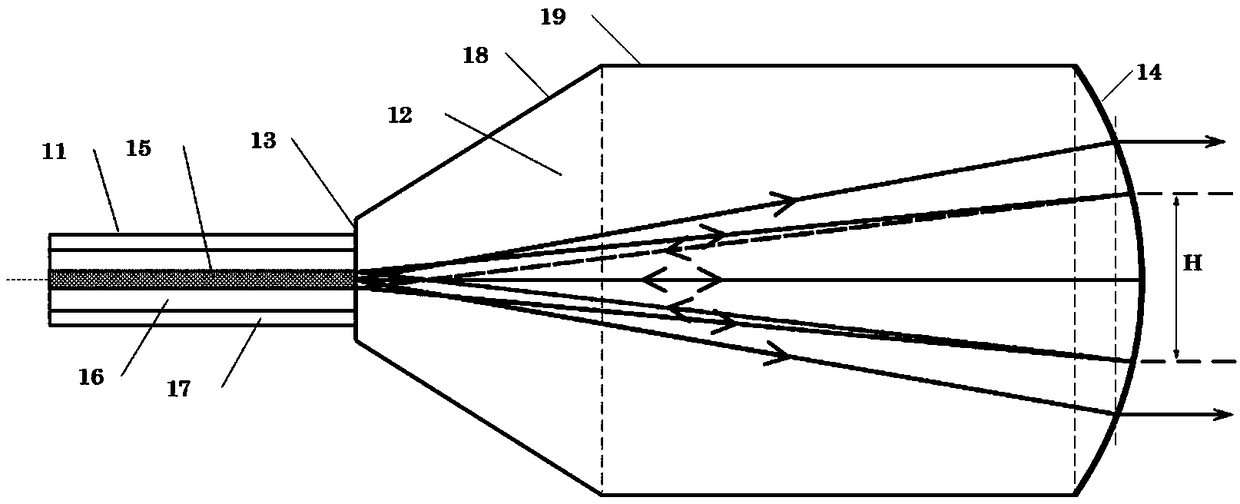

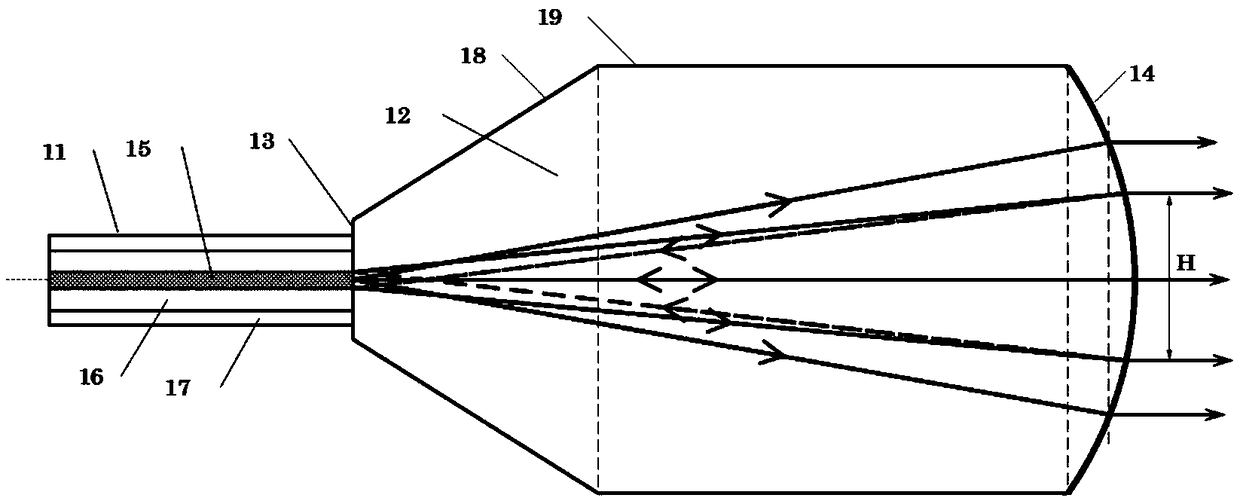

[0025] A regional coating end cap group with unstable suppression mode, the structure diagram is as follows figure 1 As shown, including the first end cap A and the second end cap B, the first end cap A and the second end cap B both include the following structures, respectively as figure 2 with 3Shown: optical fiber 11, specially designed quartz block 12: the optical fiber 11 can be a double-clad optical fiber consisting of a core 15, an inner cladding 16 and an outer cladding 17, or a single-clad optical fiber consisting of a core 15 , cladding 17; Quartz block 12 is an integral structure formed by successively connecting circular frustum 18, cylinder 19 and output curved surface body 14 with the same size of the connecting end face; The smaller end face of 18) becomes an interface 13 after welding; after the laser is transmitted from the fiber core 15 to the interface 13, it enters the quartz block 12, and after the laser beam passes through the area of the round table ...

Embodiment 2

[0027] A regional coating end cap group with unstable suppression mode, its structure is basically the same as that of Embodiment 1, the difference is that the spatial region corresponding to the base mode on the curved surface of the output curved surface body 14 in the first end cap A is coated with a high reflection film, and the specific reflectivity The value is 100%, no transmitted light, the area outside the fundamental mode is coated with an anti-reflection coating, the transmittance is 100%, and the laser light is completely transmitted; the output surface body 14 in the second end cap B is coated with a 10% reflective film on the corresponding space area of the fundamental mode, 90 % antireflection coating, the area outside the base mode is coated with antireflection coating, the transmittance is 100%, and the laser light is completely transmitted.

Embodiment 3

[0029] An all-fiber oscillator using a wavelength-coated end cap group that suppresses stimulated Raman scattering, its structure is as follows Figure 4 As shown, it includes a first end cap A, a second end cap B, a rare earth particle-doped gain fiber 23, a pump signal beam combiner 24, a fiber-coupled semiconductor laser 25, a signal energy transmission fiber 26, and a pump energy transmission fiber 27 The signal energy transmission fiber 26 connects the first end cap A, the pump signal combiner 24, the rare earth particle gain fiber 23 and the second end cap B sequentially; the pump signal combiner 24 has one or A plurality of pumping arms, a signal input arm, and a signal output arm; a group of fiber-coupled semiconductor lasers 25 are connected to the pumping arm of the pumping signal beam combiner 24 through the pumping energy transmission fiber 27; the first end cap The structures of A and the second end cap B are as shown in Example 1, and the dimensions of the compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com