Preparation method of ovalbumin emulsion having double-shell structure

A technology of ovalbumin and shell structure, which is applied in the field of ovalbumin emulsion, can solve the problems of poor emulsifying activity and emulsifying stability, thin shell structure, and poor emulsifying properties of the emulsion, and achieve good emulsifying activity and emulsifying stability of the emulsion, and stable storage The effect of good performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation of oily core material:

[0032] Preparation of emulsion core material: prepare 10% (w / v) glutathione aqueous solution, add it to triglycerides of the same quality, add 4% (w / w) soybean lecithin as emulsifier, and use it at a high speed at 15000r / min Disperse for 3 minutes to prepare W / O emulsion, which is added as glutathione emulsion core material (oily core material).

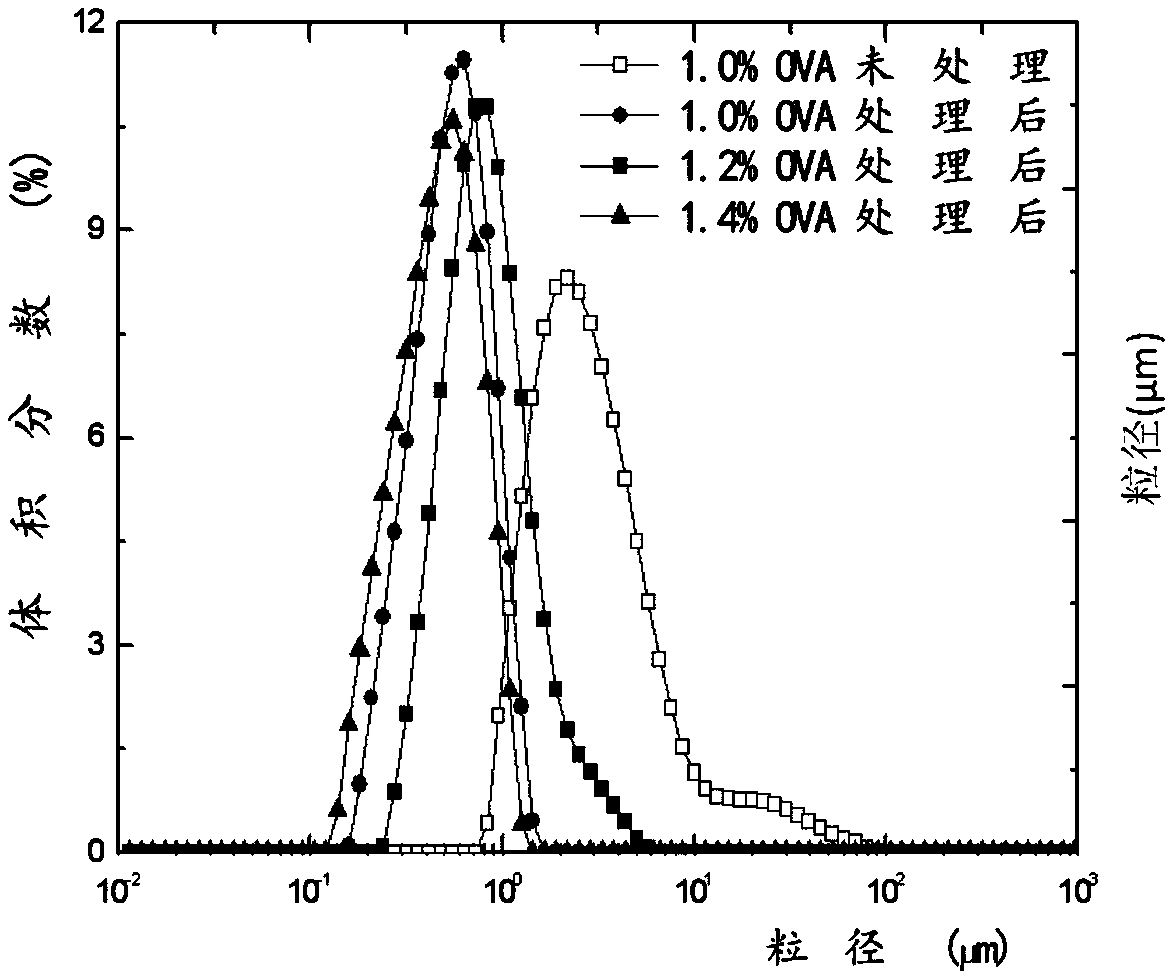

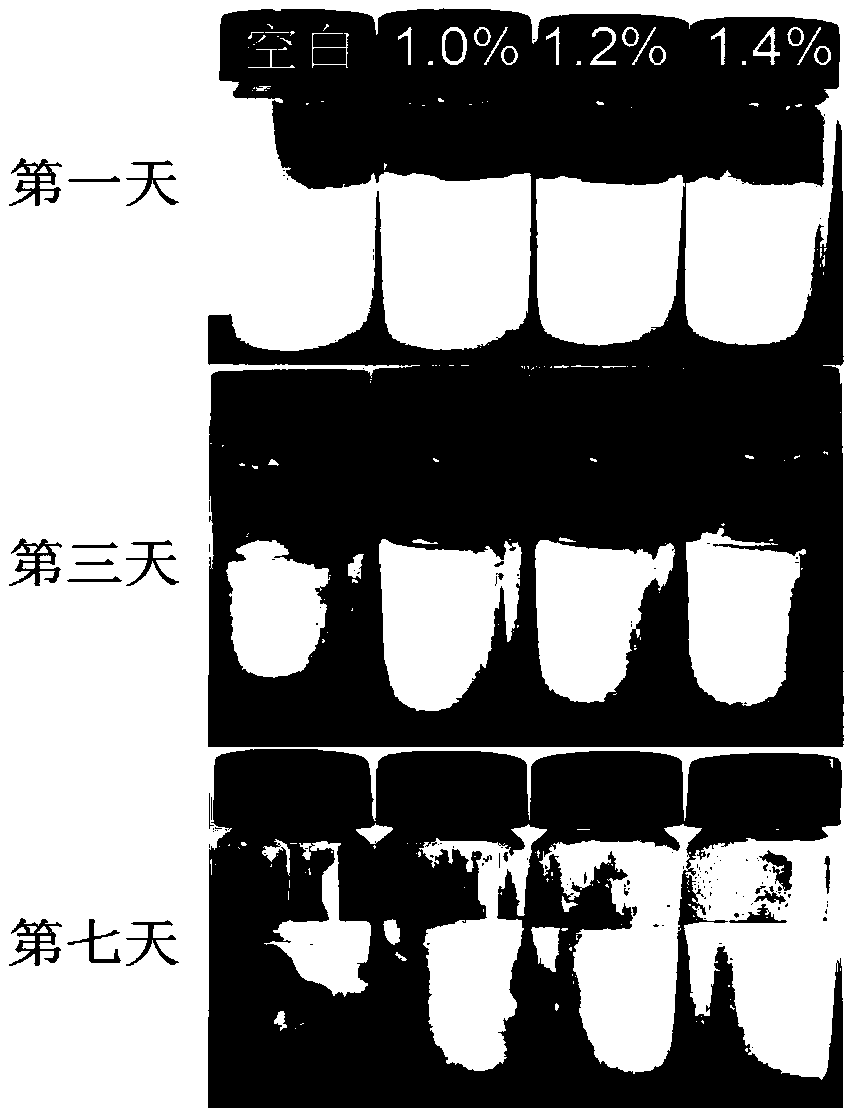

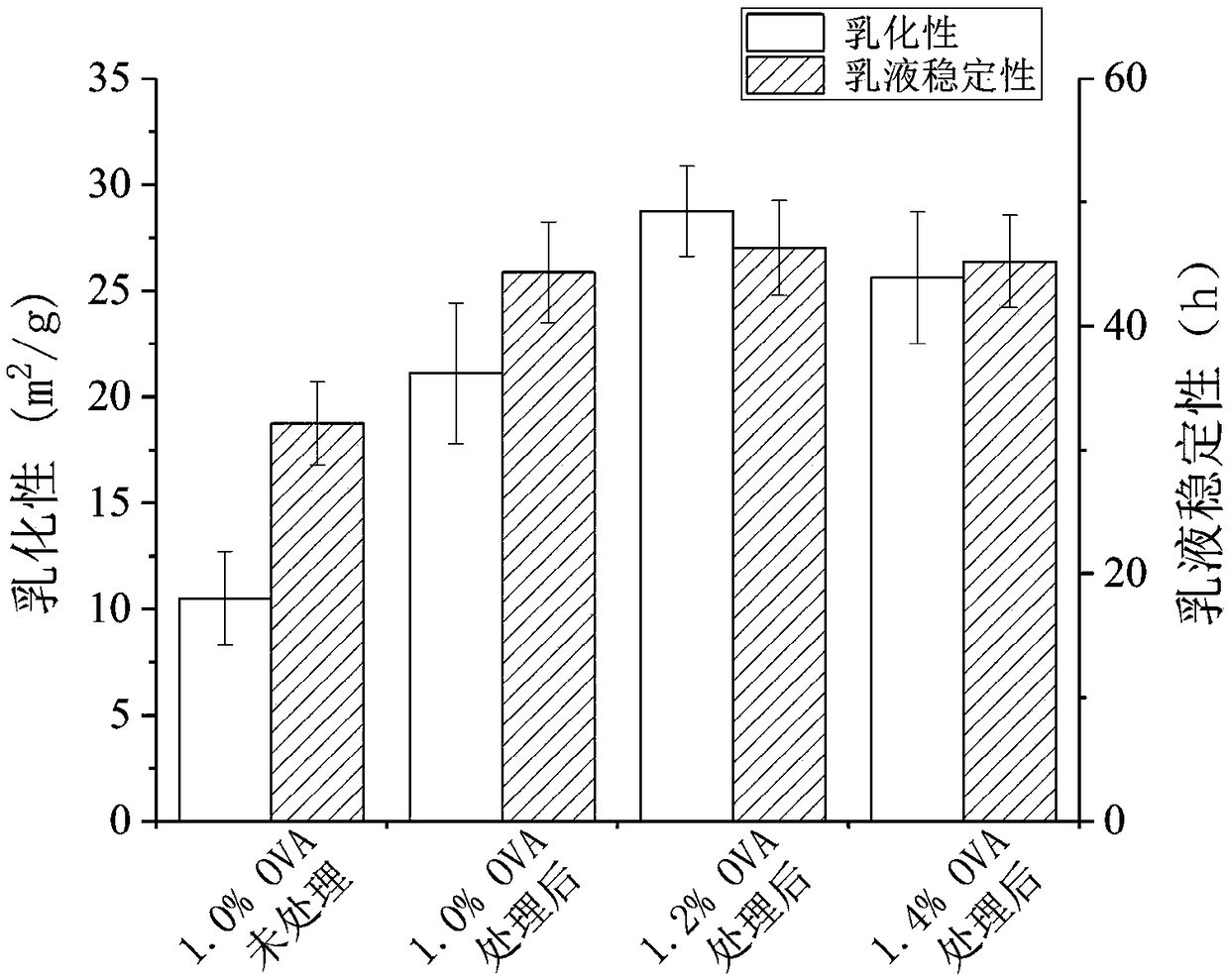

Embodiment 1

[0034] (1) Dissolve ovalbumin in water, add inulin after magnetic stirring and dissolving, and obtain an ovalbumin-inulin solution after ultrasonic treatment, so that the concentration of ovalbumin is 1.0% w / w and the concentration of inulin is 1.0% w / w , magnetic stirring frequency is 30rpm / min, ultrasonic intensity is 180W / cm 2 , the ultrasonic time is 1h;

[0035] (2) Add the oily core material to the ovalbumin-inulin solution, place it under a high-speed shearer and shear it, and then homogenize the high-pressure micro-jet several times to obtain an emulsion. The concentration of the oily core material in the emulsion is 5%. w / w, the speed of the high-speed shearing instrument is 20000rpm / min, the shearing time is 1min, and the homogeneous pressure of the high-pressure microjet is controlled to 11kPa. ;

[0036] (3) Load the iron ion of ferrous fumarate onto the emulsion droplet surface of the emulsion by ion exchange to obtain a mixed solution. In the mixed solution, th...

Embodiment 2

[0040] (1) Dissolve ovalbumin in water, add inulin after magnetic stirring and dissolving, and obtain an ovalbumin-inulin solution after ultrasonic treatment, so that the concentration of ovalbumin is 1.2% w / w, and the concentration of inulin is 1.2% w / w , magnetic stirring frequency is 35rpm / min, ultrasonic intensity is 190W / cm 2 , the ultrasonic time is 1.5h;

[0041] (2) Add the oily core material to the ovalbumin-inulin solution, place it under a high-speed shearing instrument and shear it, and then homogenize it several times with high-pressure micro-jet flow to obtain an emulsion. The concentration of the oily core material in the emulsion is 10%. w / w, the speed of the high-speed shearer is 23000rpm / min, the shearing time is 2min, and the homogeneous pressure of the high-pressure microjet is controlled to 12kPa. ;

[0042] (3) Load the iron ion of ferrous fumarate onto the emulsion droplet surface of the emulsion by ion exchange to obtain a mixed solution. In the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com