Lithium polyacrylate, preparation method and uses thereof, and lithium ion battery

A technology for lithium polyacrylate and lithium ion batteries, which is applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of unfavorable lithium ion and electron transmission, high cost, and complicated operation process, and achieves the advantages of transmission and prevention of damage. , to avoid worsening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The present embodiment provides a kind of lithium polyacrylate, and its preparation method is as follows:

[0053] Take a polyacrylic acid solution with a molecular weight of 250,000 and a mass fraction of 30%, and dilute it to a polyacrylic acid solution with a mass fraction of 20% with deionized water;

[0054] Use lithium hydroxide to adjust the diluted polyacrylic acid solution to a pH of 7, specifically: put lithium hydroxide into a polyacrylic acid solution with a mass fraction of 20%, ultrasonically, until the lithium hydroxide is completely dissolved, test the pH of the solution When it was 7, lithium polyacrylate was obtained, and the obtained lithium polyacrylate was sealed and sealed for subsequent use.

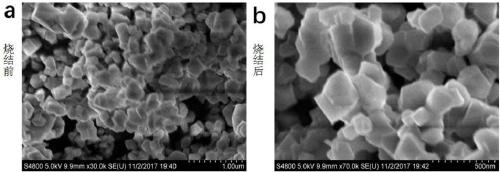

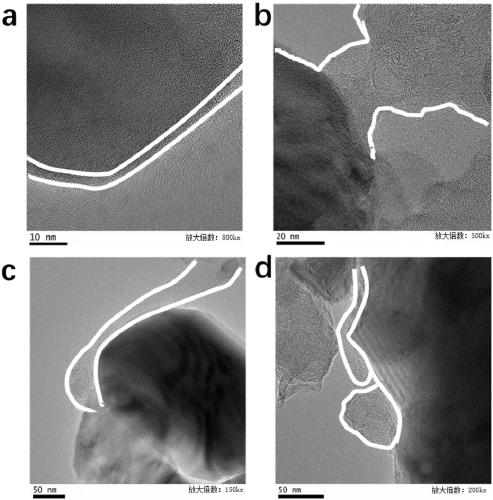

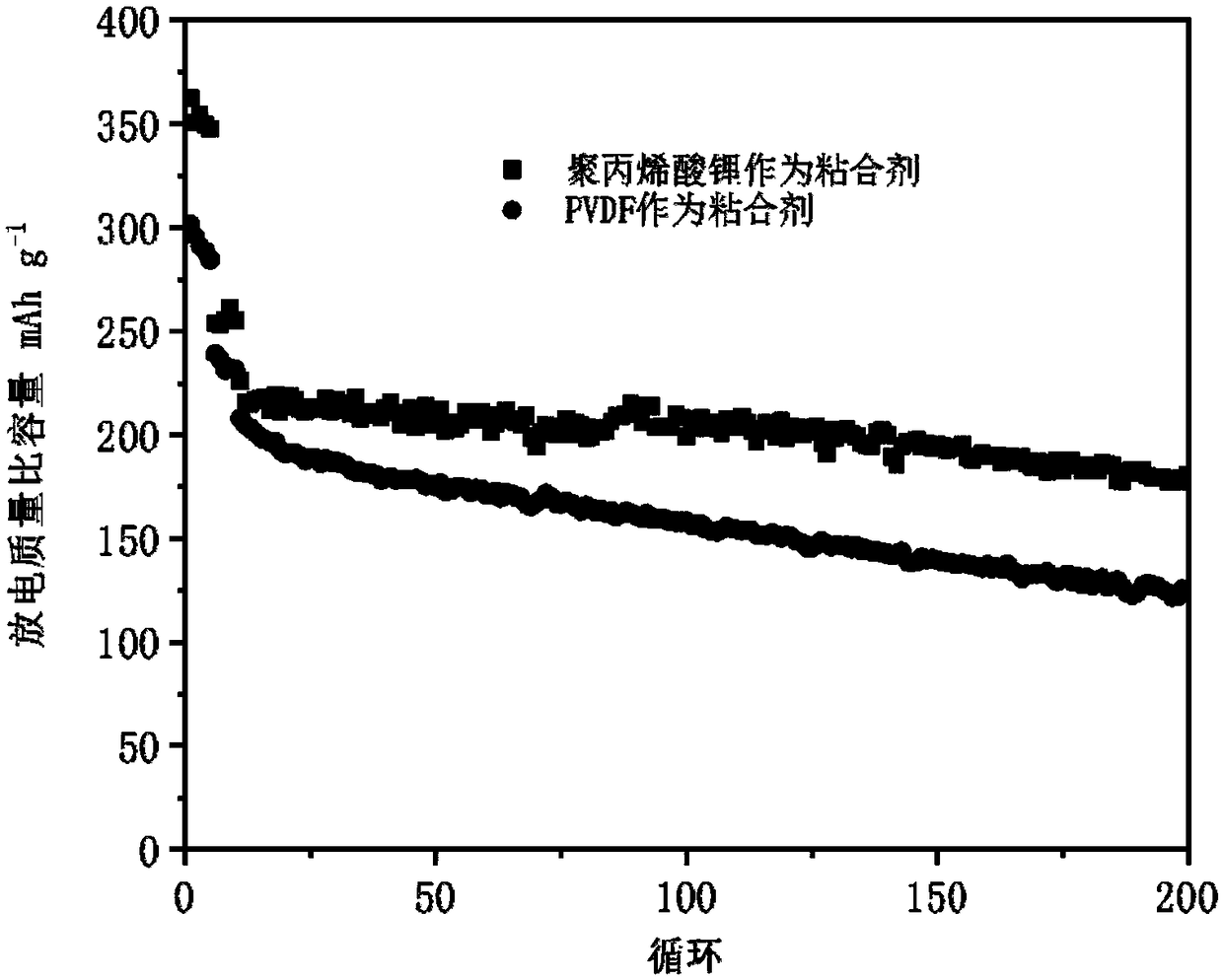

[0055] This embodiment also provides a lithium-ion battery, which includes an electrode material and a binder, wherein the electrode material includes a lithium-rich manganese-based positive electrode material, specifically Li 1.2 Ni 0.13 co 0.13 mn 0.54...

Embodiment 2

[0057] The present embodiment provides a kind of lithium polyacrylate, and its preparation method is as follows:

[0058] Take a polyacrylic acid solution with a molecular weight of 250,000 and a mass fraction of 30%, and dilute it to a polyacrylic acid solution with a mass fraction of 20% with deionized water;

[0059] Use lithium hydroxide to adjust the diluted polyacrylic acid solution to a pH of 5, specifically: put lithium hydroxide into a polyacrylic acid solution with a mass fraction of 20%, ultrasonically, until the lithium hydroxide is completely dissolved, test the pH of the solution When it was 5, lithium polyacrylate was obtained, and the obtained lithium polyacrylate was sealed and sealed for subsequent use.

[0060] This embodiment also provides a lithium-ion battery, which includes an electrode material and a binder, wherein the electrode material includes a lithium-rich manganese-based positive electrode material, specifically Li 1.2 Ni 0.13 co 0.13 mn 0.54...

Embodiment 3

[0062] The present embodiment provides a kind of lithium polyacrylate, and its preparation method is as follows:

[0063] Take a polyacrylic acid solution with a molecular weight of 250,000 and a mass fraction of 30%, and dilute it to a polyacrylic acid solution with a mass fraction of 20% with deionized water;

[0064] Use lithium hydroxide to adjust the diluted polyacrylic acid solution to a pH of 6, specifically: put lithium hydroxide into a polyacrylic acid solution with a mass fraction of 20%, ultrasonically, until the lithium hydroxide is completely dissolved, test the pH of the solution When it was 6, lithium polyacrylate was obtained, and the obtained lithium polyacrylate was sealed and sealed for subsequent use.

[0065] This embodiment also provides a lithium-ion battery, which includes an electrode material and a binder, wherein the electrode material includes a lithium-rich manganese-based positive electrode material, specifically Li 1.2 Ni 0.13 co 0.13 mn 0.54...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com