Water soluble anti-yellowing agent used for high water absorbent resin

A technology of superabsorbent resin and anti-yellowing agent, applied in the field of water-soluble anti-yellowing agent, to achieve the effect of easy-to-obtain raw materials, stable performance and low price

Inactive Publication Date: 2019-01-22

ZHEJIANG SATELLITE PETRO CHEM CO LTD

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] At present, there are few reports on water-soluble anti-yellowing agents, and there is a blank in the application of superabsorbent resins. Therefore, according to the storage conditions and application fields of superabsorbent resins, anti-yellowing agents are developed to achieve good anti-yellowing properties. Yellowing properties are important

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

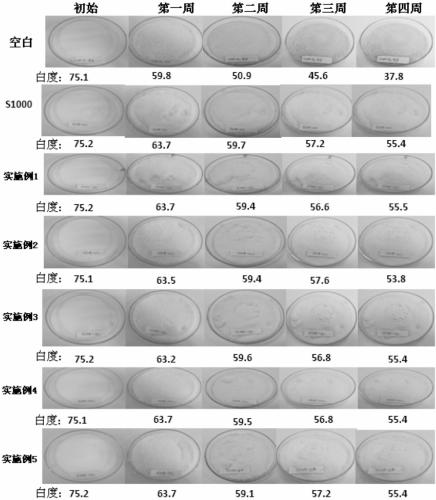

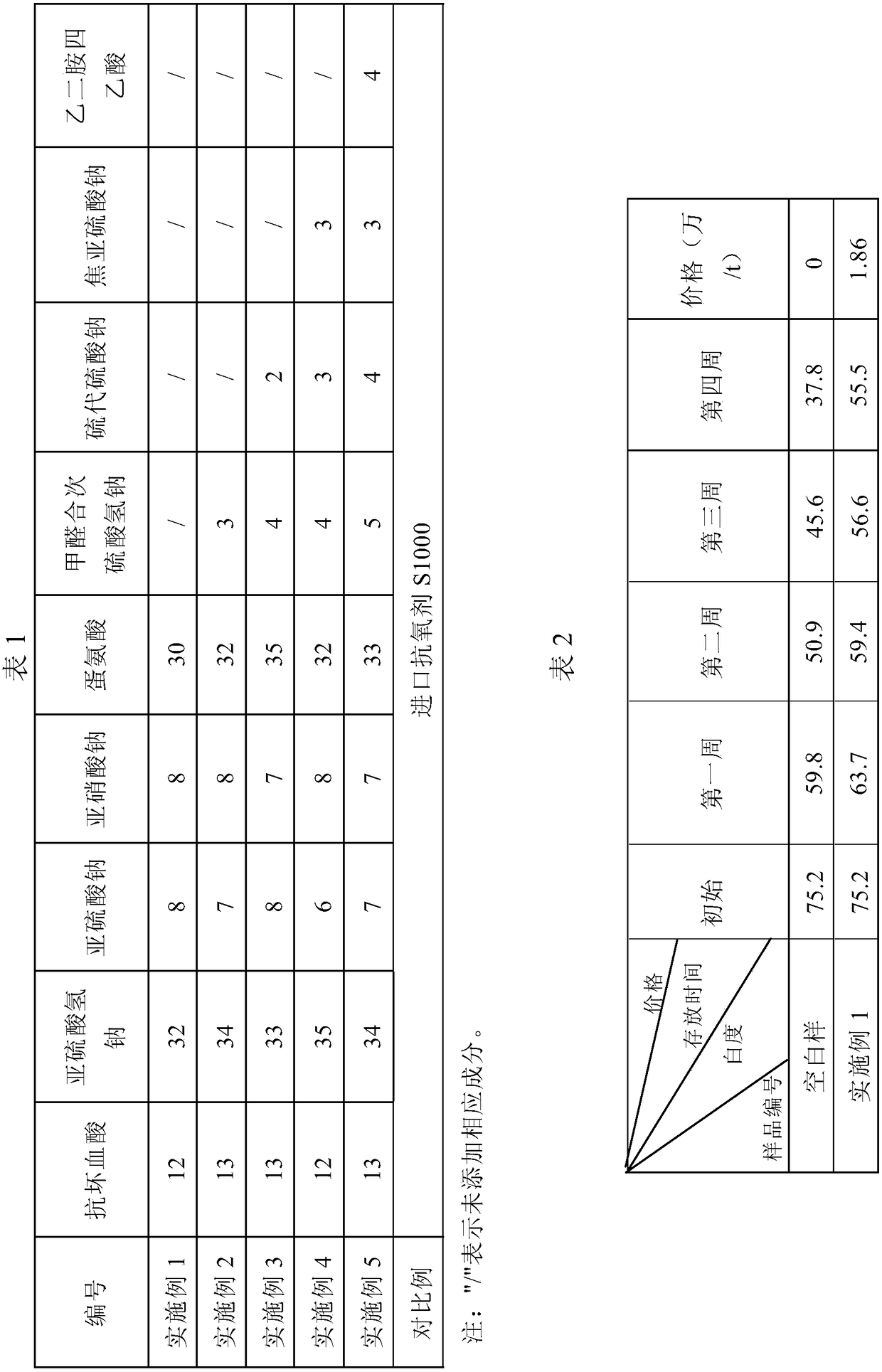

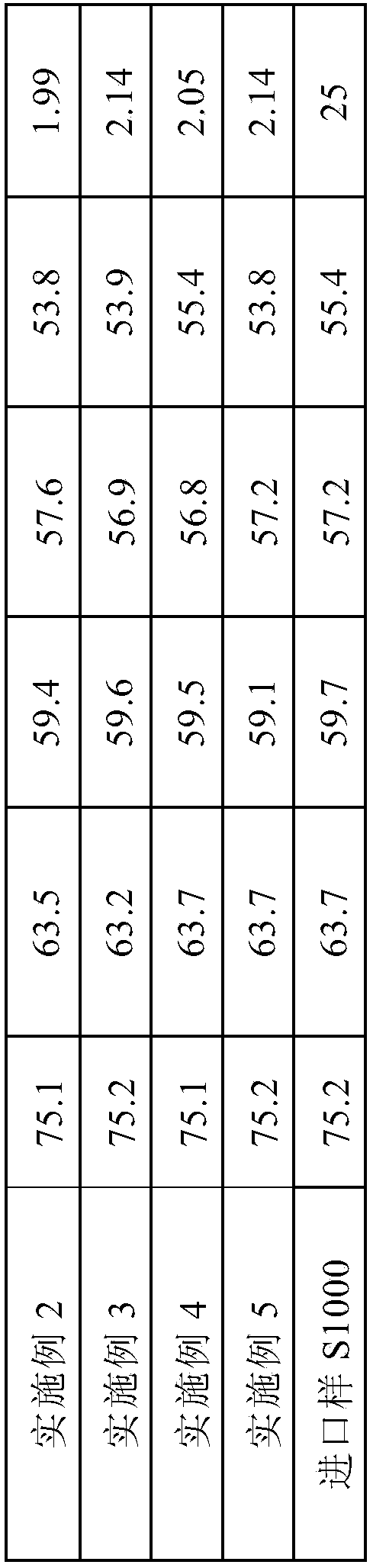

[0022] According to the content (parts by weight) of each component listed in Table 1, the water-soluble reducing agent is weighed according to the shown requirements, then pulverized, and then mixed evenly under stirring in a solid mixing tank to obtain a powdery water-soluble anti-yellowing agent agent.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a water soluble anti-yellowing agent used for high water absorbent resin. The water soluble anti-yellowing agent used for high water absorbent resin comprises, by weight, 10 to15 parts of ascorbic acid, 30 to 35 parts of sodium bisulfite, 5 to 10 parts of sodium sulfite, 5 to 10 parts of sodium nitrite, and 20 to 40 parts of methionine. According to a preparation method, areducing agent is adopted for preparation of the water soluble anti-yellowing agent, yellowing of acrylic acid high water absorbent resins in storage process is inhibited, the raw materials are easily available, the performance is stable, the water soluble anti-yellowing agent is green and is friendly to the environment, and the anti-yellowing agent cost is reduced by 90% or more.

Description

technical field [0001] The invention belongs to the technical field of anti-yellowing agents, and in particular relates to a water-soluble anti-yellowing agent for superabsorbent resins. Background technique [0002] Super Absorbent Resin (SAR for short), also known as "Super Absorbent Polymer" (SAP for short), "Super Absorbent Polymer", "Super Absorbent", etc. With a slightly cross-linked three-dimensional network structure, it can absorb and retain hundreds or even thousands of times its own weight in water. It is widely used in baby diapers, women's hygiene products, adult incontinence pads, agricultural and forestry water conservation, and desert control. Applications. [0003] The production process of superabsorbent resin needs to use refined acid, refined acid contains polymerization inhibitor MEHQ (50 ~ 200ppm), MEHQ belongs to phenolic substances, under certain humidity, temperature and oxygen, it will be oxidized into quinones The substance is brownish-yellow, wh...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08K13/02C08K5/1535C08K3/30C08K3/28C08K5/378C08K5/17

CPCC08K3/28C08K3/30C08K5/1535C08K5/175C08K5/378C08K13/02C08K2003/3045C08K2201/014

Inventor 靳琳琳杨卫东沈晓炜

Owner ZHEJIANG SATELLITE PETRO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com