Use method of circulating fluidized bed rectification device for preparing hydrogen fluoride

A circulating fluidized bed, hydrogen fluoride technology, applied in hydrogen fluoride, fluorine/hydrogen fluoride, chemical instruments and methods, etc., can solve the problems of non-corrosion resistance of column internals, high gas film mass transfer coefficient, gas flow pressure drop, etc. The effect of improving thermodynamic efficiency, large liquid film mass transfer coefficient, and reducing reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

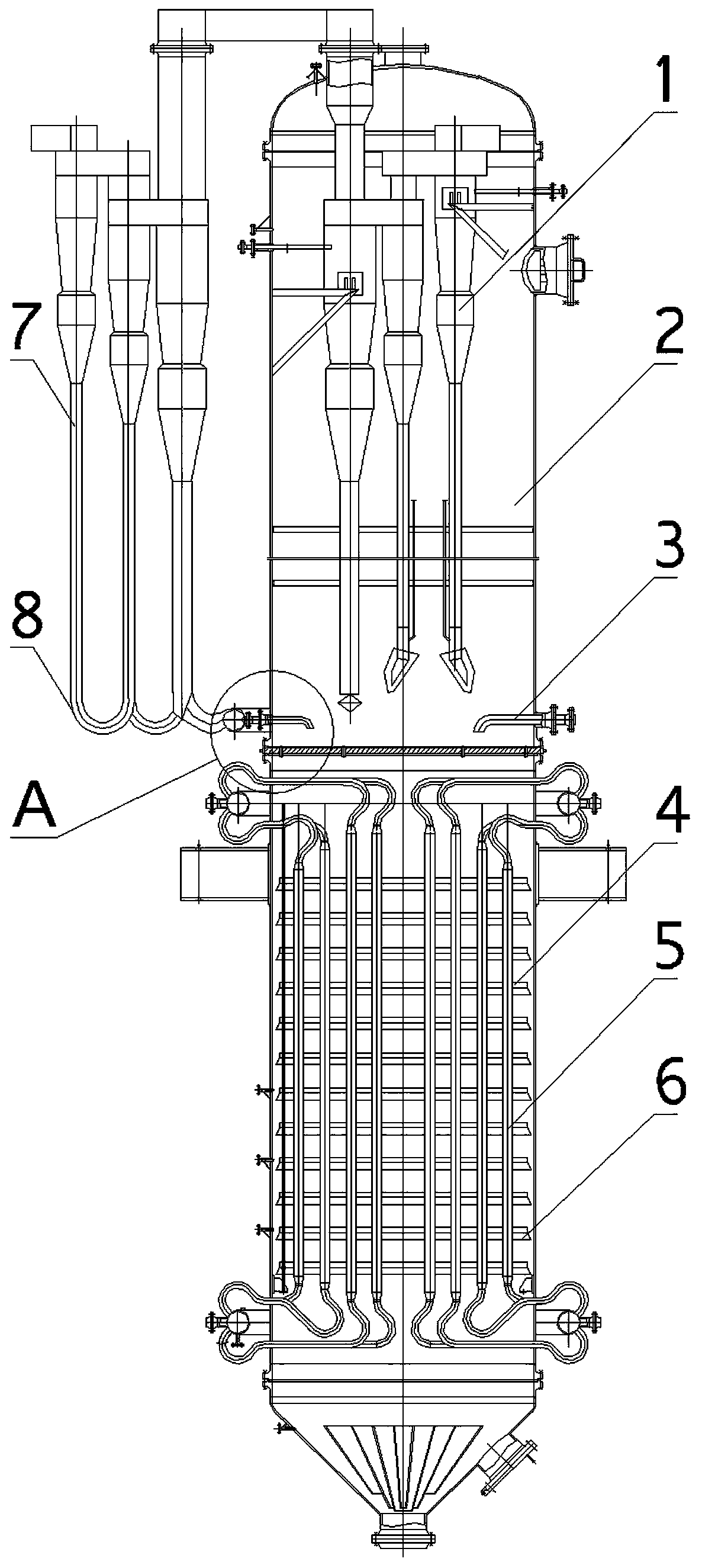

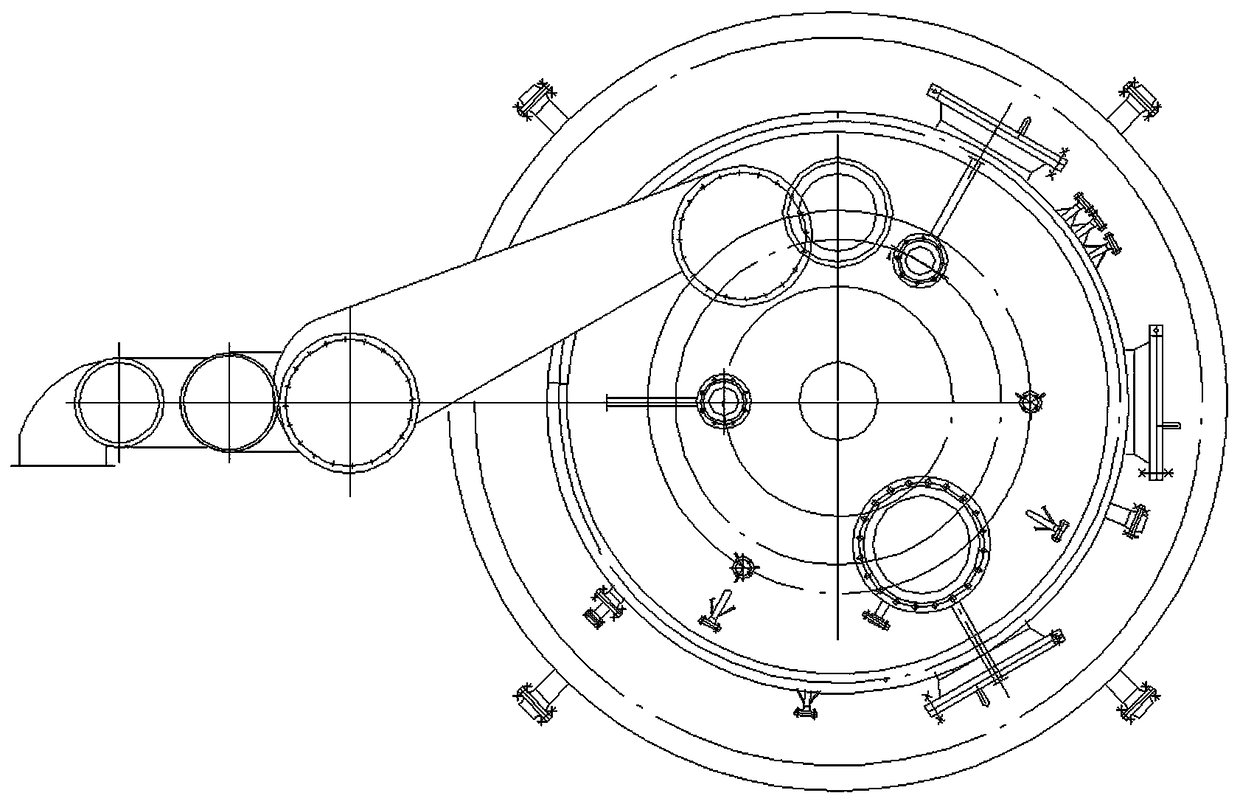

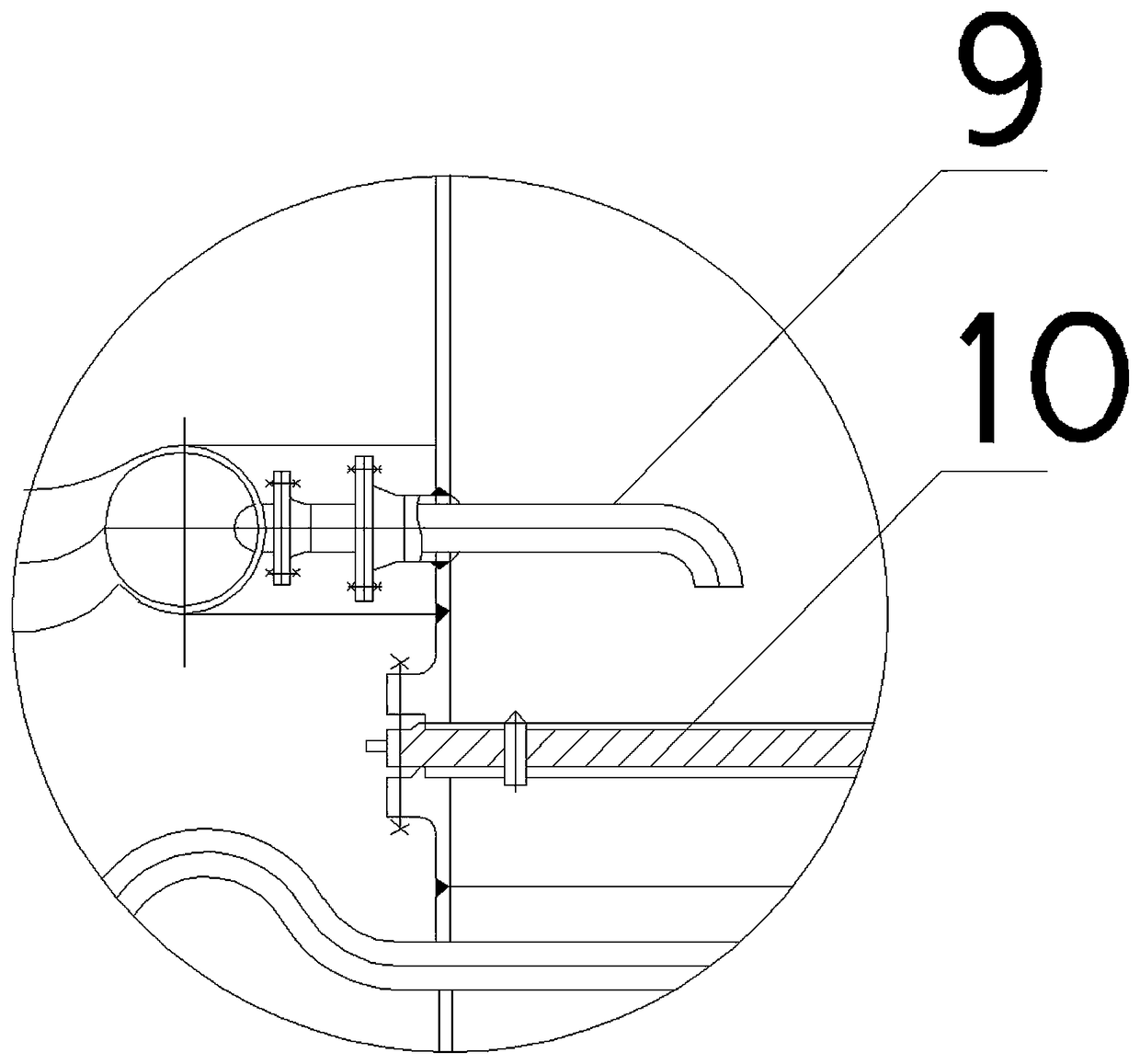

[0020] Such as figure 1 , figure 2 , image 3 Shown, a kind of using method of preparing hydrogen fluoride circulating fluidized bed rectification device is characterized in that:

[0021] Step 1. Before use, the liquid level of the U-shaped liquid seal 8 at the bottom of the multi-stage cyclone condenser II7 must be observed through the liquid level gauge to ensure that the liquid level is at least 300mm higher than the return pipe 9 and that the U-shaped liquid seal 8 is in a normal working state. .

[0022] Step 2, the crude hydrofluoric acid liquid enters from the feed liquid conduit 3 designed in the middle of the circulating fluidized bed rectification tower body 2, injects into the liquid receiving pan 10, the injection temperature is 9°C, and the crude hydrofluoric acid liquid is evenly distributed through the liquid pan 10 After d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com