Anode carbon block slotting device

A technology of anode carbon block and slotting equipment, which is applied in stone processing equipment, stone processing tools, working accessories, etc., can solve the problems of high cutting noise decibels, high sawtooth scrap rate, unfavorable production and use, etc., to reduce workload, Sound insulation effect is good, the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

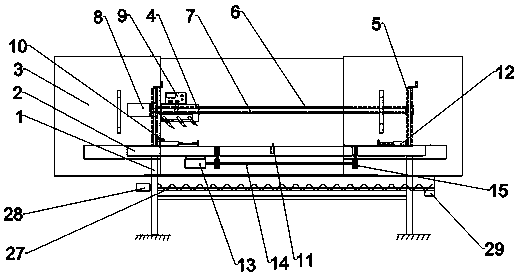

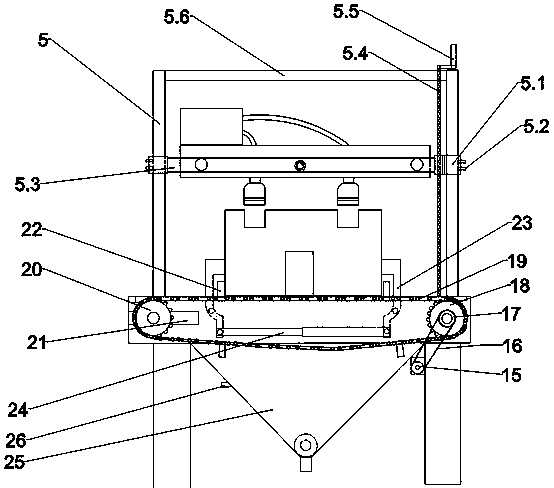

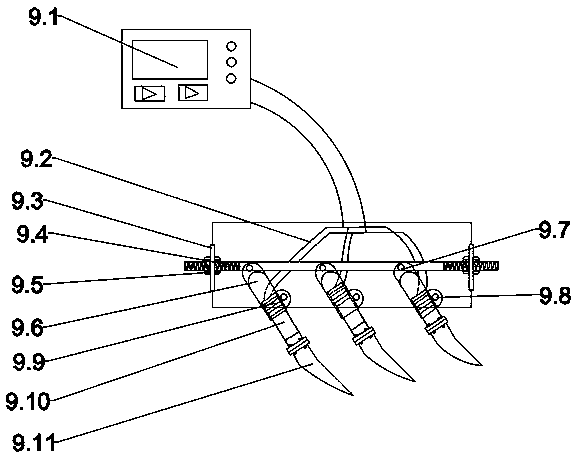

[0036] As shown in the accompanying drawings of the description, an anode carbon block slotting equipment is characterized in that it includes a frame 1, a fixed working platform 2, a safety soundproof cover 3, a mobile working platform 4 and an ultrasonic eradication device 9; the frame 1 The upper part is provided with a fixed working platform 2; the two ends of the fixed working platform 2 are provided with linear chain guide grooves 2.1, the middle part is provided with a round through hole 2.3, and two square through holes 2.2 are provided at the front and rear; the fixed working platform 2 A photoelectric sensor 10 is provided on the left side, a travel switch 11 is provided at the position of the circular through hole 2.3, and two sets of axial clamping hydraulic cylinders 12 are provided at both ends of the fixed working platform 2; Transmission motor 13, the transmission motor 13 is fixed on the bottom surface of the fixed working platform 2, and the output of the tran...

Embodiment 2

[0042] An anode carbon block slotting equipment, characterized in that it includes a frame 1, a fixed working platform 2, a safety soundproof cover 3, a mobile working platform 4 and an ultrasonic eradication device 9; the upper part of the frame 1 is provided with a fixed working platform 2 , the bottom is provided with an inverted cone-shaped waste recovery bin 25; the upper plane of the two ends of the fixed working platform 2 is provided with a linear chain guide groove 2.1, the middle part is provided with a round through hole 2.3, and two square through holes 2.2 are provided at the front and back; The left side of the fixed working platform 2 is provided with a photoelectric sensor 10, the position of the circular through hole 2.3 is provided with a travel switch 11, and two sets of axial clamping hydraulic cylinders 12 are provided at both ends of the fixed working platform 2; the fixed working platform 2 The lower bottom surface is provided with a transmission motor 13...

Embodiment 3

[0049]An anode carbon block slotting equipment, characterized in that it includes a frame 1, a fixed working platform 2, a safety soundproof cover 3, a mobile working platform 4 and an ultrasonic eradication device 9; the upper part of the frame 1 is provided with a fixed working platform 2 ; The two ends of the fixed working platform 2 are provided with a linear chain guide groove 2.1 on the plane, the middle part is provided with a round through hole 2.3, and two square through holes 2.2 are provided at the front and rear; the left side of the fixed working platform 2 is provided with a photoelectric sensor 10 , the position of the round through hole 2.3 is provided with a travel switch 11, two sets of axial clamping hydraulic cylinders 12 are provided at both ends of the fixed working platform 2; a transmission motor 13 is provided on the bottom surface of the fixed working platform 2, and the The motor 13 is fixed on the bottom surface of the fixed working platform 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com