Preparation method of ceramic water reducing agent

A ceramic water-reducing agent and a modification technology are applied in the field of ceramic water-reducing agent and its preparation, and can solve the problems that the performance stability needs to be further improved, the cost of organic small-molecule water-reducing agent is high, and the cost of high-molecular ceramic water-reducing agent is high. , to achieve low dependence on reaction equipment, significant water reduction and dispersion effects, and good chemical and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

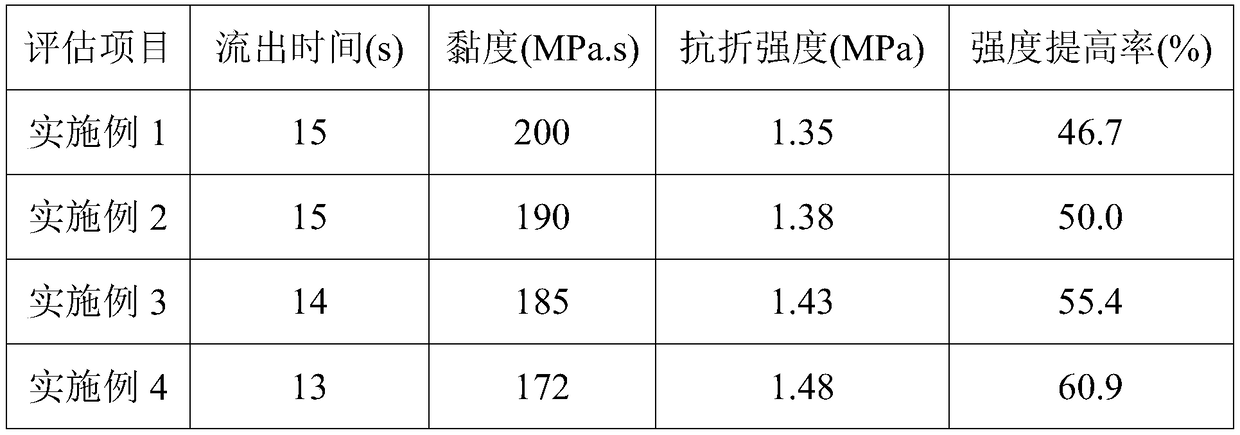

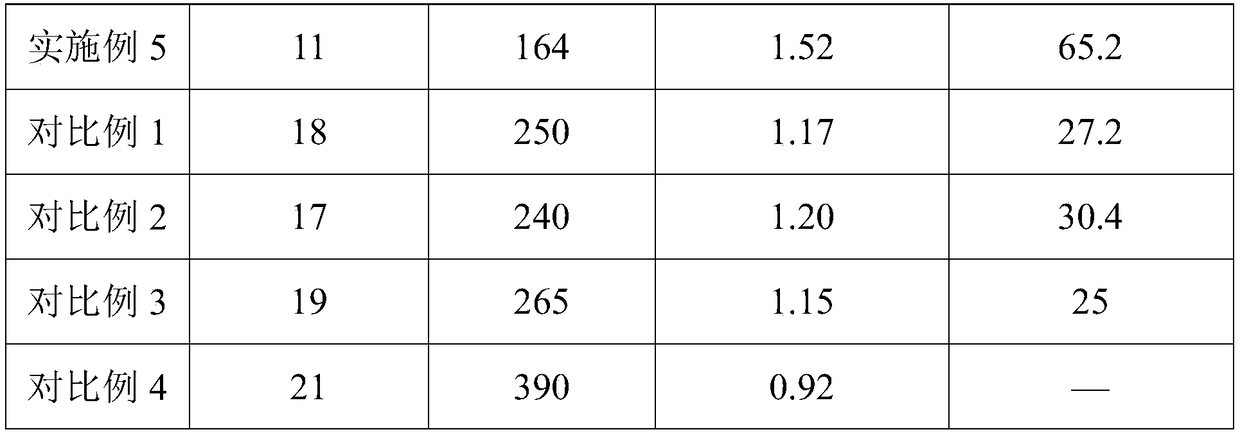

Examples

Embodiment 1

[0038] A preparation method of a ceramic water reducer, comprising the steps of:

[0039] ⅠN-[β-(N,N-diacetoxy)aminoethyl]-γ-(N-acetoxy)aminopropyltrimethoxysilane modified polyethylene glycol monoallyl ether: equipped with stirring Add N-[β-(N,N-diacetoxy)aminoethyl]-γ-(N-acetoxy)aminopropyltrimethoxysilane 6g , polyethylene glycol monoallyl ether 25g, chloranil 0.5g, isopropanol 100g and dibutyltin dilaurate 3g, raise the temperature to 80°C, then add 2g of distilled water dropwise, and stir the reaction at 95°C After 15 hours, it was precipitated in ether, and the precipitated product was washed 3 times with isopentane, and then the solvent was removed by rotary evaporation to obtain N-[β-(N,N-diacetoxy)aminoethyl]-γ-(N -Acetoxy)aminopropyltrimethoxysilane modified polyethylene glycol monoallyl ether;

[0040] II Preparation of quaternary ammonium salt 15 polymeric monomers based on 1-(2-(4-aminophenyl) ethyl) amino-1-(hexaglucosyl) deoxysorbitol: 1-(2-( 5.1 g of 4-amino...

Embodiment 2

[0046] A preparation method of a ceramic water reducer, comprising the steps of:

[0047] ⅠN-[β-(N,N-diacetoxy)aminoethyl]-γ-(N-acetoxy)aminopropyltrimethoxysilane modified polyethylene glycol monoallyl ether: equipped with stirring Add N-[β-(N,N-diacetoxy)aminoethyl]-γ-(N-acetoxy)aminopropyltrimethoxysilane 6g , 28g of polyethylene glycol monoallyl ether, 0.5g of l,4-naphthoquinone, 115g of tetrahydrofuran and 3g of dibutyltin dilaurate, raise the temperature to 82°C, add 2g of distilled water dropwise, and stir the reaction at 98°C After 16.5 hours, it was precipitated in ether, and the precipitated product was washed 4 times with isopentane, and the solvent was removed by rotary evaporation to obtain N-[β-(N,N-diacetoxy)aminoethyl]-γ-(N -Acetoxy)aminopropyltrimethoxysilane modified polyethylene glycol monoallyl ether;

[0048] II Preparation of quaternary ammonium salt 15 polymeric monomers based on 1-(2-(4-aminophenyl) ethyl) amino-1-(hexaglucosyl) deoxysorbitol: 1-(2-( ...

Embodiment 3

[0054] A preparation method of a ceramic water reducer, comprising the steps of:

[0055] ⅠN-[β-(N,N-diacetoxy)aminoethyl]-γ-(N-acetoxy)aminopropyltrimethoxysilane modified polyethylene glycol monoallyl ether: equipped with stirring Add N-[β-(N,N-diacetoxy)aminoethyl]-γ-(N-acetoxy)aminopropyltrimethoxysilane 6g , polyethylene glycol monoallyl ether 30g, chloranil 0.5g, ethylene glycol 125g and dibutyltin dilaurate 3g, raise the temperature to 85°C, then add 2g of distilled water dropwise, and stir the reaction at 100°C After 17.5 hours, it was precipitated in ether, and the precipitated product was washed 5 times with isopentane, and then the solvent was removed by rotary evaporation to obtain N-[β-(N,N-diacetoxy)aminoethyl]-γ-(N -Acetoxy)aminopropyltrimethoxysilane modified polyethylene glycol monoallyl ether;

[0056] II Preparation of quaternary ammonium salt 15 polymeric monomers based on 1-(2-(4-aminophenyl) ethyl) amino-1-(hexaglucosyl) deoxysorbitol: 1-(2-( 51 g of 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com