Anti-corrosive waterborne coating and preparation method thereof

A water-based coating, anti-corrosion technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor water resistance and anti-corrosion performance, organic solvent volatilization, etc., to achieve good anti-corrosion, simple steps, The effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

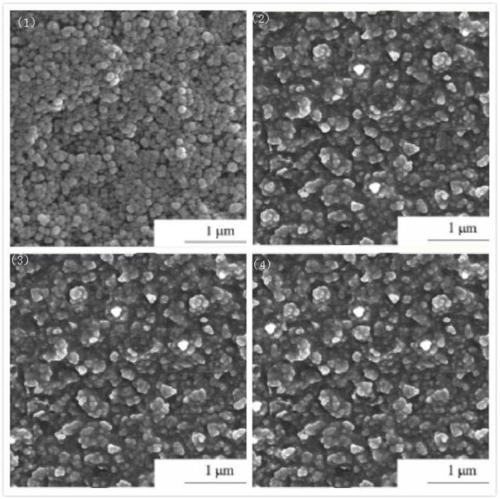

Image

Examples

Embodiment 1

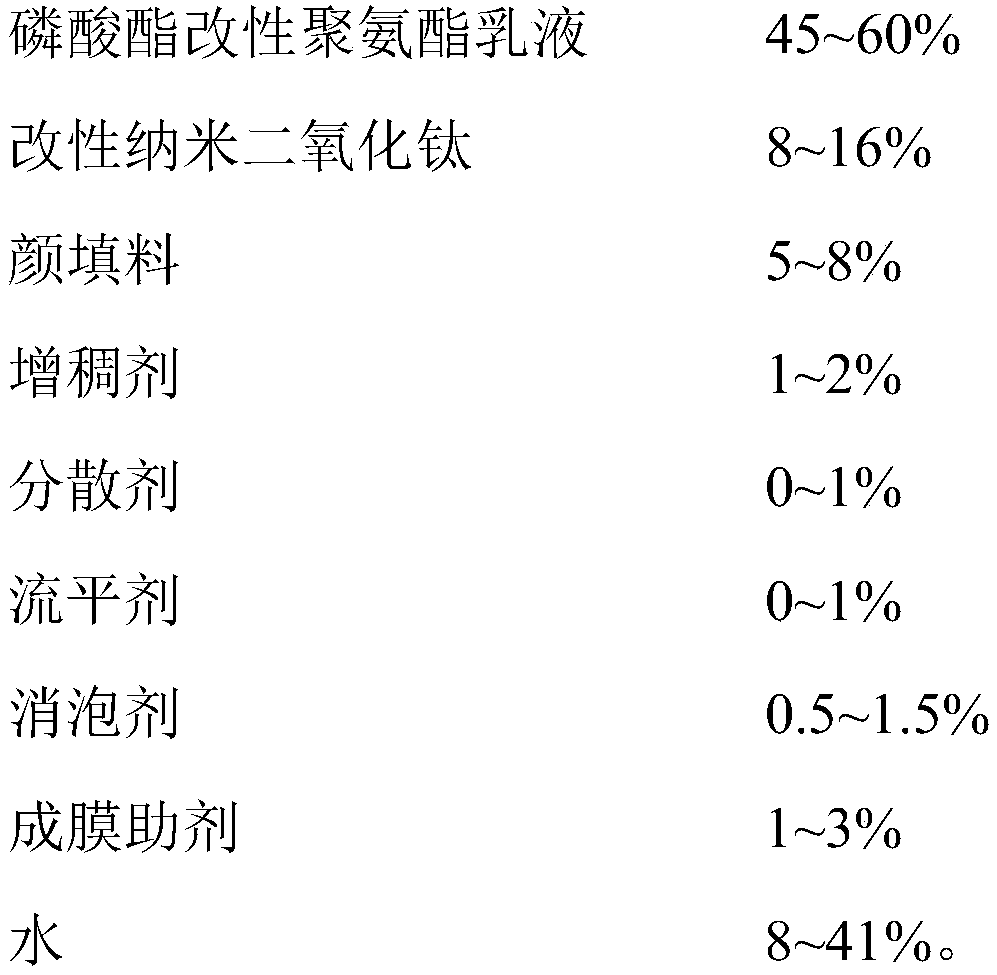

[0025] The present embodiment proposes a kind of anti-corrosion water-based paint, and described anti-corrosion water-based paint comprises the following components by weight percentage:

[0026]

[0027]

[0028] The phosphate-modified polyurethane emulsion includes 5-10% of functional phosphate, 52-69% of polymerized polyol, 20-35% of polyisocyanate, and 0-30% of water;

[0029] The functional phosphate is formed by reacting phosphorus oxide and β-hydroxyethyl methacrylate in a ratio of 1:3.

[0030] The preparation method of the phosphate-modified polyurethane emulsion phosphate-modified polyurethane emulsion is as follows: add the functional phosphate, polymerized polyol, polyisocyanate, and water into the disperser according to the corresponding proportion, and use the rotating speed of 1200-1400r After stirring for 15-40 min, the phosphate-modified polyurethane emulsion was obtained.

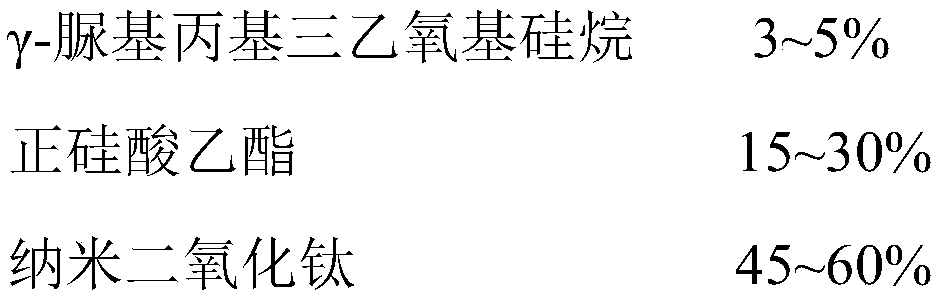

[0031] The modified nano-titanium dioxide comprises the following components: ...

Embodiment 2

[0042] The present embodiment proposes a kind of anti-corrosion water-based paint, and described anti-corrosion water-based paint comprises the following components by weight percentage:

[0043]

[0044] The modified nano-titanium dioxide comprises the following components:

[0045]

[0046] Present embodiment also provides a kind of preparation method of anti-corrosion water-based paint:

[0047] (1) Add the γ-ureidopropyltriethoxysilane into the nano-titanium dioxide, stir for 30 minutes under heating conditions, add the ethyl orthosilicate after the stirring is completed, and continue stirring for 60 minutes.

[0048] (2) Add the functional phosphoric acid ester, polymerized polyol, polyisocyanate ester, and water into the disperser in corresponding proportions, and stir at a rotation speed of 1200 r / min for 15 minutes to obtain the phosphoric acid ester modified polyurethane emulsion.

[0049] (3) Under the condition of stirring, the described phosphate modified po...

Embodiment 3

[0051] The present embodiment proposes a kind of anti-corrosion water-based paint, and described anti-corrosion water-based paint comprises the following components by weight percentage:

[0052]

[0053] The modified nano-titanium dioxide comprises the following components:

[0054]

[0055] Present embodiment also provides a kind of preparation method of anti-corrosion water-based paint:

[0056] (1) Add the γ-ureidopropyltriethoxysilane into the nano-titanium dioxide, stir for 50 minutes under heating conditions, add the ethyl orthosilicate after the stirring is completed, and continue stirring for 80 minutes.

[0057] (2) Add the functional phosphoric acid ester, polymerized polyol, polyisocyanate ester, and water into the disperser in corresponding proportions, and stir for 40 min at a rotational speed of 1400 r / min to obtain the phosphoric acid ester modified polyurethane emulsion.

[0058] (3) under the condition of stirring, add the described phosphate ester modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com