Preparation method of leather greasing agent

The technology of a leather fatliquor and a solvent is applied in the field of preparation of the leather fatliquor, which can solve the problem that the fatliquor cannot meet the requirements of tanning processing and the like, and achieves the advantages of improving comprehensive economic benefits, improving oily feeling and improving effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

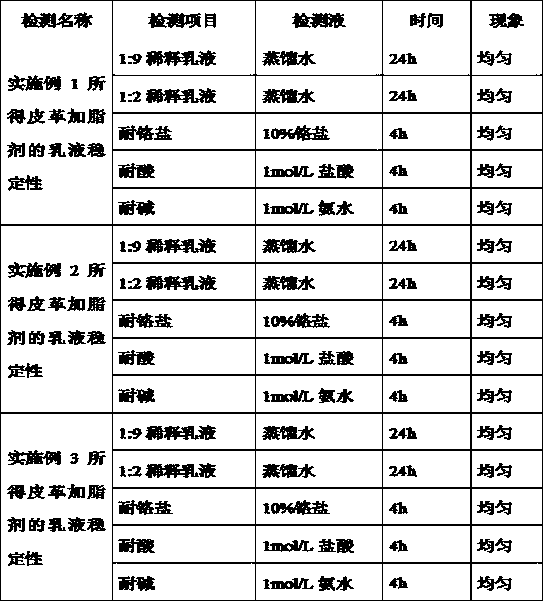

Embodiment 1

[0017] In the enamel reaction kettle, add 200kg sulfonated oil SS, start stirring and raise the temperature to 45°C, stop heating, add 10kg FMES fatty acid methyl ester polyoxyethylene ether sodium sulfonate and 6kg AES fatty alcohol polyoxyethylene ether sodium sulfate, the temperature remains Stir at 45°C for 30 minutes, add 10kg of No. 15 mineral oil, keep the temperature at 45°C, continue to stir for 20 minutes, cool down to 35°C with cooling water, add 3kg of ethylene glycol monobutyl ether, continue to stir for 20 minutes, add 2.0kg of sodium hydroxide The solution (concentration 30%) was adjusted to PH value of 6.0, 0.03kg of Kayson preservative was added, 60kg of deionized water was added, stirred for 30 minutes, and the product leather fatliquor was added. The effective content of the product was 60.2% by extraction method.

Embodiment 2

[0019] In the enamel reaction kettle, add 160kg sulfonated oil FC, start stirring and raise the temperature to 55°C, stop heating, add 6kg FMES sodium fatty acid methyl ester polyoxyethylene ether sulfonate and 3kg AESA fatty alcohol polyoxyethylene ether ammonium sulfate, the temperature Keep stirring at 55°C for 30 minutes, add 12kg of No. 26 mineral oil, keep the temperature at 55°C, continue to stir for 20 minutes, cool down to 35°C with cooling water, add 4kg of diethylene glycol monobutyl ether, continue to stir for 20 minutes, add 3kg of hydroxide Sodium solution (concentration 30%) to adjust the pH value to 6.5, add 0.03kg Kaisong preservative, add 46.6kg deionized water, stir for 30 minutes, add the product leather fatliquoring agent, and the effective content of the product is 60.8% by extraction method .

Embodiment 3

[0021] In the enamel reaction kettle, add 100kg sulfonated oil SS and 120kg sulfonated oil RS-II, start stirring and raise the temperature to 65°C, stop heating, add 12kg FMES sodium fatty acid methyl ester polyoxyethylene ether sulfonate and 7kg AES fatty alcohol poly After sodium oxyethylene ether sulfate, keep the temperature at 65°C and stir for 60 minutes, add 14kg of No. 32 mechanical oil, keep the temperature at 65°C, continue stirring for 30 minutes, cool the cooling water to 35°C, add 5kg of diethylene glycol monobutyl ether, continue Stir for 20 minutes, add 3.5kg of sodium hydroxide solution (concentration 30%) to adjust the pH value to 7.0, add 0.03kg of Kaisong preservative, add 62.5kg of deionized water, stir for 30 minutes, add the product leather fatliquoring agent, after The effective content of the product detected by the extraction method is 61.2%.

[0022] In the above examples, the effective content of the product is the content of sulfonated oil, mineral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com