Method for directionally separating out palladium from silver nitrate mixing solution containing palladium

A technology of directional separation and silver nitrate, applied in the field of wastewater treatment, can solve the problems of high metal co-precipitation rate, easy damage to the nitric acid system, poor separation effect of palladium, etc., and achieve the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

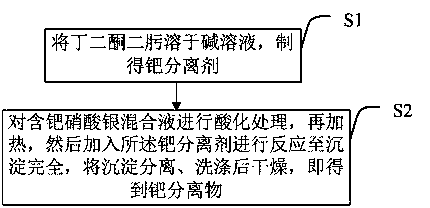

Method used

Image

Examples

Embodiment 1

[0033] A batch of palladium-containing silver nitrate mixed solution A was produced in a comprehensive recovery process of copper anode slime in a copper smelter, in which the concentration of nitric acid was 10.3g / L, the palladium content was 0.36g / L, the silver content was 248g / L, and the copper content was 24.83 g / L, containing bismuth 0.048g / L, containing platinum 0.074g / L, containing gold 0.005g / L, containing selenium 0.001g / L, containing 0.001g / L tellurium.

[0034] Configure palladium separating agent: weigh and analyze 150g of sodium hydroxide and 1L of water to prepare a sodium hydroxide solution with a mass concentration of 15%, then add 50g of diacetyldioxime to it, and fully stir until completely dissolved;

[0035] Take 50L of palladium-containing silver nitrate mixed solution A, transfer it to a reaction kettle and heat it to 60°C with a steam jacket, and keep the temperature constant. Mix well, then slowly add 360 mL of palladium separating agent, stir for 3 hou...

Embodiment 2

[0038]A batch of palladium-containing silver nitrate mixed solution B was produced in the comprehensive recovery process of copper anode slime in a copper smelter, in which the concentration of nitric acid was 8.4g / L, the palladium content was 0.15g / L, the silver content was 198g / L, and the copper content was 20.4 g / L, containing bismuth 0.05g / L, containing platinum 0.044g / L, containing gold 0.005g / L, containing selenium 0.001g / L, containing 0.001g / L tellurium.

[0039] Configure palladium separating agent: weigh and analyze 150g of sodium hydroxide and 1L of water to prepare a sodium hydroxide solution with a mass concentration of 15%, then add 50g of diacetyldioxime to it, and fully stir until completely dissolved;

[0040] Take 45L of palladium-containing silver nitrate mixed solution B, transfer it to a reaction kettle, heat it to 50°C with a steam jacket, and keep the temperature constant, then add 1.8L of reagent nitric acid to the palladium-containing silver nitrate mixe...

Embodiment 3

[0043] A batch of palladium-containing silver nitrate mixed solution C was produced in the comprehensive recovery process of copper anode slime in a copper smelter, in which the concentration of nitric acid was 9.2g / L, the palladium content was 0.22g / L, the silver content was 210g / L, and the copper content was 21.3 g / L, containing bismuth 0.06g / L, containing platinum 0.082g / L, containing gold 0.005g / L, containing selenium 0.001g / L, containing 0.001g / L tellurium.

[0044] Configure palladium separating agent: weigh and analyze 150g of sodium hydroxide and 1L of water to prepare a sodium hydroxide solution with a mass concentration of 10%, then add 60g of diacetyldioxime to it, and stir until completely dissolved;

[0045] Take 60L of palladium-containing silver nitrate mixed solution C, transfer it to a reaction kettle, heat it to 60°C with a steam jacket, and keep the temperature constant, then add 3.6L of reagent nitric acid to the palladium-containing silver nitrate mixed sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com