Zinc-nickel alloy trivalent chromium black passivator and preparation process thereof

A zinc-nickel alloy and a preparation process technology, applied in the field of electrochemical deposition, can solve problems such as increasing production costs, environmental pollution, white rust, etc., and achieve the effects of increasing stability, good corrosion resistance, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

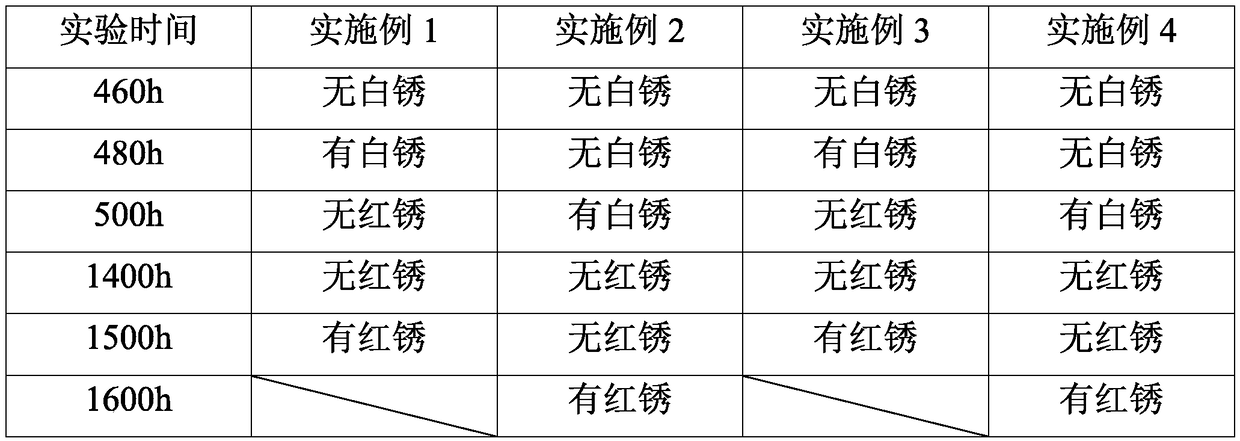

Examples

Embodiment 1

[0039] Weigh 8g of chromium hydroxide, 0.5g of polyethylene oxide and 50ml of water, mix, heat to 90°C, keep stirring for 0.5h, after the heat preservation is completed, let it stand and cool down to 20°C to obtain a trivalent chromium compound solution, and weigh 0.5g of lemon Disodium hydrogen citrate and 21ml of water were mixed and stirred until the sodium hydroxide was completely dissolved to obtain a disodium hydrogen citrate solution. The disodium hydrogen citrate solution was added dropwise to the trivalent chromium compound solution and stirred. After the addition was completed, Supplement 20ml of water to get A agent;

[0040] Weigh 0.5g of glycerol ether, 10g of glacial acetic acid and 86.5ml of water, mix and dissolve to obtain Agent B;

[0041] Control the temperature of 10ml of agent A, 5ml of agent B and 1000ml of water prepared in this example at 30°C, mix and stir for 5 minutes, let stand for 2 hours, adjust the pH to 2, and passivate the zinc-nickel alloy. Th...

Embodiment 2

[0043] Weigh 9g of chromium chloride, 1g of polyethylene oxide and 40ml of water, mix them, heat to 95°C, heat and stir for 45min, after the heat preservation is completed, let stand and cool down to 25°C to obtain a trivalent chromium compound solution, weigh 1g of hydrogen citrate Sodium and 25ml of water, mixed and stirred, stirred until the sodium hydroxide was completely dissolved to obtain a disodium hydrogen citrate solution, and the disodium hydrogen citrate solution was added dropwise to the trivalent chromium compound solution and stirred, after the addition was completed, 24ml of water to obtain agent A;

[0044] Weigh 1g of glycerol ether, 12g of glacial acetic acid and 87ml of water, mix and stir to dissolve to obtain agent B;

[0045] Control the temperature of 15ml of agent A, 7ml of agent B and 1000ml of water prepared in this example at 35°C, mix and stir for 10 minutes, let it stand for 3 hours, adjust the pH to 2, and passivate the zinc-nickel alloy. The pas...

Embodiment 3

[0047] Weigh 10g of chromium sulfate, 1.5g of polyethylene oxide and 40ml of water, mix them, heat to 100°C, heat and stir for 1h, after the heat preservation is completed, let stand and cool down to 30°C to obtain a trivalent chromium compound solution, weigh 2g of hydrogen citrate Sodium and 26.5ml of water, mix and stir until the sodium hydroxide is completely dissolved to obtain a disodium hydrogen citrate solution, add the disodium hydrogen citrate solution dropwise to the trivalent chromium compound solution and stir, after the addition is complete, add 20ml of water to obtain agent A;

[0048] Weigh 2g of glycerol ether, 14g of glacial acetic acid and 84ml of water, mix and stir to dissolve to obtain agent B;

[0049] Control the temperature of 20ml of agent A, 10ml of agent B and 1000ml of water prepared in this example at 40°C, mix and stir for 5 minutes, let it stand for 2 hours, adjust the pH to 2, and passivate the zinc-nickel alloy. The passivation time is 35 seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com