A curved array electrospinning nozzle with sheath gas confinement

An arc-shaped array and electrospinning technology, which is applied in the field of electrospinning, can solve the problems of continuous and stable injection of jets, and achieve the effects of improving injection stability, reducing diameter, and improving injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

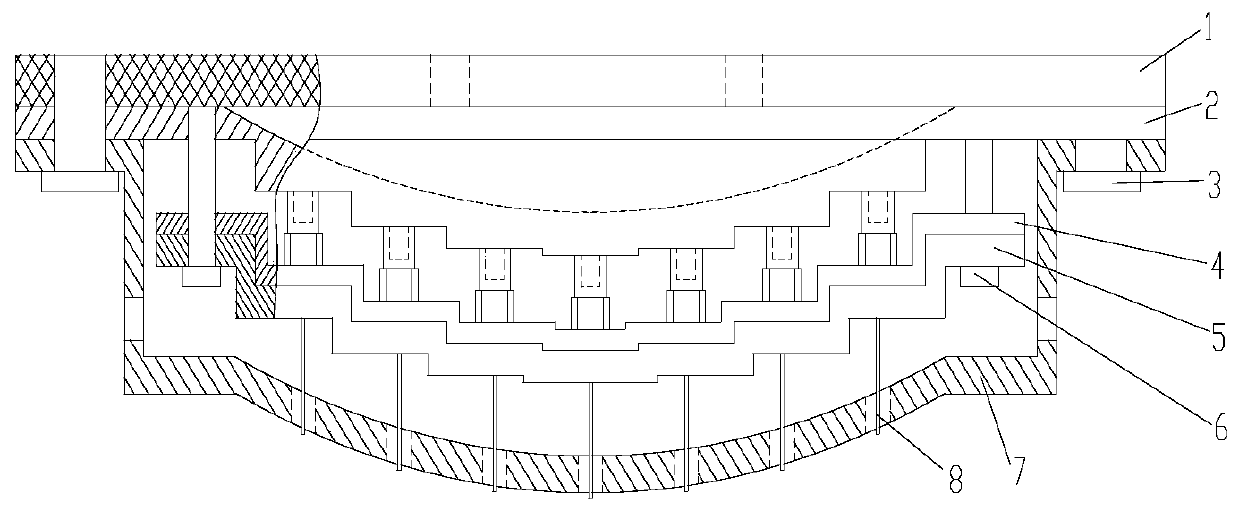

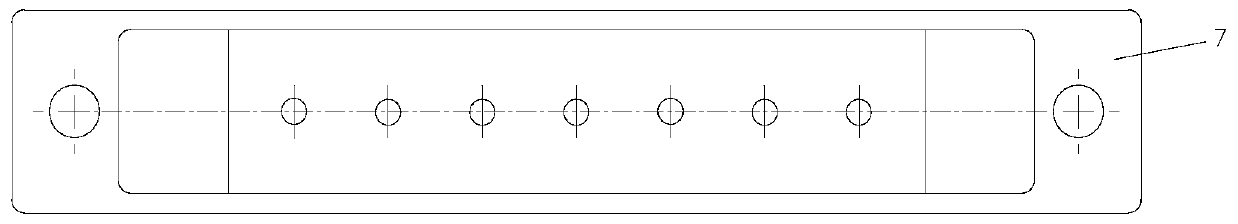

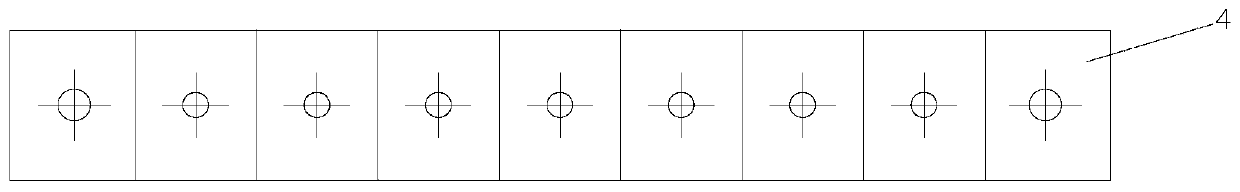

[0027] Such as figure 1 Shown is a specific embodiment of the present invention, which is provided with an upper cover plate 1, a needle mounting plate 2, an outer locking screw 3, a conductive plate 4, a support plate 5, an inner locking screw 6, a gas shield 7 and a needle array 8 . The needle mounting plate 2 is provided with threaded holes, and the needle mounting plate 2 , the conductive plate 4 and the support plate 5 are fixedly connected by inner locking screws 6 . The upper cover 1 is provided with threaded holes, and the upper cover 1 , the needle mounting plate 2 and the gas cover 7 are fixedly connected by external locking screws 3 . Needle array 8 is composed of 7 stainless steel dispensing needles arranged in an arc-shaped array. The height difference between the outermost needle and the middle needle is 12cm, and the needle spa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com