Renewable Antibacterial Fabric and Its Green Preparation Technology

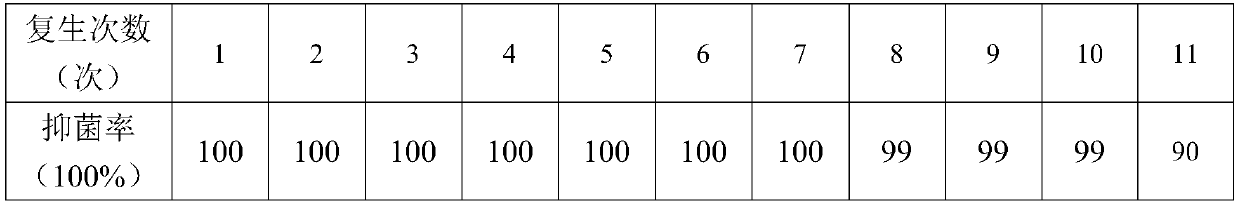

An antibacterial fabric and a preparation process technology are applied in the field of regenerable antibacterial fabric and its green preparation technology, which can solve the problems of complicated preparation method, unsatisfactory washing stability of antibacterial fabric, etc., so as to reduce cross infection and inhibit mites and bacteria. The effect of breeding and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

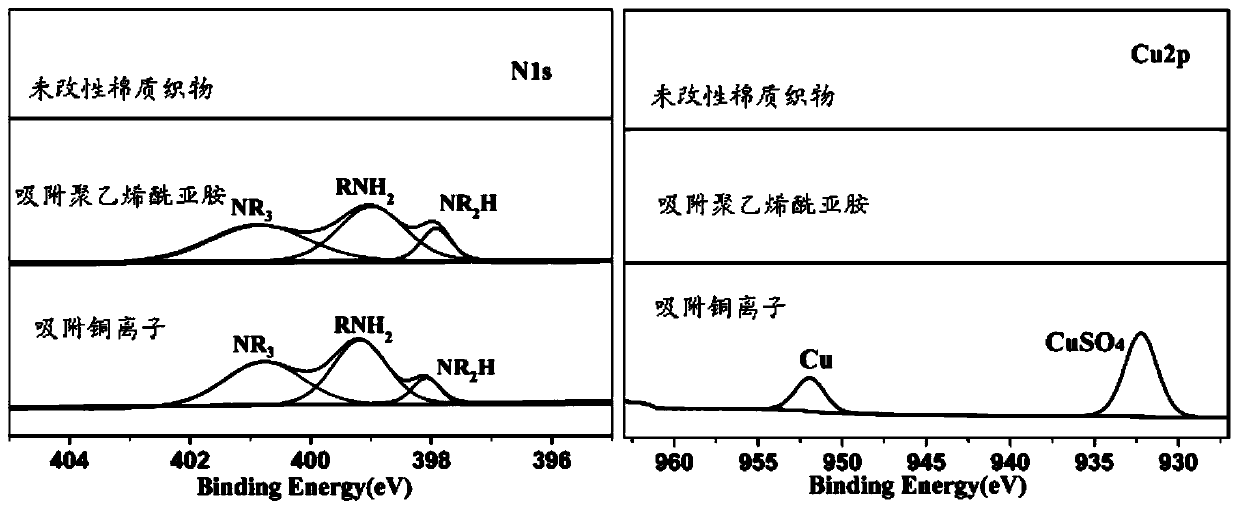

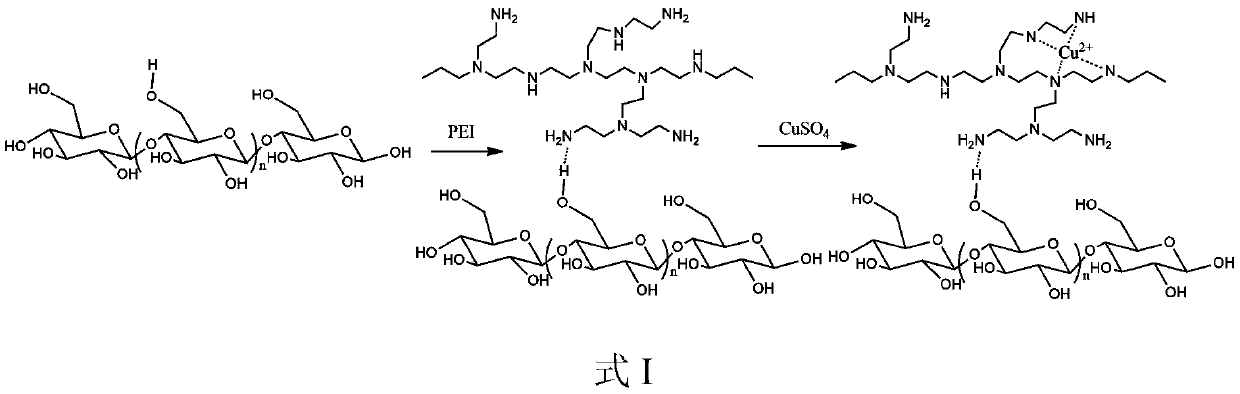

Embodiment 1

[0043] A green preparation process for regenerating antibacterial fabrics includes the following specific preparation process: first, pure cotton fabrics are immersed in a sodium hydroxide solution with a concentration of 1 moL / L, and activated at room temperature for 20 to 40 minutes to obtain surface activation treatment Then take it out, wash it for at least 3 times, then immerse it in an aqueous solution of polyethyleneimine with a concentration of 1.5g / L, and treat it at room temperature for 30-60min to obtain a surface-loaded polyethyleneimine fabric. The surface-loaded polyethyleneimine fabric is immersed in a saturated copper nitrate aqueous solution, treated at room temperature for 5-10 minutes for complexation reaction, taken out, washed with water, and dried to prepare a regenerable antibacterial fabric.

Embodiment 2

[0045]A green preparation process for regenerating antibacterial fabrics includes the following specific preparation process: firstly, the regenerated fibers are immersed in a sodium hydroxide solution with a concentration of 1.2 moL / L, and activated at room temperature for 20 to 40 minutes to obtain a surface activation treatment Then take it out, wash it for at least 3 times, then immerse it in an aqueous solution of polyethyleneimine with a concentration of 1.6 g / L, and treat it at room temperature for 30 to 60 minutes to obtain a fabric loaded with polyethyleneimine on the surface. The surface-loaded polyethyleneimine fabric is immersed in a saturated copper nitrate aqueous solution, treated at room temperature for 5-10 minutes for complexation reaction, taken out, washed with water, and dried to prepare a regenerable antibacterial fabric.

Embodiment 3

[0047] A green preparation process for regenerating antibacterial fabrics includes the following specific preparation process: firstly, immersing nylon fabrics in a sodium hydroxide solution with a concentration of 1.4 moL / L, and performing activation treatment at room temperature for 20-40 minutes to obtain surface activation treatment Then take out and wash the fabric for at least 3 times, then immerse it in a polyethyleneimine aqueous solution with a concentration of 1.7g / L, and treat it at room temperature for 30-60min to obtain a surface-loaded polyethyleneimine fabric. The surface-loaded polyethyleneimine fabric is immersed in a saturated copper nitrate aqueous solution, treated at room temperature for 5-10 minutes for complexation reaction, taken out, washed with water, and dried to prepare a regenerable antibacterial fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com