A method for producing propylene by catalytic reaction of naphtha or light hydrocarbons at low temperature and co-producing aromatics

A low-temperature catalytic and naphtha technology, which is applied in the direction of hydrocarbon cracking to produce hydrocarbons, naphtha treatment, petroleum industry, etc., to achieve the effect of strong operability and increased yield

Active Publication Date: 2020-11-27

北京惠尔三吉绿色化学科技有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There is no specific example for this method, but computer simulations show that under the premise of non-catalytic reforming, this method can achieve a propylene yield of 50.38% and a triphenyl yield of 16%.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0048] This example uses experimental data to illustrate the implementation effect of a process method that uses naphtha or light hydrocarbons as raw materials for low-temperature catalytic reaction to produce propylene and co-produce aromatics.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

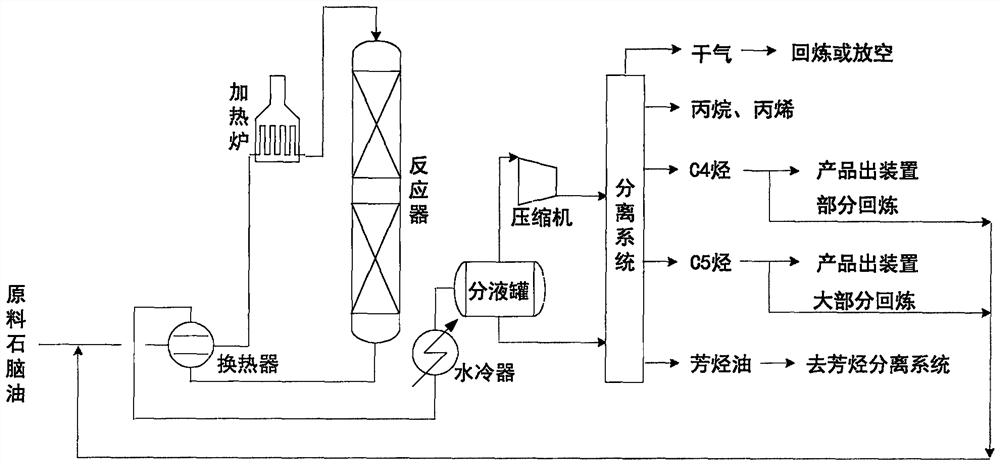

The invention relates to a process method for preparing propene and coproducing aromatic hydrocarbons through low-temperature catalyzed reaction of naphtha or light hydrocarbons as feedstocks. The method comprises the steps: subjecting feedstock naphtha or light hydrocarbons to heat exchange by a heat exchanger and / or heating by a heater, then, enabling the feedstocks to enter a fixed-bed reactor,carrying out a low-temperature catalyzed reaction in the presence of a specific catalyst, and enabling reaction products to pass through a separation system, so as to obtain aromatic hydrocarbons such as ethene, propene, C4-5 hydrocarbons and byproducts, i.e., toluene and xylene, wherein one part of the C4-5 hydrocarbons circulate back to the reactor. According to the process method, the reactionis carried out in the fixed-bed reactor, and a catalyzed reaction temperature is lower than that of the traditional naphtha catalyzed cracking process and is far lower than that of the traditional naphtha steam cracking process; a self-produced C4-5 hydrocarbon recirculating mode is adopted, and reaction heat is fully utilized; and the method is adjustable in product distribution, and relativelyhigh yield of propene and aromatic hydrocarbons can be simultaneously obtained.

Description

technical field [0001] The invention relates to a process method for producing propylene and producing aromatic hydrocarbons by using naphtha or light hydrocarbons as raw materials through low-temperature catalytic reaction. Specifically, in a fixed-bed reactor, under the action of a lower reaction temperature and a characteristic catalyst, naphtha or light hydrocarbons are cracked to generate high-yield propylene products and co-produce aromatics. Background technique [0002] Propylene is one of the most basic and important raw materials in the modern petrochemical industry. In recent years, the global demand for propylene is growing rapidly, and at the same time, non-renewable petroleum resources are becoming increasingly scarce. At present, about 60% of propylene comes from traditional naphtha steam thermal cracking technology, but traditional naphtha steam thermal cracking technology not only has high reaction temperature, high energy consumption, but also low propylen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10G55/06C10G61/02C07C4/06C07C11/06

CPCC07C4/06C10G55/06C10G61/02C10G2300/1037C10G2300/1044C10G2300/4006C10G2300/4012C10G2400/30C07C11/06Y02P20/52

Inventor 龚小燕张丰豪丁艳明张芳孙艳茹郭金宝

Owner 北京惠尔三吉绿色化学科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com