Self-powered sensor used for detecting microcystic toxins

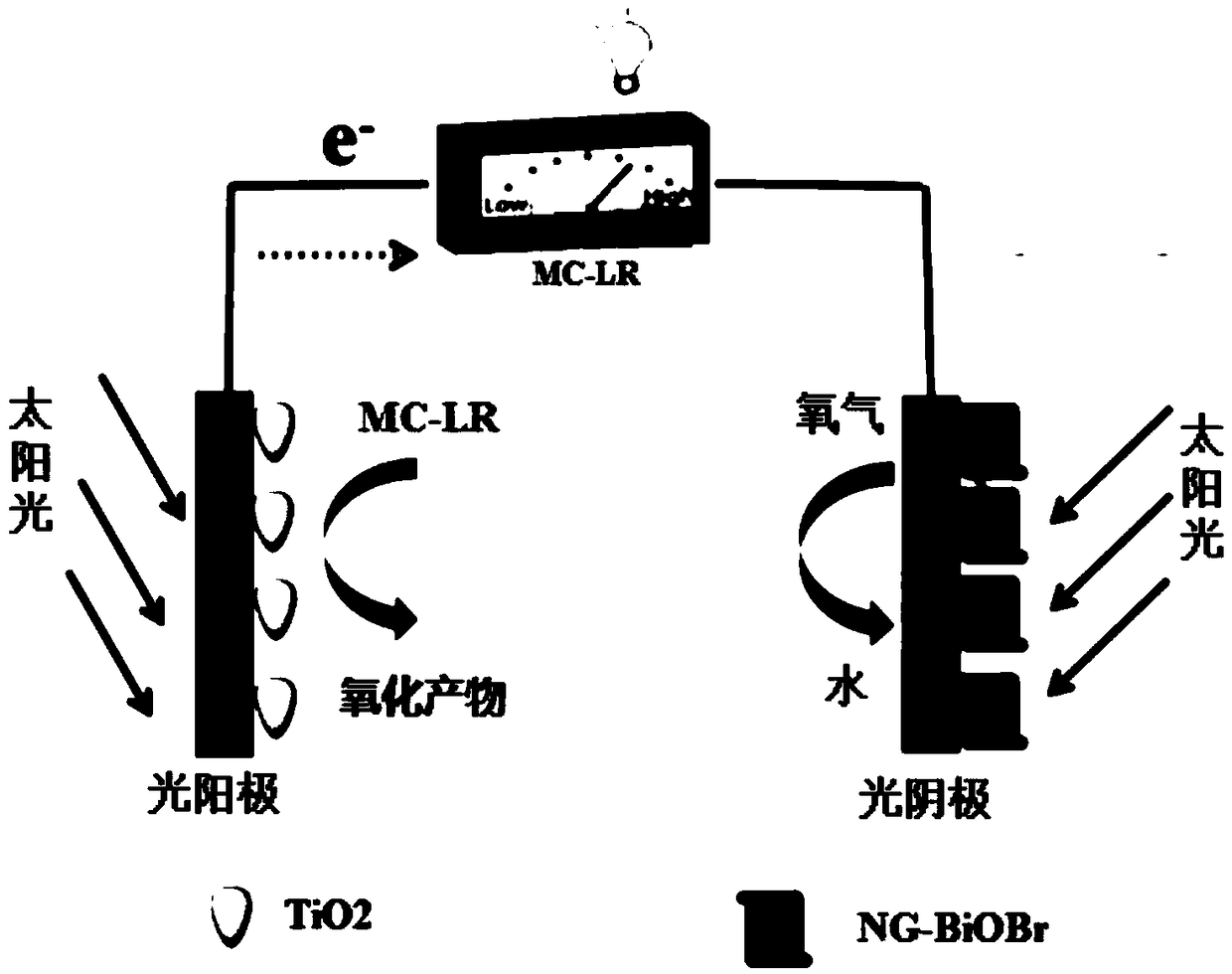

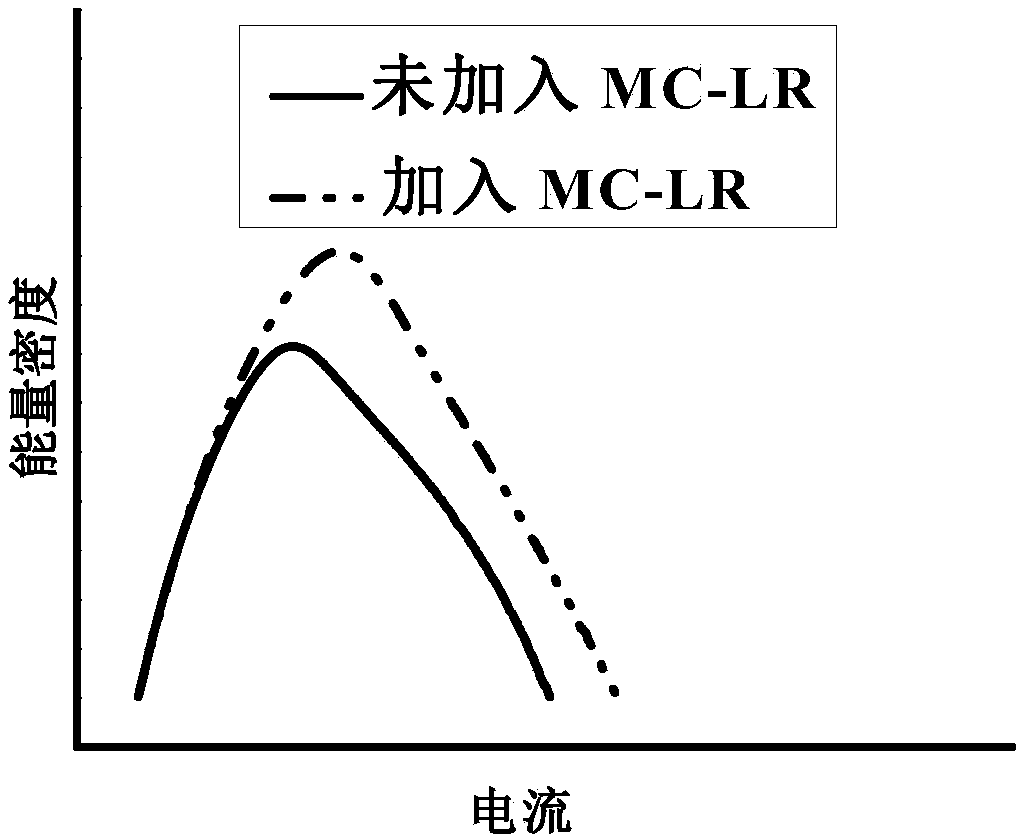

A microcystin and self-powered technology, which is applied in the field of photocatalytic fuel cells and sensors, can solve the problems of high cost, harsh operating conditions, and low energy conversion efficiency of photo-assisted fuel cells, so as to reduce production costs and achieve good results. Application prospect, effect of improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

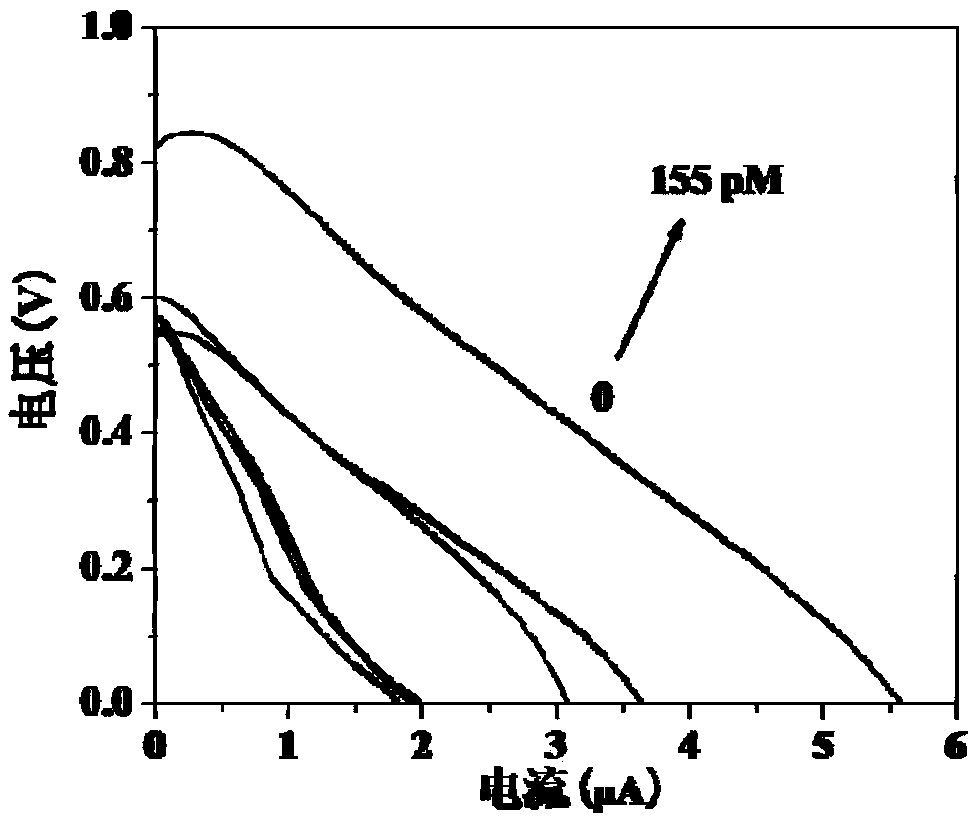

Examples

Embodiment 1

[0024] 1. Preparation of Photoelectrodes

[0025] (1) Preparation of photoanode: First, 4mL [TiO(C 4 h 9 O) 4 ] dissolved in 20mL 6mol / L of HNO 3 TiO(NO 3 ) 2 solution, and then the TiO(NO 3 ) 2 The solution was transferred to a polytetrafluoroethylene-lined reactor, and reacted at 160°C for 12 hours. After natural cooling, the reaction product was centrifuged, washed with ultrapure water and absolute ethanol, and finally dried at 60°C. , to obtain the photoanode nanomaterial TiO 2 . The powder obtained above was ultrasonically dispersed in N,N-dimethylformamide (DMF) to prepare a 6 mg / mL ultrasonic dispersion. Pipette 20μL of the above dispersion solution and apply it on the effective area of 0.5cm 2 The surface of the ITO electrode was heated and dried under an infrared lamp. At this time, it can be observed that a layer of uniform film structure is naturally formed on the surface of the ITO electrode, and the preparation of the photoanode is completed.

[0026]...

Embodiment 2

[0033] 1. Preparation of Photoelectrodes

[0034] (1) Preparation of photoanode: First, 5mL [TiO(C 4 h 9 O) 4 ] dissolved in 40mL 6mol / L of HNO 3 TiO(NO 3 ) 2 solution, and then the TiO(NO 3 ) 2 The solution was transferred to a polytetrafluoroethylene-lined reaction kettle, reacted at 180°C for 12 hours, and after natural cooling, the reaction product was centrifuged, washed with ultrapure water and absolute ethanol, and finally dried at 60°C , to obtain the photoanode nanomaterial TiO 2 . The powder obtained above was ultrasonically dispersed in DMF to prepare a 6 mg / mL ultrasonic dispersion. Pipette 20μL of the above dispersion solution and apply it on the effective area of 0.5cm 2 The surface of the ITO electrode was heated and dried under an infrared lamp. At this time, it can be observed that a layer of uniform film structure is naturally formed on the surface of the ITO electrode, and the preparation of the photoanode is completed.

[0035] (2) Preparation ...

Embodiment 3

[0041] 1. Preparation of Photoelectrodes

[0042] (1) Preparation of photoanode: First, 5mL TiO(C 4 h 9 O) 4 Dissolved in 50mL 6mol / L HNO 3 TiO(NO 3 ) 2 solution, and then the TiO(NO 3 ) 2 The solution was transferred to a polytetrafluoroethylene-lined reactor, and reacted at 200°C for 12 hours. After natural cooling, the reaction product was centrifuged, washed with ultrapure water and absolute ethanol, and finally dried at 60°C. , to obtain the photoanode nanomaterial TiO 2 . The powder obtained above was ultrasonically dispersed in DMF to prepare a 6 mg / L ultrasonic dispersion. Pipette 20μL of the above dispersion solution and apply it on the effective area of 0.5cm 2 The surface of the ITO electrode was heated and dried under an infrared lamp. At this time, it can be observed that a layer of uniform film structure is naturally formed on the surface of the ITO electrode, and the preparation of the photoanode is completed.

[0043] (2) Preparation of photocathod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com