Beneficiation method for eliminating radioaction of quartz feldspar concentrate

A beneficiation method and radioactive technology are applied in the field of mineral processing for removing the radioactivity of quartz feldspar concentrates, which can solve the problems of ineffective removal of radioactivity, unavailability, hidden dangers of regional environment, etc., so as to improve the comprehensive utilization rate of resources, purity and quality. , reducing the effect of radioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

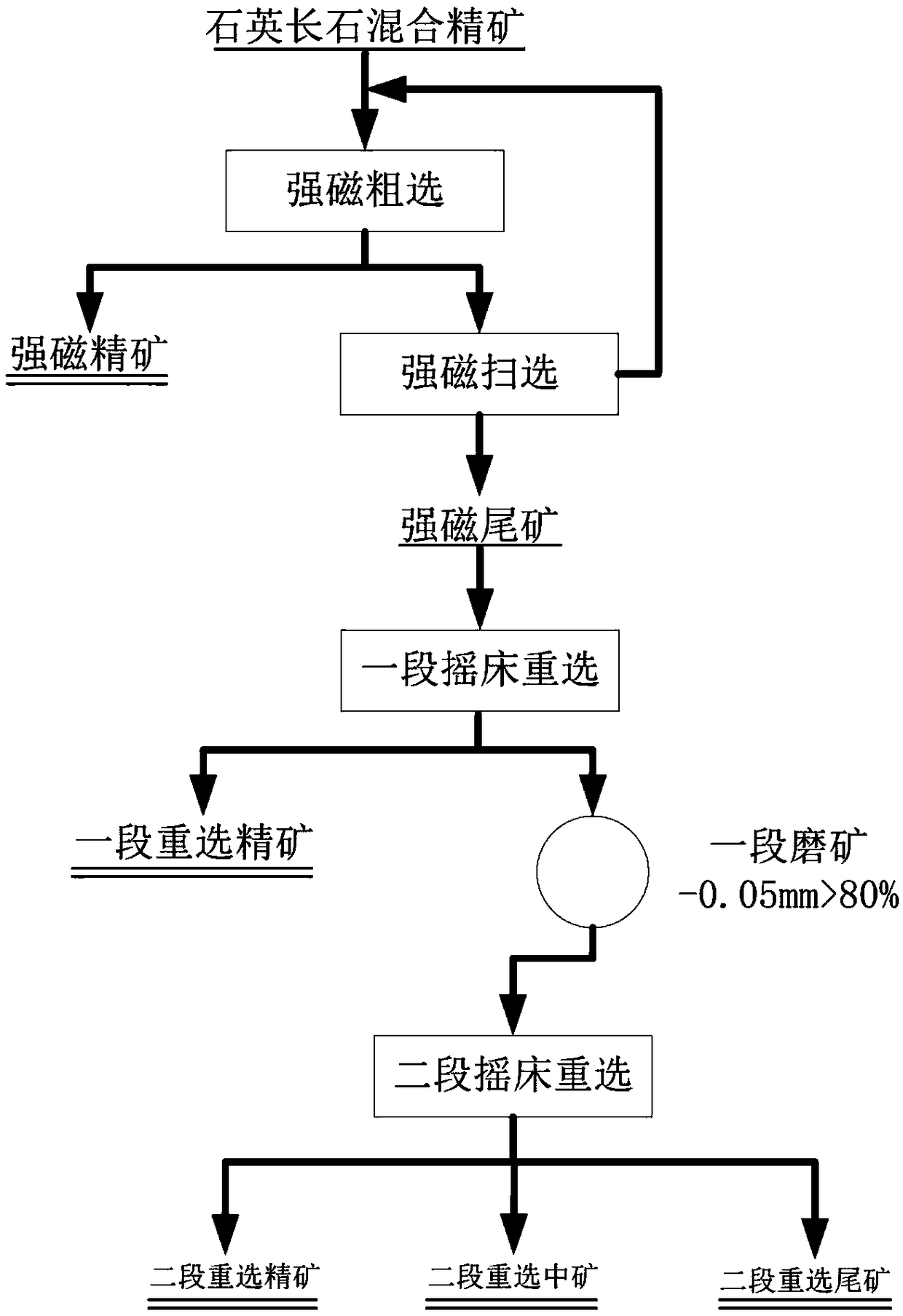

Image

Examples

Embodiment 1

[0029] The total ratio of radioactivity is 8.53×10 3 Bq / kg, internal exposure index I Ra =2.2, external exposure index I r =3.0, particle size-0.1mm accounts for 85%, and the radioactive quartz feldspar mixed concentrate with a purity of 96.30% is used as a raw material. The invention provides a mineral processing method for removing the radioactivity of the quartz feldspar concentrate, which includes the following steps:

[0030] (1) Strong magnetic separation: Grind 1kg of quartz feldspar mixed concentrate with excessive radioactivity, the particle size is -0.1mm>85%, and then mix the fine powder after grinding into pulp with a concentration of 10% for wet processing Strong magnetic separation, the strong magnetic separation includes a closed-circuit process consisting of one roughing and one sweeping. After roughing, a roughing concentrate and a roughing tailings are obtained, and the roughing tailings are subjected to a sweeping to obtain a sweeping Concentrated ore and ...

Embodiment 2

[0034] The total ratio of radioactivity is 7.78×10 3 Bq / kg, internal exposure index I Ra =1.8, external exposure index I r =2.8, particle size-0.1mm accounts for 80%, and the quartz feldspar mixed concentrate with radioactivity exceeding the standard of 94.35% is a raw material. The invention provides a kind of mineral processing method for removing the radioactivity of quartz feldspar concentrate, comprising the following steps:

[0035] (1) Strong magnetic separation: Grind 1kg of quartz feldspar mixed concentrate with excessive radioactivity, the particle size is -0.1mm>80%, and then mix the fine powder after grinding into a pulp with a concentration of 30% for wet processing Strong magnetic separation, the strong magnetic separation includes a closed-circuit process consisting of one roughing and one sweeping. After roughing, a roughing concentrate and a roughing tailings are obtained, and the roughing tailings are subjected to a sweeping to obtain a sweeping Concentrate...

Embodiment 3

[0039] Take the total ratio of radioactivity as 3.55×10 3 Bq / kg, internal exposure index I Ra =1.2, external exposure index I r =1.5, particle size-0.1mm accounts for 87%, and the quartz feldspar mixed concentrate with radioactivity exceeding the standard of 97.25% is a raw material. The invention provides a kind of mineral processing method for removing the radioactivity of quartz feldspar concentrate, comprising the following steps:

[0040] (1) Strong magnetic separation: Grind 1kg of quartz feldspar mixed concentrate with excessive radioactivity, the particle size is -0.1mm>87%, and then mix the fine powder after grinding into a pulp with a concentration of 20% for wet processing Strong magnetic separation, the strong magnetic separation includes a closed-circuit process consisting of one roughing and one sweeping. After roughing, a roughing concentrate and a roughing tailings are obtained, and the roughing tailings are subjected to a sweeping to obtain a sweeping Concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com