Method for microbial degradation of total petroleum hydrocarbons

A technology for microbial degradation and total petroleum hydrocarbons, which is applied in the field of microbial degradation of total petroleum hydrocarbons, can solve the problems of high salinity and reduce the degradation rate of petroleum hydrocarbons by petroleum hydrocarbon degrading bacteria, and achieves the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

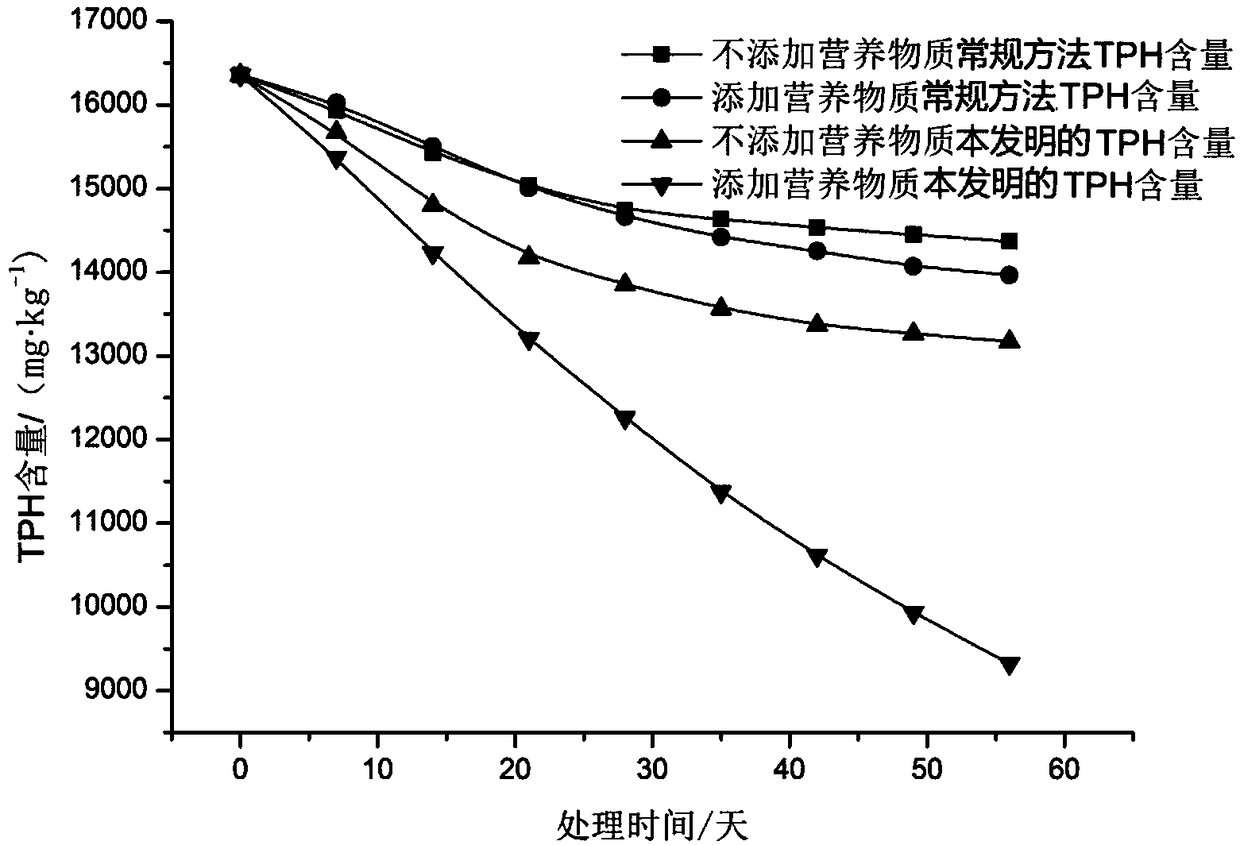

Embodiment 1

[0026] A method for microbial degradation of total petroleum hydrocarbons, comprising the steps of:

[0027] (1) Solid-phase oil-based drilling fluid pretreatment

[0028] The bottom sediment of the waste oil-based drilling fluid is air-dried by a blower to obtain a solid phase sediment, and a pH regulator is added to the solid phase sediment to make the pH value between 6 and 8, and at the same time, the water content does not exceed 10%;

[0029] (2) Add 0.2g of SQ-1 engineering bacteria, 0.1g of SQ-2 engineering bacteria, and 1mL of SQ-3 engineering bacteria to each kilogram of solid-phase sediment in step (1), and then treat them in a warm environment at 24°C 50-60 days, during which the humidity of the solid phase deposit is maintained at 30%-40% by adding water.

Embodiment 2

[0031] A method for microbial degradation of total petroleum hydrocarbons, comprising the steps of:

[0032] (1) Solid-phase oil-based drilling fluid pretreatment

[0033] The bottom sediment of the waste oil-based drilling fluid is air-dried by a blower to obtain a solid phase sediment, and a pH regulator is added to the solid phase sediment to make the pH value between 6 and 8, and at the same time, the water content does not exceed 10%;

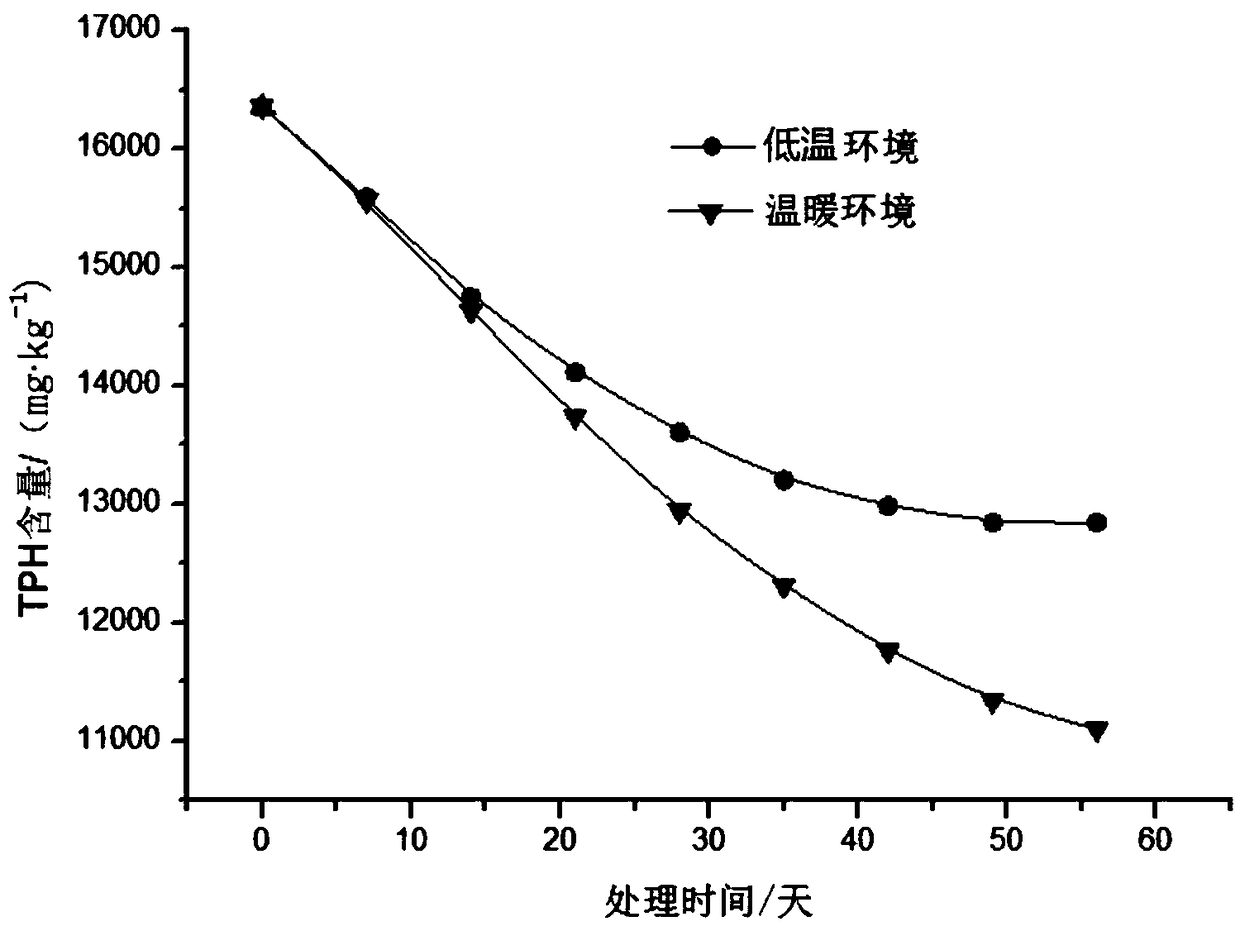

[0034] (2) Add SQ-1 engineering bacterium 0.2g, SQ-2 engineering bacterium 0.1g, SQ-3 engineering bacterium 1mL respectively in the solid phase deposit of every kilogram of step (1), add water to make its humidity reach 20%;

[0035] (3) Add 0.1g NH respectively in every kilogram of solid phase deposit of step (2) 4 NO 3 and 0.1 g KH 2 PO 4 , and then treated in a warm environment at 24°C for 50-60 days, during which the humidity of the solid-phase deposit was maintained at 30%-40% by adding water.

Embodiment 3

[0037] A method for microbial degradation of total petroleum hydrocarbons, comprising the steps of:

[0038] (1) Solid-phase oil-based drilling fluid pretreatment

[0039] The bottom sediment of the waste oil-based drilling fluid is air-dried by a blower to obtain a solid phase sediment, and a pH regulator is added to the solid phase sediment to make the pH value between 6 and 8, and at the same time, the water content does not exceed 10%;

[0040] (2) Add SQ-1 engineering bacterium 0.2g, SQ-2 engineering bacterium 0.1g, SQ-3 engineering bacterium 1mL respectively in the solid phase deposit of every kilogram of step (1), add water to make its humidity reach 20%;

[0041] (3) Add 0.1g NH respectively in every kilogram of solid phase deposit of step (2) 4 NO 3 and 0.1 g KH 2 PO 4, and then treated at a low temperature of 2°C for 50 to 60 days, during which the humidity of the solid phase deposit was maintained at 30% to 40% by adding water.

[0042] In Examples 1 to 3, SQ-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com