Anti-aging anti-drop wear-resistant electronic equipment shell material

A technology for electronic equipment and casing materials, which is applied in the field of aging-resistant, drop-resistant and wear-resistant electronic equipment casing materials, which can solve problems such as low strength, increased casing weight, and poor impact performance, and achieve improved compatibility, improved mechanical strength, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

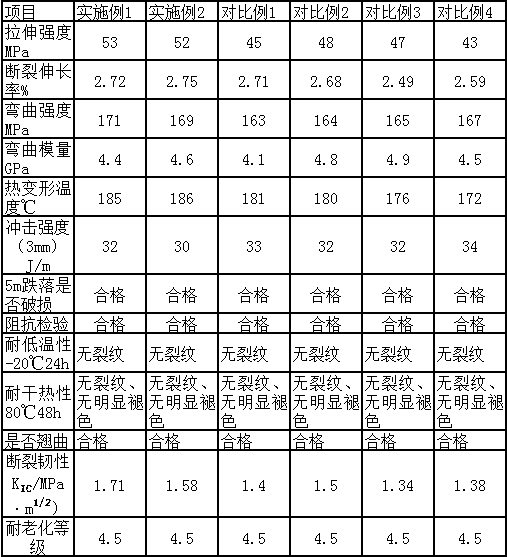

Examples

Embodiment 1

[0023] An aging-resistant, drop-resistant and wear-resistant electronic equipment shell material, mainly prepared from the following raw materials in parts by weight: 120 parts of benzoxazine monomer, 34 parts of modified phenolic resin, 10 parts of α-eucryptite powder, and liquid nitrile 7 parts of rubber, 30 parts of vinyl ester resin, 1-2 parts of stabilizer, 6 parts of magnesium borate whiskers, 3 parts of environmental curing agent, 0.5 parts of release agent, and 0.5 parts of curing accelerator.

[0024] An aging-resistant, drop-resistant and wear-resistant electronic equipment shell material is characterized in that its preparation method comprises the following steps:

[0025] In the first step, each raw material is weighed and mixed evenly;

[0026] Step 2, reaction molding: Inject into the airtight shell mold according to the established processing conditions, produce a rapid processing reaction in the mold and then solidify and form, complete the processing and mold...

Embodiment 2

[0033] An aging-resistant, drop-resistant and wear-resistant electronic equipment casing material, mainly prepared from the following raw materials in parts by weight: 149 parts of benzoxazine monomer, 60 parts of modified phenolic resin, 11 parts of α-eucryptite powder, and liquid nitrile 10 parts of rubber, 45 parts of vinyl ester resin, 2 parts of stabilizer, 6 parts of magnesium borate whiskers, 3 parts of environmental curing agent, 1 part of release agent, and 0.5 parts of curing accelerator.

[0034] An aging-resistant, drop-resistant and wear-resistant electronic equipment shell material is characterized in that its preparation method comprises the following steps:

[0035] In the first step, each raw material is weighed and mixed evenly;

[0036] Step 2, reaction molding: Inject into the airtight shell mold according to the established processing technology conditions, produce a rapid processing reaction in the mold and then solidify and form, complete the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com