Nitride red fluorescent powder used for white light LED, and preparation method thereof

A red fluorescent powder and red fluorescent technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of reducing white light luminous efficiency, low luminous intensity, harmful to human body, etc., to improve luminous intensity, reduce energy consumption and cost, The effect of shortening the reaction sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

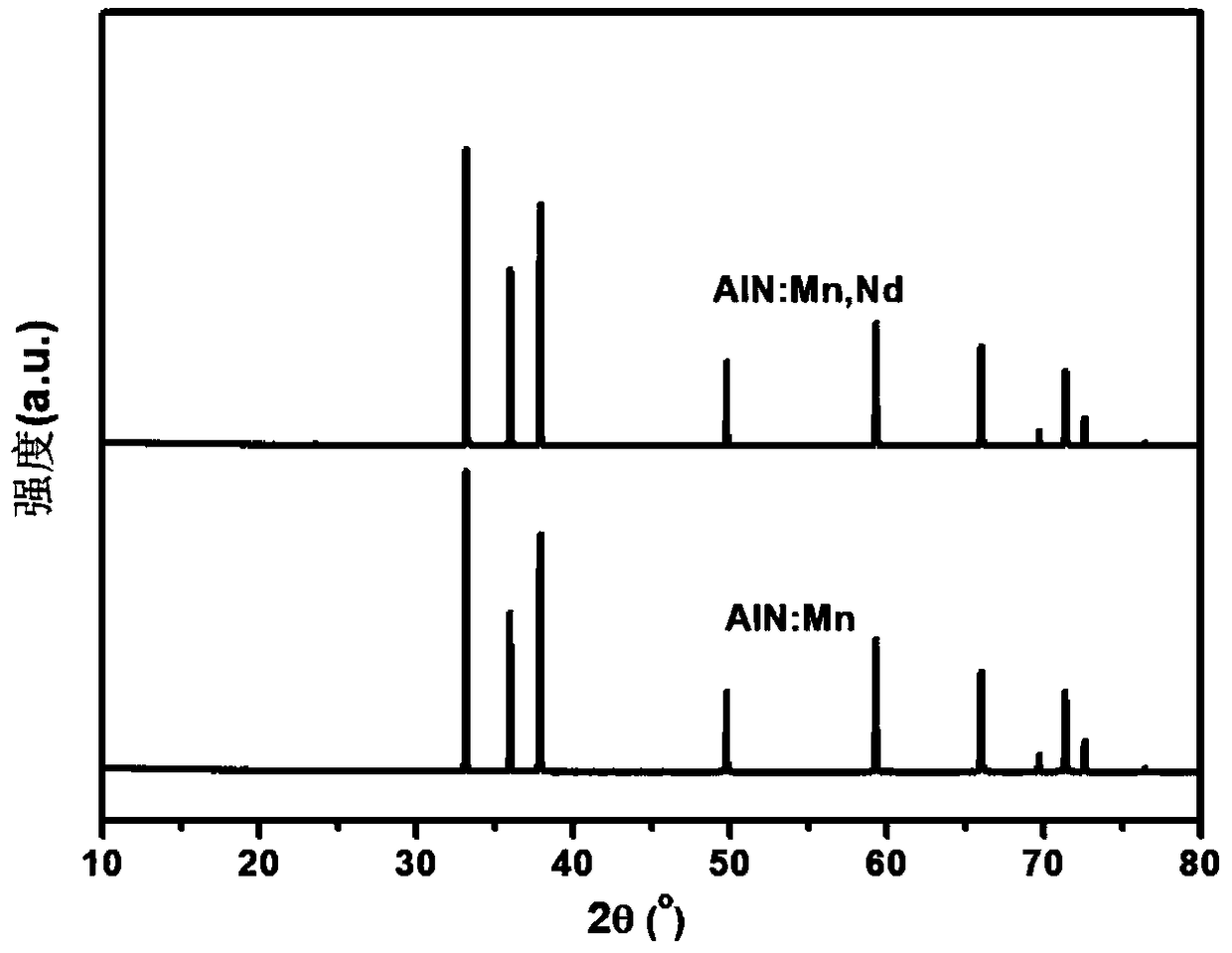

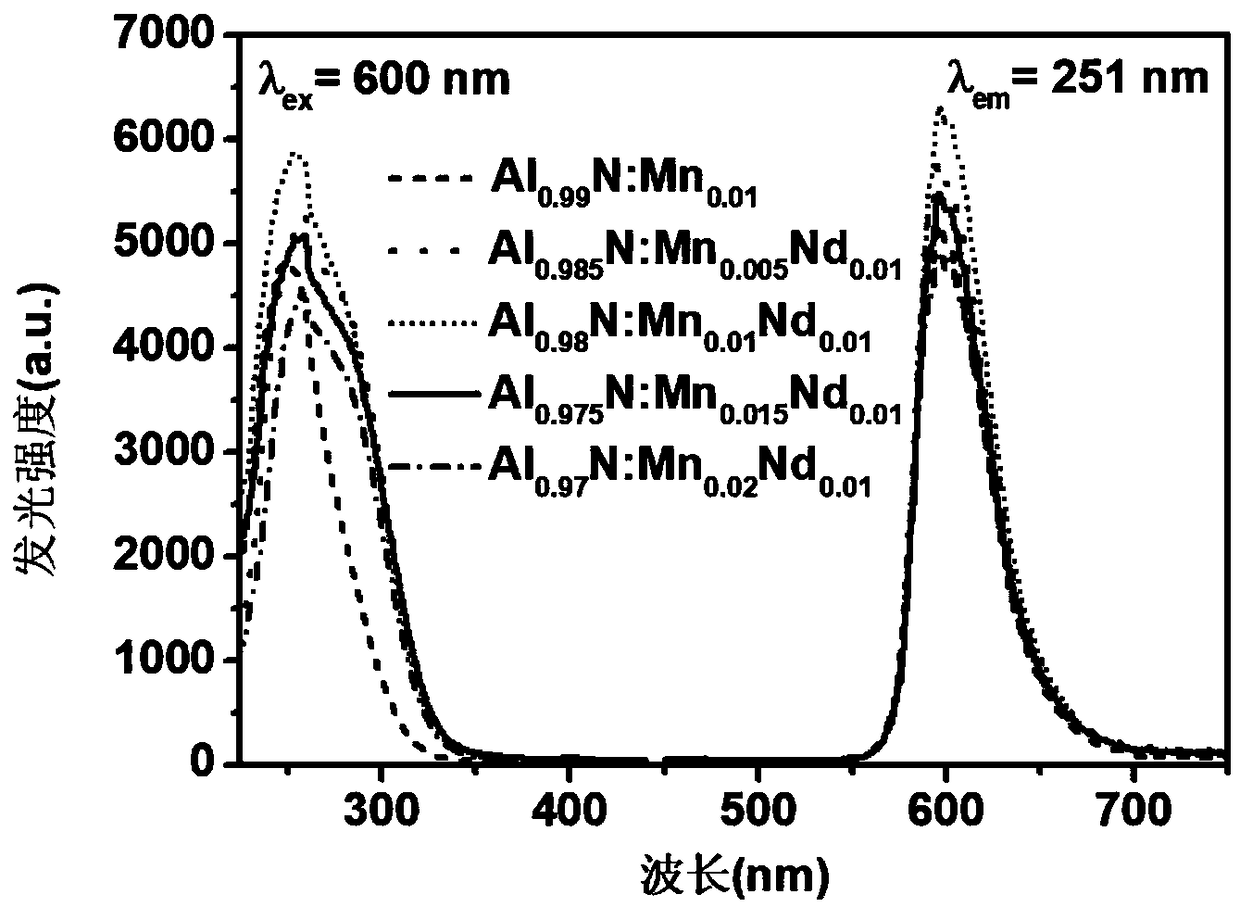

[0025] Embodiment 1: prepare Al 0.985 N:Mn 0.005 ,Nd 0.01

[0026] (1) Set the target product Al 0.985 N:Mn 0.005 ,Nd 0.01 Quality is 2.5g, according to the ratio of the amount of substance of Al:Mn:Nd being 0.985:0.005:0.01, take raw material AlN (99.9%), MnCO 3 (99.9%) and Nd 2 o 3 (99.99%), put into an agate mortar and grind and mix uniformly to obtain a precursor mixture;

[0027] (2) Put the precursor mixture obtained in step (1) into a high-purity boron nitride crucible, then place it in a gas pressure sintering furnace with graphite as a heating element, and sinter in a nitrogen atmosphere at a pressure of 1.0 MPa and a temperature of 1900°C, keep warm for 2 hours, the heating rate is 500°C / h, and the synthesized phosphor is water-cooled with the furnace body;

[0028] (3) Take out the fluorescent powder synthesized in step (2), put it into a beaker filled with deionized water, add concentrated hydrochloric acid with a mass fraction of 36%-38%, wherein the volu...

Embodiment 2

[0029] Embodiment 2: prepare Al 0.98 N:Mn 0.01 ,Nd 0.01

[0030] (1) Set the target product Al 0.98 N:Mn 0.01 ,Nd 0.01 The quality is 2.5g, according to the ratio of the amount of substance of Al:Mn:Nd being 0.98:0.01:0.01, take raw material AlN (99.9%), MnCO 3 (99.9%) and Nd 2 o 3 (99.99%), put into an agate mortar and grind and mix uniformly to obtain a precursor mixture;

[0031] (2) Put the precursor mixture obtained in step (1) into a high-purity boron nitride crucible, then place it in a gas pressure sintering furnace with graphite as a heating element, and sinter in a nitrogen atmosphere at a pressure of 1.0 MPa and a temperature of 1900°C, keep warm for 2 hours, the heating rate is 500°C / h, and the synthesized phosphor is water-cooled with the furnace body;

[0032](3) Take out the fluorescent powder synthesized in step (2), put it into a beaker filled with deionized water, add concentrated hydrochloric acid with a mass fraction of 36%-38%, wherein the volume ...

Embodiment 3

[0033] Embodiment 3: prepare Al 0.975 N:Mn 0.015 ,Nd 0.01

[0034] (1) Set the target product Al 0.975 N:Mn 0.015 ,Nd 0.01 Quality is 2.5g, according to the ratio of the amount of substance of Al:Mn:Nd being 0.975:0.015:0.01, take raw material AlN (99.9%), MnCO 3 (99.9%) and Nd 2 o 3 (99.99%), put into an agate mortar and grind and mix uniformly to obtain a precursor mixture;

[0035] (2) Put the precursor mixture obtained in step (1) into a high-purity boron nitride crucible, then place it in a gas pressure sintering furnace with graphite as a heating element, and sinter in a nitrogen atmosphere at a pressure of 1.0 MPa and a temperature of 1900°C, keep warm for 2 hours, the heating rate is 500°C / h, and the synthesized phosphor is water-cooled with the furnace body;

[0036] (3) Take out the fluorescent powder synthesized in step (2), put it into a beaker filled with deionized water, add concentrated hydrochloric acid with a mass fraction of 36%-38%, wherein the volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com