Recycling process of vanadium in vanadium-containing steel slag

A process and steel slag technology, applied in metallurgy and comprehensive utilization of solid waste, can solve the problems of high recycling cost and low yield, and achieve the effect of reduced recycling cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

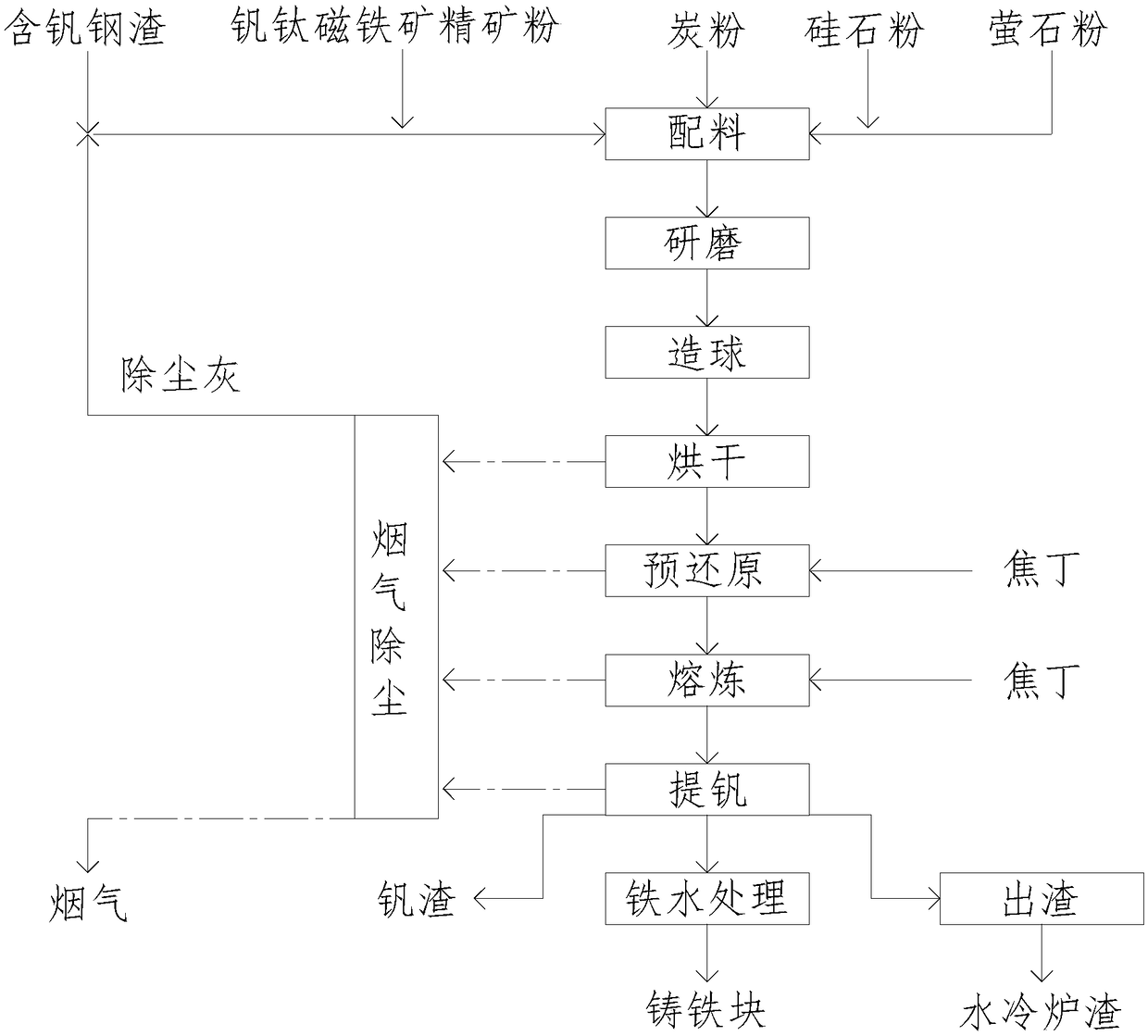

[0063] A recovery process for vanadium in vanadium-containing steel slag, comprising:

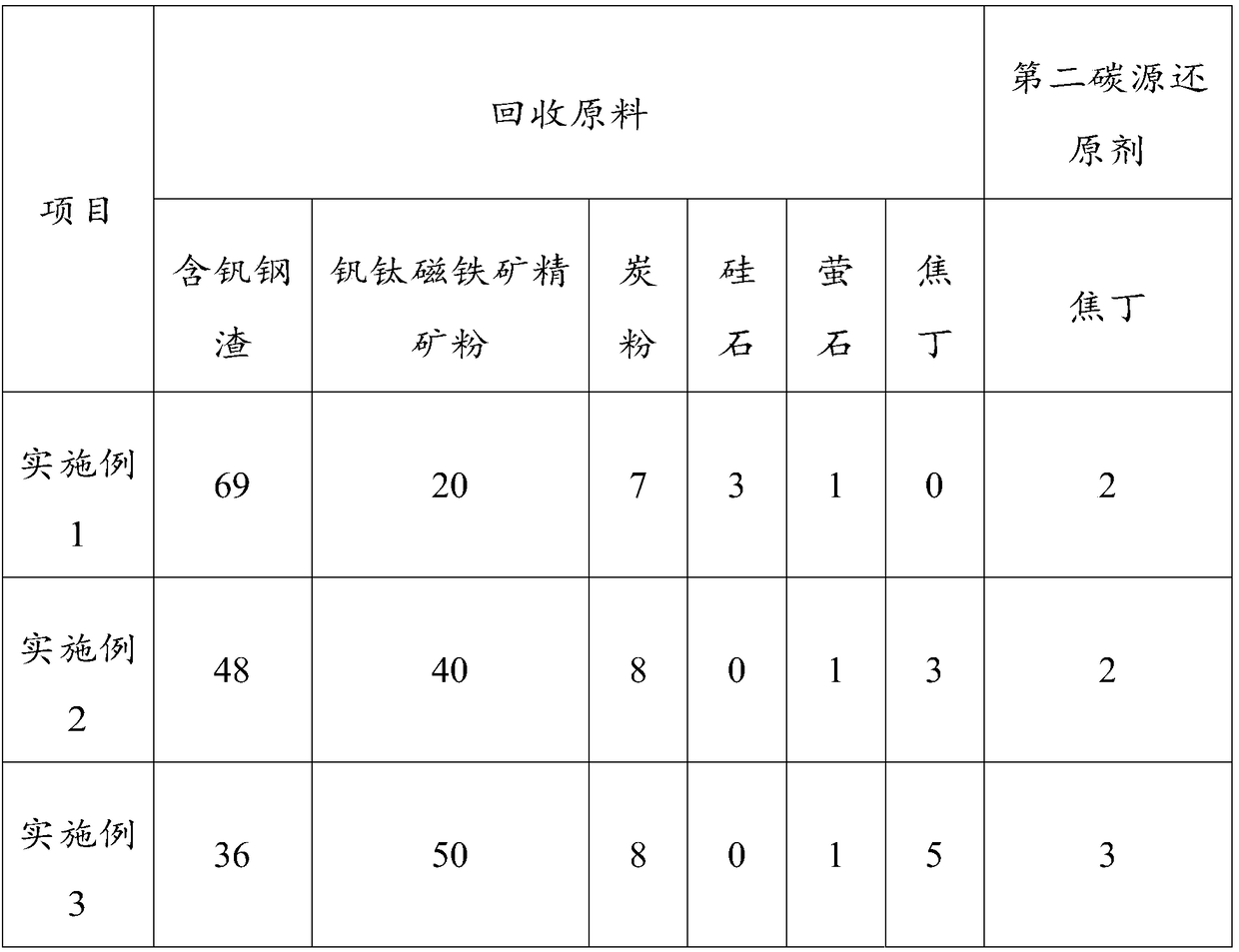

[0064] a. Ingredients, the specific material ratio is shown in Table 1.

[0065] b. Grinding: Put the recycled raw material obtained in step a into a ball mill for grinding and adjust the water content to make pellets.

[0066] c. Ball making: the grinding material obtained in step b is pressed into balls through a ball pressing machine.

[0067] d. Drying: put the spherical material obtained in process c into a cylinder dryer for drying.

[0068] e. Pre-reduction: put the dried material obtained in process d into the rotary kiln for pre-reduction treatment.

[0069] f. Smelting: Put the pre-reduced material obtained in process e into the submerged arc furnace, and add a certain amount of coke for smelting at the same time. See Table 1 for the amount of material.

[0070] g. Vanadium extraction: After smelting for a certain period of time, put the vanadium-containing molten iron obtained...

Embodiment 4-5

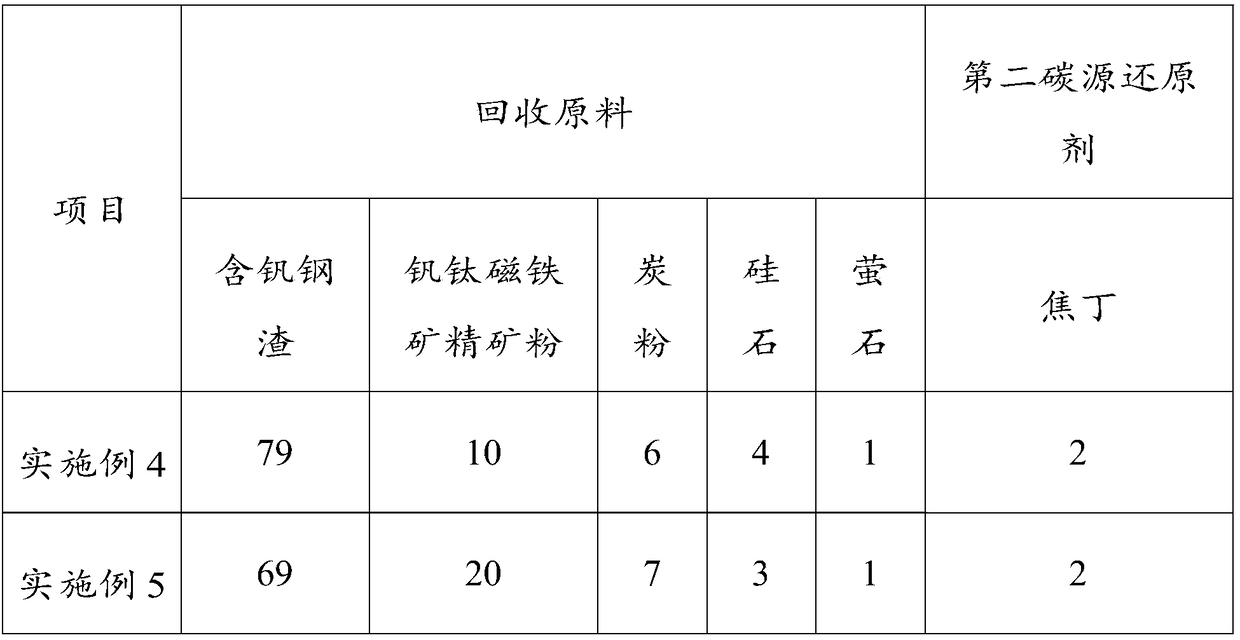

[0076] A recovery process of vanadium in vanadium-containing steel slag, the difference from the recovery process of Examples 1-3 is: the material ratio is shown in Table 2, the rotary kiln is cancelled, and the pre-reduction treatment in the operation e is carried out in the submerged arc furnace conduct.

[0077] The second material formula of table 2 (dry matter mass percent / %)

[0078]

[0079] It should be noted that the mass percentage of dry matter in Table 1 and Table 2 refers to the ratio of the dry matter mass of each component to the total dry matter mass of recycled raw materials, taking the total dry matter mass of recycled raw materials as a reference.

[0080] The yield of the recovery process of vanadium in the vanadium-containing steel slag provided in Examples 1-5 is analyzed with reference to relevant metallurgical examples, and under the situation of adjusting smelting temperature and smelting time, the recovery of vanadium and iron The rate can reach m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com