Preparation method of antibacterial shape memory fiber

A memory fiber, memory technology, applied in wet spinning, chemical post-treatment of synthetic polymer rayon, single-component polyurethane rayon, etc., can solve the problem of low yield, uneven spinning, and long spinning time and other problems, to achieve the effect of good shape memory function, broad-spectrum antibacterial activity, and good cytocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

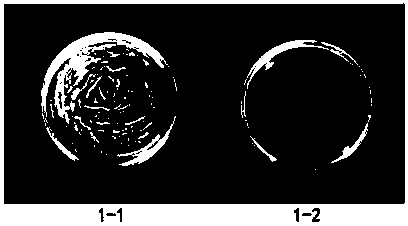

Embodiment 1

[0022] This embodiment provides an antibacterial shape memory fiber, which is formed by compounding shape memory polyurethane and antibacterial agent polyhexamethylene biguanide hydrochloride through spinning technology, and has both shape memory performance and antibacterial function. The detailed preparation process is as follows: dissolve shape memory polyurethane in dimethylacetamide, stir at 80°C for 6h to obtain a homogeneous solution with a mass fraction of 25wt%; configure the antibacterial agent polyhexamethylene biguanide hydrochloride into The aqueous solution with a mass fraction of 10wt% is used as a coagulation bath for wet spinning, and the spinning parameters are set as follows: the inner diameter of the spinneret is 0.51mm, and the draw ratio of the spinneret is -10%; The fibers were dried at room temperature for 24 hours.

[0023] Antibacterial performance test, mechanical strength performance test, shape memory performance test and cytocompatibility test are...

Embodiment 2

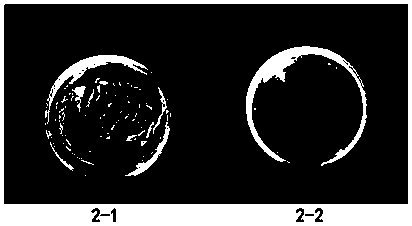

[0027] This embodiment provides an antibacterial shape memory fiber, which is formed by compounding shape memory polyurethane and antibacterial agent 1-chloro-2,2,6,6-tetramethyl-4-piperidinol through spinning technology, Both shape memory performance and antibacterial function. The detailed preparation process is as follows: dissolve shape memory polyurethane in dimethylacetamide, stir at 80°C for 6h to obtain a homogeneous solution with a mass fraction of 35wt%; -Tetramethyl-4-piperidinol is configured into an aqueous solution with a mass fraction of 20 wt%, and uses it as a coagulation bath for wet spinning. The spinning parameters are set as follows: the inner diameter of the spinneret is 0.51 mm, The draw ratio is -10%; after spinning, the fibers are collected and dried at room temperature for 24 hours.

[0028] Antibacterial performance test, mechanical strength performance test, shape memory performance test and cytocompatibility test are carried out to the fiber that ...

Embodiment 3

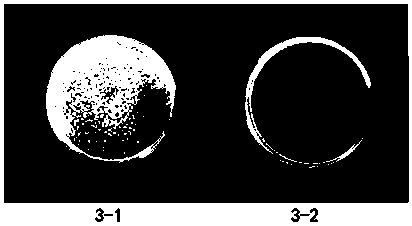

[0030] This embodiment provides an antibacterial shape memory fiber, which is formed by compounding shape memory polyurethane and antibacterial carbolic acid through spinning technology, and has both shape memory performance and antibacterial function. The detailed preparation process is as follows: Dissolve shape memory polyurethane in dimethylacetamide, stir at 80°C for 6h to obtain a homogeneous solution with a mass fraction of 30wt%; prepare the antibacterial agent carbolic acid into an aqueous solution with a mass fraction of 35wt% (65 DEG C of heating and dissolving), use it as coagulation bath, carry out wet spinning, and spinning parameter is set as: spinneret inner diameter is 0.51mm, spinneret drawing ratio is-10%; Collect fiber after spinning finishes It was dried at room temperature for 24 hours.

[0031] Antibacterial performance test, mechanical strength performance test, shape memory performance test and cytocompatibility test are carried out to the fiber that p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com