Micro-nano bubble generating device and method and application thereof in dye wastewater treatment

A technology for micro-nano bubbles and wastewater treatment, applied in the direction of oxidized water/sewage treatment, special compound water treatment, water/sludge/sewage treatment, etc. Oxidation costs are high, achieving good application value, less foam, and less noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

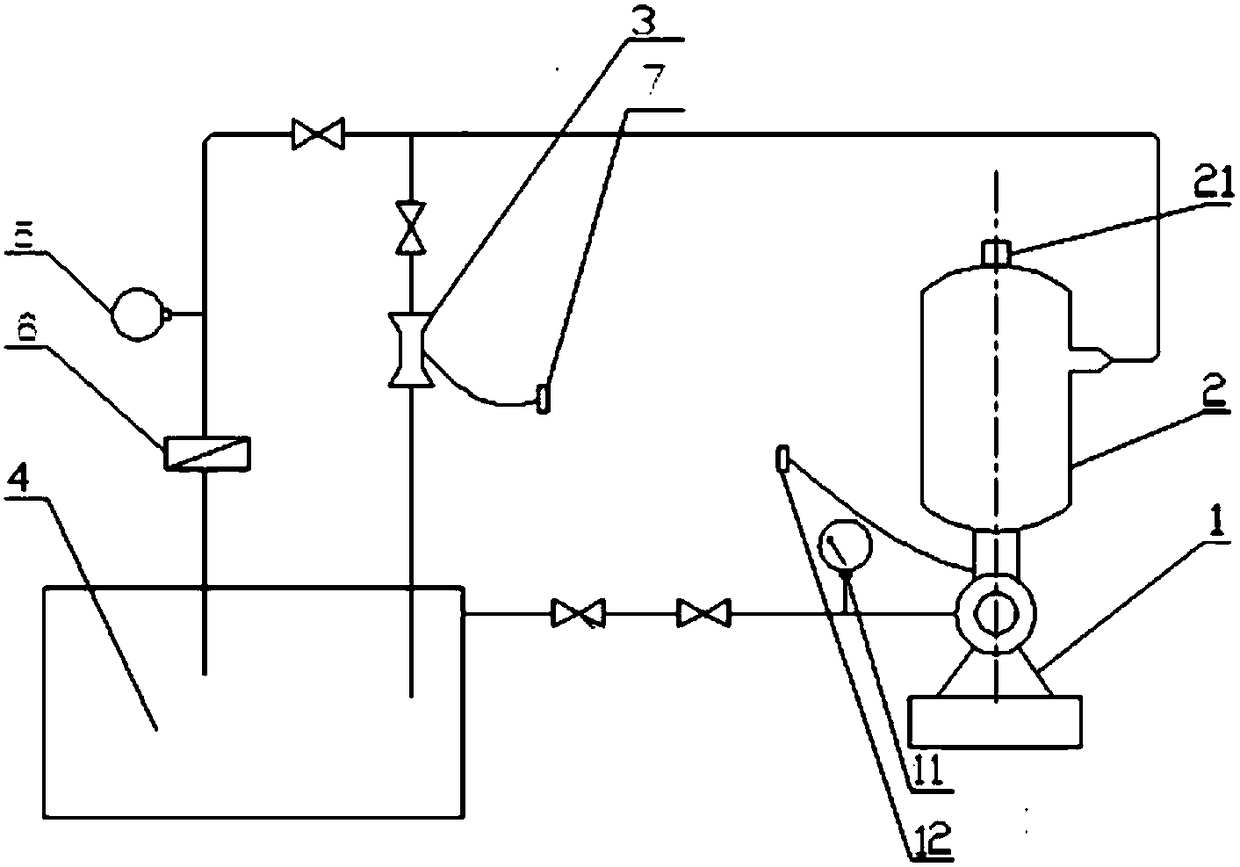

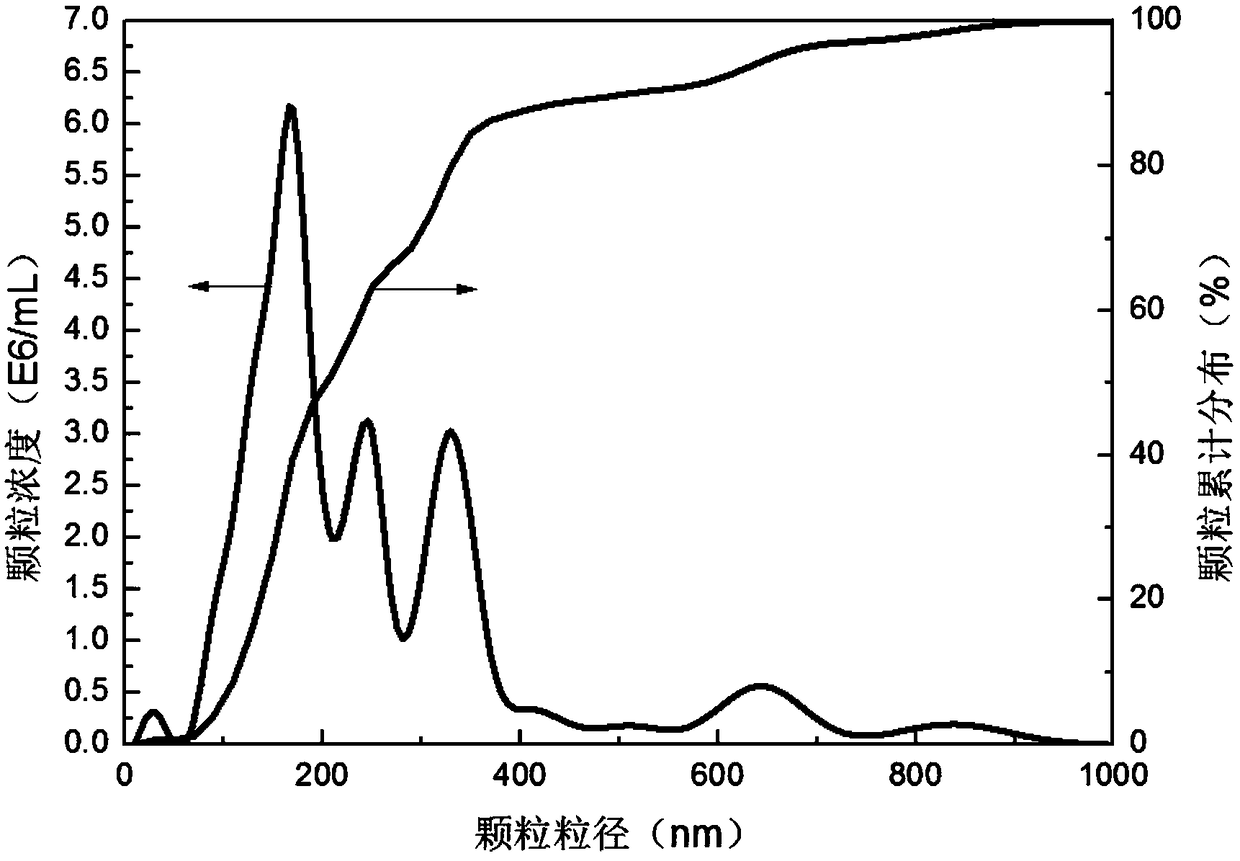

[0099] Embodiment 1 Preparation of micro-nano bubbles

[0100] 1. Connect the gas-liquid mixing pump, pressure dissolving tank, ejector and water tank in sequence to form a nano-micro bubble generating device capable of fluid circulation, and inject pure water into the water tank; among them, the water outlet pipeline of the pressure dissolving tank It is divided into two branches: one pipeline, branch 1, is connected with an ejector, and the other branch, branch 2, is connected with valves, pressure gauges and liquid flow meters;

[0101] 2. Start the functional components in the micro-nano bubble generating device, adjust the gas-liquid mixing pump and the air intake in the ejector, and generate fluid containing micro-nano bubbles.

[0102] Among them, the ratio of the suction volume of the ejector to the flow rate of branch 2 is 1:250, and the ratio of the suction volume of the gas-liquid mixing pump to the flow rate of branch 2 is 1:9.

[0103] Take a certain volume of wa...

Embodiment 2

[0105] Embodiment 2 waste water treatment (pH=3)

[0106] 1. Connect the gas-liquid mixing pump, pressure dissolving tank, ejector and water tank in sequence to form a wastewater treatment device capable of fluid circulation. Inject 6mg / L methylene blue aqueous solution into the water tank to adjust the pH of the aqueous solution to 3; among them, the pressure The water outlet pipeline of the dissolved gas tank is divided into two branches: one pipeline, branch 1, is connected with an ejector, and the other branch, branch 2, is connected with a valve, a pressure gauge and a liquid flow meter;

[0107] 2. Start each functional component in the wastewater treatment device, adjust the gas-liquid mixing pump and the air intake in the ejector, and conduct wastewater treatment at room temperature. Among them, the ratio of the suction volume of the ejector to the flow rate of branch 2 is 1:250, and the ratio of the suction volume of the gas-liquid mixing pump to the flow rate of bran...

Embodiment 3

[0108] Embodiment 3 wastewater treatment (temperature+defoamer)

[0109] The methylene blue wastewater treatment steps are the same as in Example 2, except that the treatment temperature of the methylene blue aqueous solution is further limited to 20°C, and the concentration of the defoamer is 0.00075%.

[0110] Among them, the defoamer used is polyether compounded with silicone defoamer (DT-882D, Guangdong Foshan Xushi Chemical Technology Co., Ltd.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com