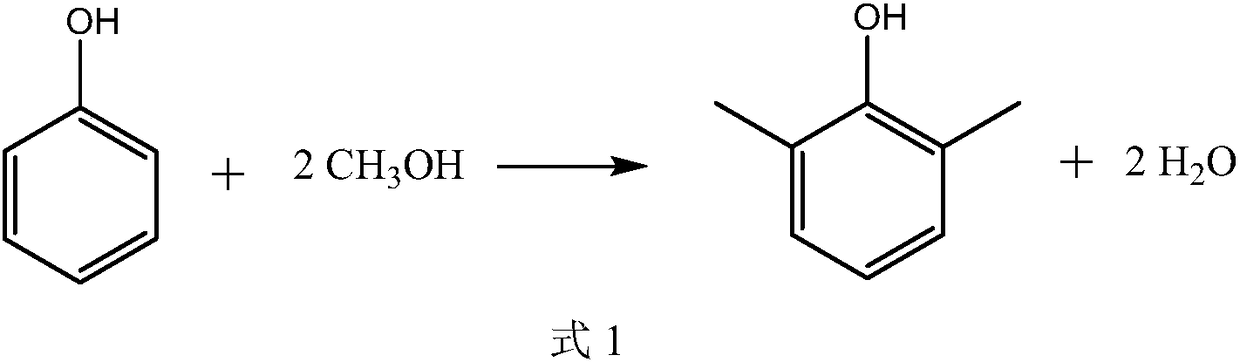

Modified cerium-silicon catalyst, preparation method thereof, and application in 2,6-xylenol synthesis

A technology of dimethylphenol and catalyst, which is applied in the field of new catalytic systems, can solve the problems of high reaction temperature and high decomposition rate of methanol, and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

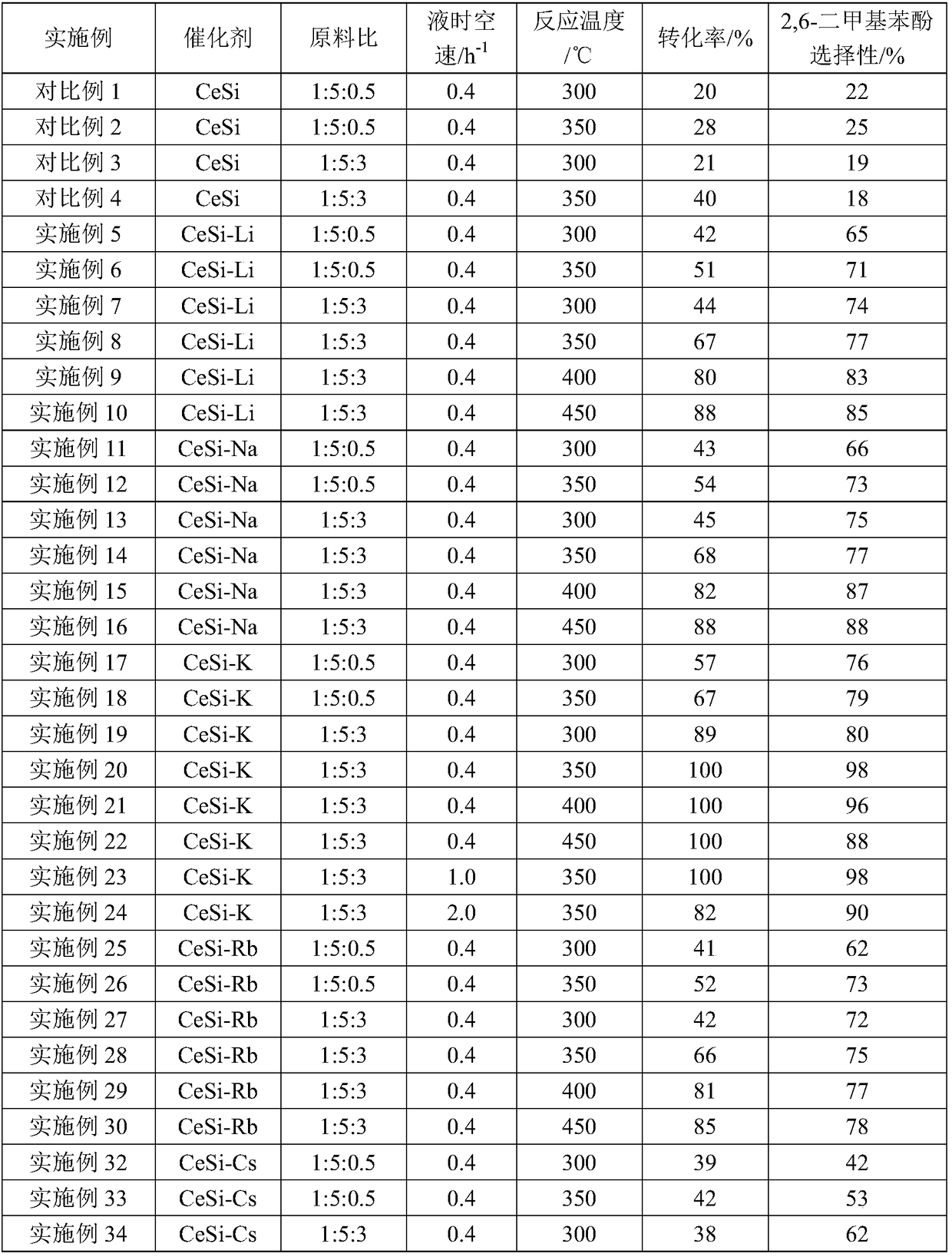

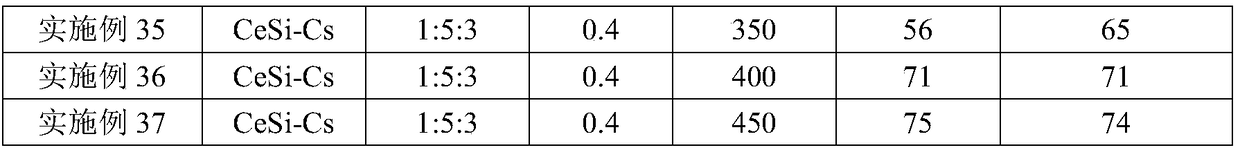

Examples

Embodiment 1

[0015] Modification of embodiment 1 cerium-silicon catalyst-preparation of CeSi-Li

[0016] Weigh 0.5g of anhydrous lithium carbonate and dissolve it in 20ml of ultrapure water to obtain modified solution 1. The pretreated CeSi was impregnated into modification solution 1 for 4 h, then filtered and washed with ultrapure water. The resulting filter cake was dried at 120° C. for 8 hours and then calcined at 500° C. for 8 hours. The obtained solid was pressed into tablets for use, labeled as CeSi-Li, and used in Examples 5-10.

Embodiment 2

[0017] Modification of embodiment 2 cerium-silicon catalyst-preparation of CeSi-Na

[0018] Weigh 0.5 g of anhydrous sodium carbonate and dissolve it in 20 ml of ultrapure water to obtain modified solution 2. The pretreated CeSi was impregnated into modification solution 2 for 4 h, then filtered and washed with ultrapure water. The resulting filter cake was dried at 120° C. for 8 hours and then calcined at 500° C. for 8 hours. The resulting solid was pressed into tablets for use, marked as CeSi-Na, and used in Examples 11-16.

Embodiment 3

[0019] Modification of embodiment 3 cerium-silicon catalyst-preparation of CeSi-K

[0020] Weigh 0.5 g of anhydrous potassium carbonate and dissolve it in 20 ml of ultrapure water to obtain modified solution 3. The pretreated CeSi was impregnated into modification solution 3 for 4 h, then filtered and washed with ultrapure water. The obtained filter cake was dried at 120° C. for 8 hours and then calcined at 500° C. for 8 hours. The obtained solid was pressed into tablets for later use, marked as CeSi-K, and used in Examples 17-24 and Examples 38-48.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com