Method for preparing graphene/copper compound powder

A technology of composite powder and graphene, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of poor uniformity, complicated process, high cost, etc., and achieve simple equipment and operation , cheap price, strong combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the one-step method in the present embodiment prepares the method for graphene / copper composite powder as follows:

[0022] Take 10 kg of copper formate tetrahydrate with a particle size of 100 μm and heat it in an atmosphere heating furnace. Cool down to room temperature to obtain graphene / copper composite powder.

[0023] The product of this embodiment is detected, and the results are as follows: Figure 1-3 shown.

[0024] Depend on figure 1 It can be seen that graphene is relatively thin and can well coat copper particles, and the particle size of copper particles is generally between 0.01 μm and 100 μm.

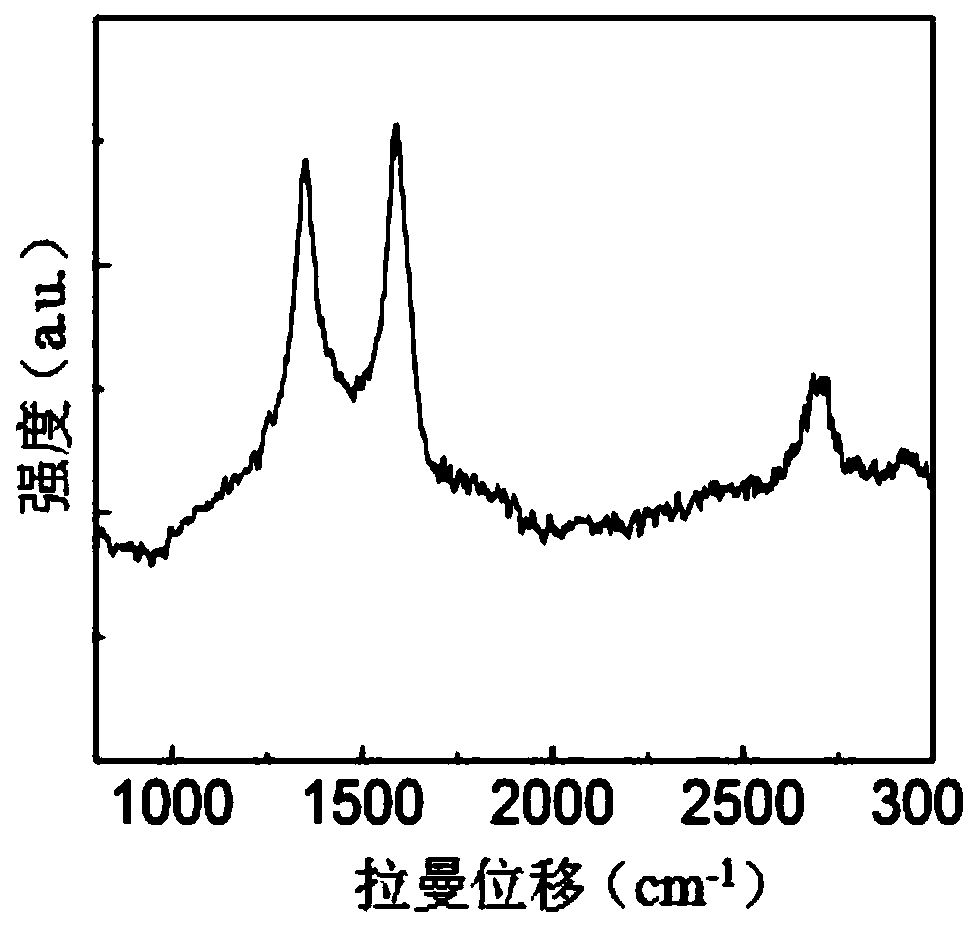

[0025] Depend on figure 2 It can be seen that the peak position of the D peak is 1349.30, the peak position of the G peak is 1589.13, and the peak position of the 2D peak is 2683.04. Therefore, it is determined that the remaining product after being corroded is graphene.

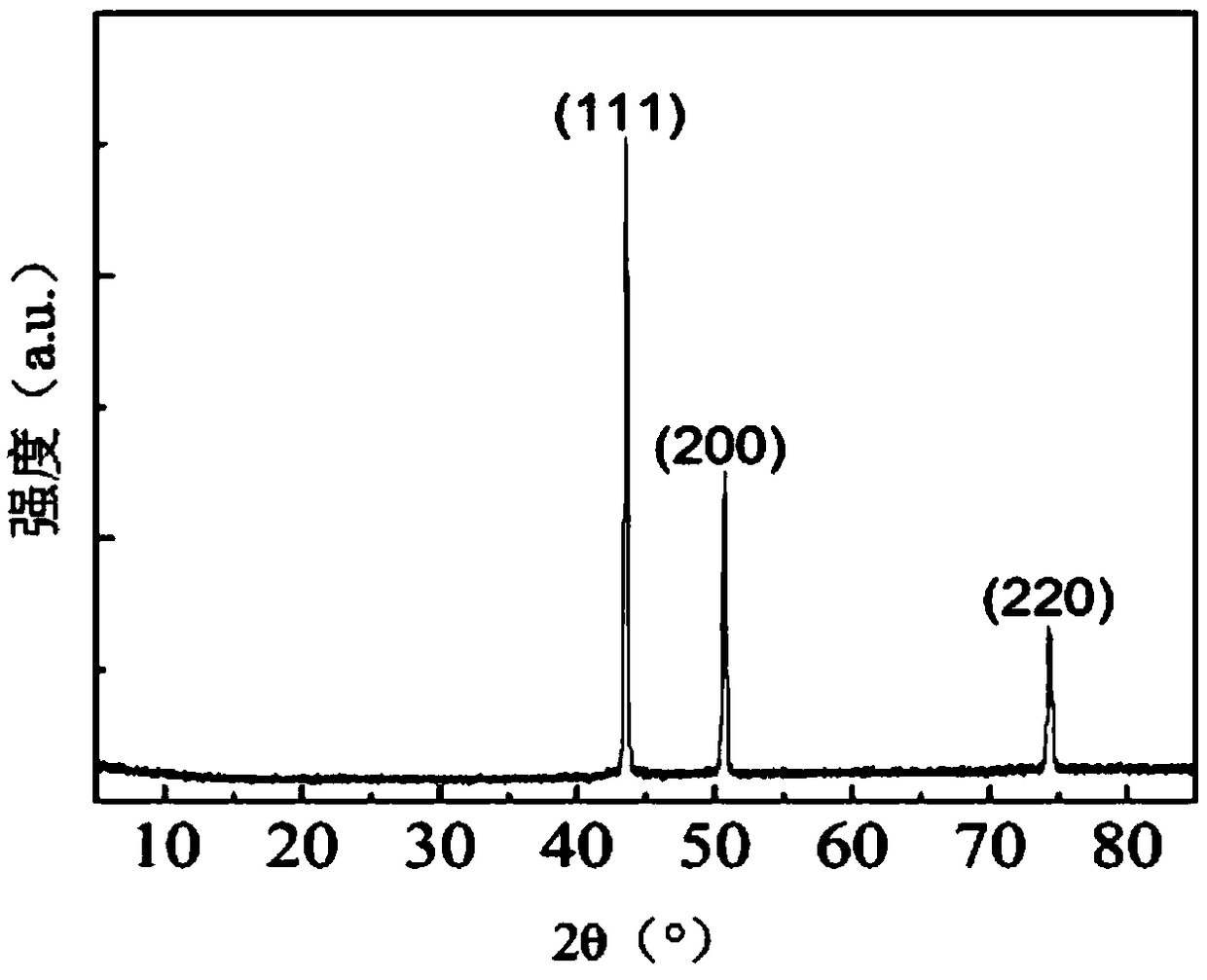

[0026] Depend on image 3 It can be seen that this composite powder on...

Embodiment 2

[0027] Embodiment 2: the one-step method in the present embodiment prepares the method for graphene / copper composite powder as follows:

[0028] Take 10 kg of copper formate tetrahydrate with a particle size of 100 μm and heat it in an atmosphere heating furnace. The atmosphere is Ar gas. Cool to room temperature to obtain graphene / copper composite powder.

[0029] The matrix of the composite powder prepared by the method in this example is pure copper, and the surface of the matrix is graphene, and the graphene is relatively thin. At the same time, the graphene on the surface layer can well coat the copper particles, and the particle size of the copper particles is generally 0.01 μm- Between 100μm.

Embodiment 3

[0030] Embodiment 3: the one-step method in the present embodiment prepares the method for graphene / copper composite powder as follows:

[0031] Take 10 kg of copper formate tetrahydrate with a particle size of 100 μm and heat it in an atmosphere heating furnace. The atmosphere is Ar gas. Cool to room temperature to obtain graphene / copper composite powder.

[0032] The matrix of the composite powder prepared by the method in this example is pure copper, and the surface of the matrix is graphene, and the graphene is relatively thin. At the same time, the graphene on the surface layer can well coat the copper particles, and the particle size of the copper particles is generally 0.01 μm- Between 100μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com