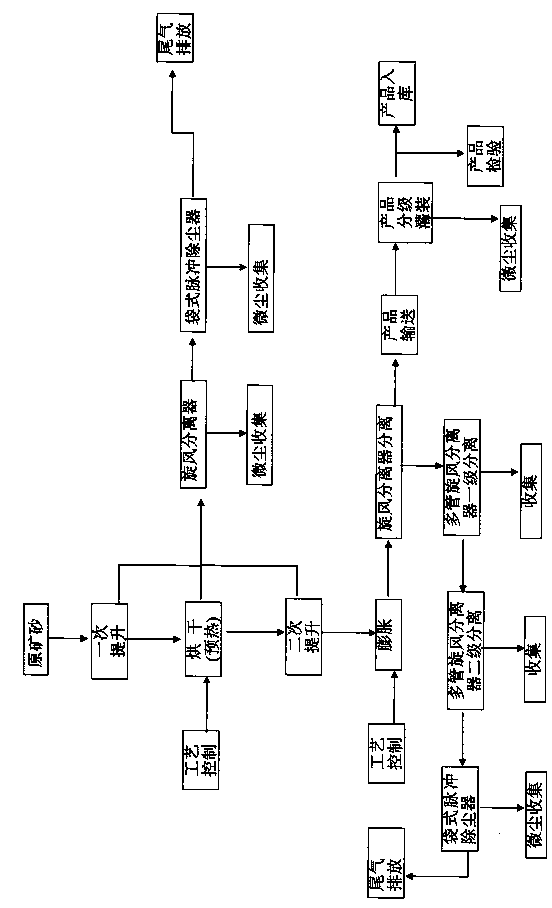

Production process of expanded perlite

A technology of expanded perlite and production process, applied in the field of perlite production, can solve the problems of ore cracking dust volume, high pressure of expansion furnace, waste of raw materials, etc., and achieve the effect of high utilization rate, less waste and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

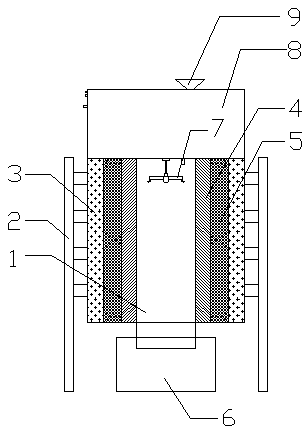

[0026] The step of expanded perlite production technique of the present invention is as follows:

[0027] A. Preheating: Put the pulverized raw ore through a hoist into the preheating drying furnace, and preheat and dry it for 9 minutes at a temperature of 545°C; among them, add raw materials, and before preheating and drying, the dust air in the preheating drying furnace is extracted and separated by the first cyclone separator, and the fine dust separated by the first cyclone separator is collected and solidified, and then added to the primary In the hoist, preheat and dry again; the gas separated by the first cyclone separator is discharged after dust removal by the bag pulse dust collector;

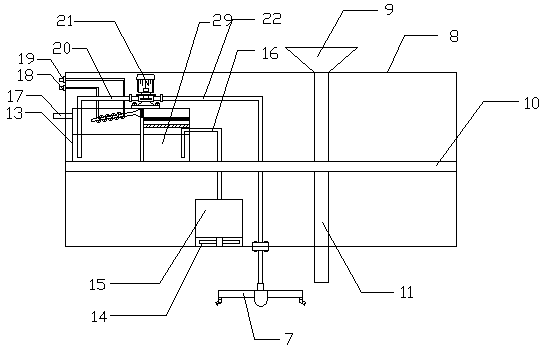

[0028] B. High-temperature expansion: the preheated and dried raw materials in step a enter the expansion furnace through the secondary elevator, and expand for 7s under the condition of 1000°C;

[0029] C. Cyclone separation: The perlite after high temperature expansion is separated...

Embodiment 2

[0032] The step of expanded perlite production technique of the present invention is as follows:

[0033] A. Preheating: Put the pulverized raw ore into the preheating drying furnace through a hoist, and preheat and dry it for 9 minutes at a temperature of 550°C; among them, add raw materials, and before preheating and drying, the dust air in the preheating drying furnace is extracted and separated by the first cyclone separator, and the fine dust separated by the first cyclone separator is collected and solidified, and then added to the primary In the hoist, preheat and dry again; the gas separated by the first cyclone separator is discharged after dust removal by the bag pulse dust collector;

[0034] B. High temperature expansion: the preheated and dried raw materials in step a enter the expansion furnace through the secondary elevator, and expand for 13s under the condition of 1080°C;

[0035] C. Cyclone separation: The perlite after high temperature expansion is separate...

Embodiment 3

[0038] The step of expanded perlite production technique of the present invention is as follows:

[0039]A. Preheating: Put the pulverized raw ore into the preheating drying furnace through a hoist, and preheat and dry it for 8 minutes at a temperature of 557 ° C; among them, add the raw ore before entering the preheating drying furnace raw materials, and before preheating and drying, the dust air in the preheating drying furnace is extracted and separated by the first cyclone separator, and the fine dust separated by the first cyclone separator is collected and solidified, and then added to the primary In the hoist, preheat and dry again; the gas separated by the first cyclone separator is discharged after dust removal by the bag pulse dust collector;

[0040] B. High-temperature expansion: the preheated and dried raw material in step a enters the expansion furnace through the secondary elevator, and expands for 17s under the condition of 980°C;

[0041] C. Cyclone separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com