Method for preparing N-alkyl-4-nitrophthalimide

A technology of alkylphthalimide and nitrophthalimide, which is applied in the field of low-temperature nitration reaction to prepare N-alkyl-4-nitrophthalimide series products, It can solve the problems of low yield of N-alkyl-4-nitrophthalimide, no N-alkylphthalimide has been seen, and difficulty in transferring heat of nitration reaction in time, so as to avoid the phenomenon of overheating , Reduce the amount of nitric acid and the discharge of three wastes, the effect of reducing the amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

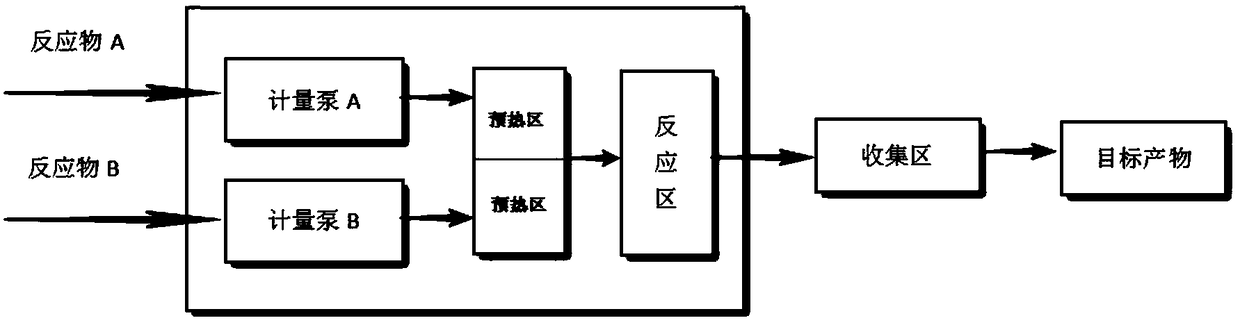

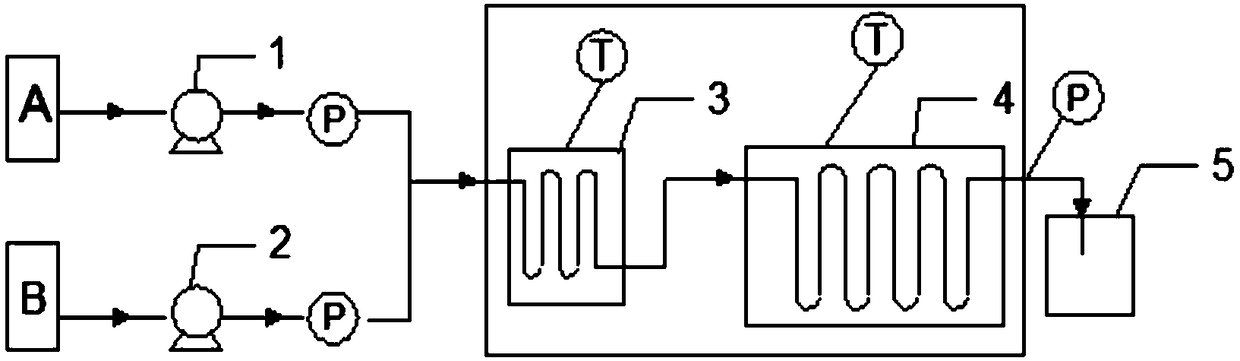

[0047] (1) Refer to image 3 Determine the connection mode of the microchannel reactor, the channel type is a cylindrical straight channel combined with a diamond microchannel structure, the number of microchannel mixed reaction modules is determined according to the flow rate and residence time, and the heat transfer medium is heat transfer oil.

[0048] The N-methylphthalimide-concentrated sulfuric acid solution is regarded as raw material A, and the concentrated nitric acid solution is regarded as raw material B, and the two streams of materials are injected into the reactor through a metering pump at a flow rate of 5ml / min and 20ml / min respectively In the preheating module, after the two stocks of materials are fully preheated respectively, they enter the reaction zone for mixed reaction. At this time, the molar ratio of the concentrated nitric acid and the substrate is controlled to be 1:1, and the mass ratio of the substrate to the concentrated sulfuric acid is 1:1. 1. U...

Embodiment 2

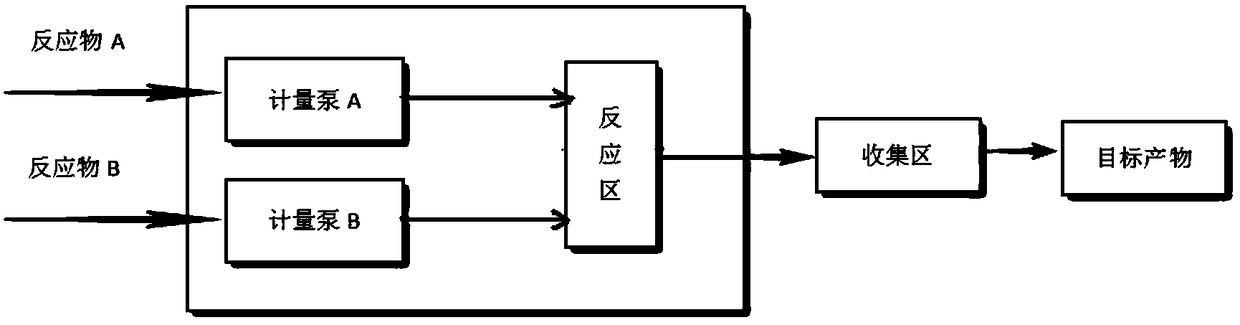

[0050] (1) Refer to image 3 Determine the connection mode of the microchannel reactor and remove the preheating area module. The channel types are cylindrical straight channel and heart-shaped microchannel. The number of microchannel mixed reaction modules is determined according to the flow rate and residence time.

[0051] The N-ethylphthalimide-concentrated sulfuric acid solution is regarded as raw material A, and the concentrated nitric acid solution is regarded as raw material B, and the two materials are injected into the reaction zone through the metering pump at the flow rate of 8ml / min and 20ml / min respectively Carry out mixed residence reaction in, control the mol ratio of concentrated nitric acid and substrate at this moment to be 1.2:1, the mass ratio of substrate and the concentrated sulfuric acid is 1:2, adopt figure 2 In a microchannel reactor, the temperature is controlled at 50°C and the residence time is 150s. The reaction solution is collected quantitative...

Embodiment 3

[0053] (1) Refer to image 3 Determine the connection mode of the microchannel reactor, the channel type is cylindrical straight channel and triangular microchannel structure, the number of microchannel mixed reaction modules is determined according to the flow rate and residence time, and the heat transfer medium is heat transfer oil.

[0054] The N-n-butylphthalimide-concentrated sulfuric acid solution is regarded as raw material A, and the concentrated nitric acid solution is regarded as raw material B, and the two streams of materials are injected into the reactor through the metering pump at the flow rate of 15ml / min and 35ml / min respectively. In the thermal module, after the two streams of materials are fully preheated, they enter the reaction zone for mixed reaction. At this time, the molar ratio of concentrated nitric acid and substrate is controlled to be 1.3:1, and the mass ratio of substrate to concentrated sulfuric acid is 1:4. ,use figure 2 In a microchannel rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com