Method for preparing D-allulose through vacuum spray drying

A technology of vacuum spray drying and psicose, which is applied in the field of preparation of vacuum spray drying D-psicose, can solve problems such as unsatisfactory effect, difficulty in obtaining powder, influence on product yield and quality, etc. The effect of large industrial production and application value, no impact on product quality, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Enzymatic preparation process of D-psicose syrup

[0016] (1) Enzyme reaction: prepare 500 g×L with deionized water -1 D-fructose solution, the amount of enzyme solution added is 30 μL×g -1 For D-fructose, the reaction temperature was 55°C, and the temperature was raised to 100°C after 10 h to inactivate the enzyme.

[0017] (2) Decolorization: add 0.1-5% activated carbon in the dry weight of the feed solution, keep the temperature at 70-100°C for 30 minutes, and remove the activated carbon with a ceramic membrane.

[0018] (3) Isolation: The material liquid is desalinated by cation-anion-cation exchange resin to reduce the conductance, and the conductance is required to be 0~100 μs / cm when the sugar concentration is 30%.

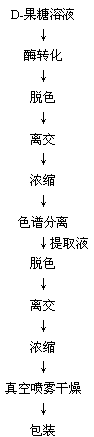

[0019] process such as figure 1 As shown, the D-psicose content of D-psicose obtained after enzymatic conversion of D-fructose reaches 27-30%; Chromatographic separation, re-decolorization with activated carbon, separation and concentr...

Embodiment 2

[0020] Example 2 Preparation of D-psicose powder by vacuum spray drying

[0021] Concentrate D-psicose syrup to a sugar concentration of 40~60%, set the tank temperature to 40~80°C, vacuum degree to 40~80KPa, material preheating temperature to 40~60°C, and finally dry allulone The water content of powdered sugar is 5%, the purity is over 98%, and the yield is 71%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com