Heat treatment method of thorium-based fused salt main container and core shroud

A heat treatment method and main container technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of long supply cycle, increased manufacturing cost, iron ion pollution of equipment, etc., to reduce heat treatment costs and meet manufacturing requirements. , Guarantee the effect of precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

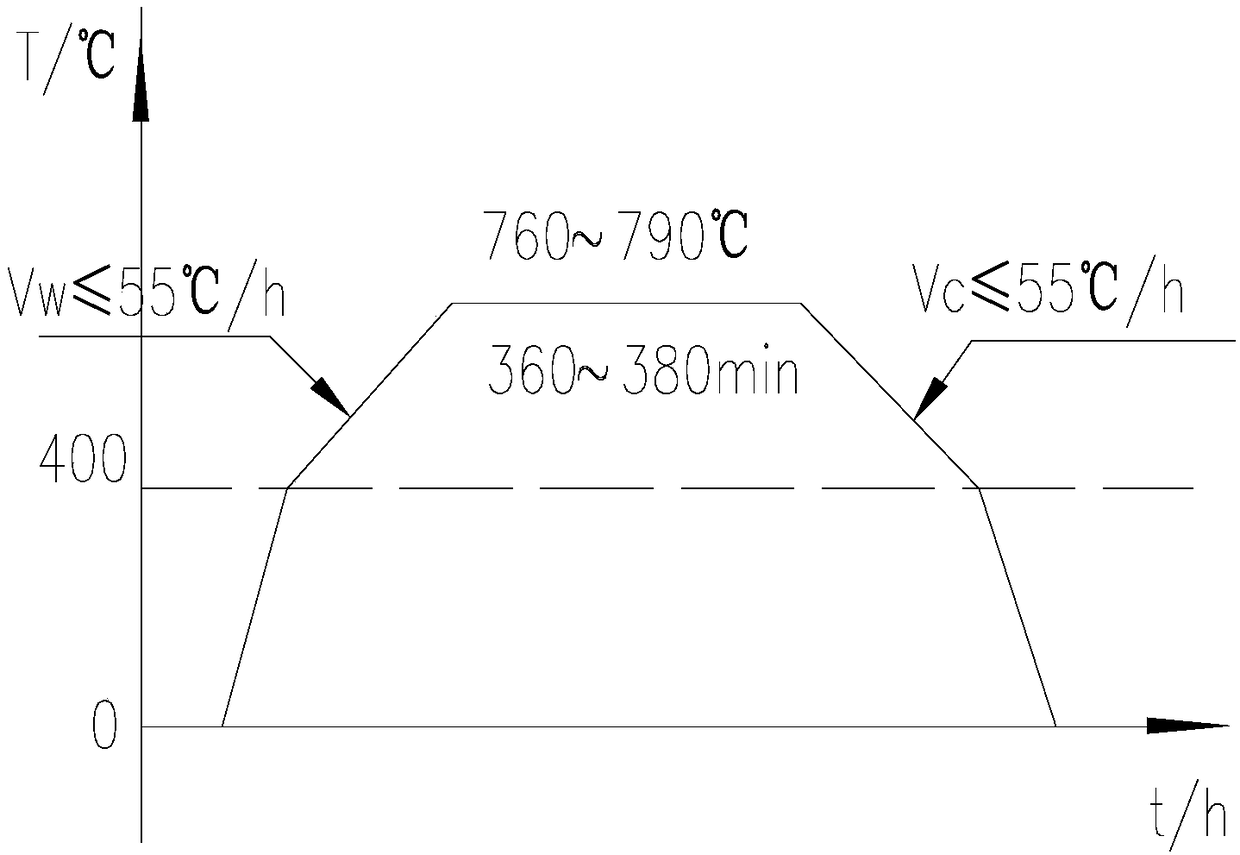

[0023] The method of the present invention is described in detail below in conjunction with accompanying drawing thorium-based molten salt main container and core shroud example:

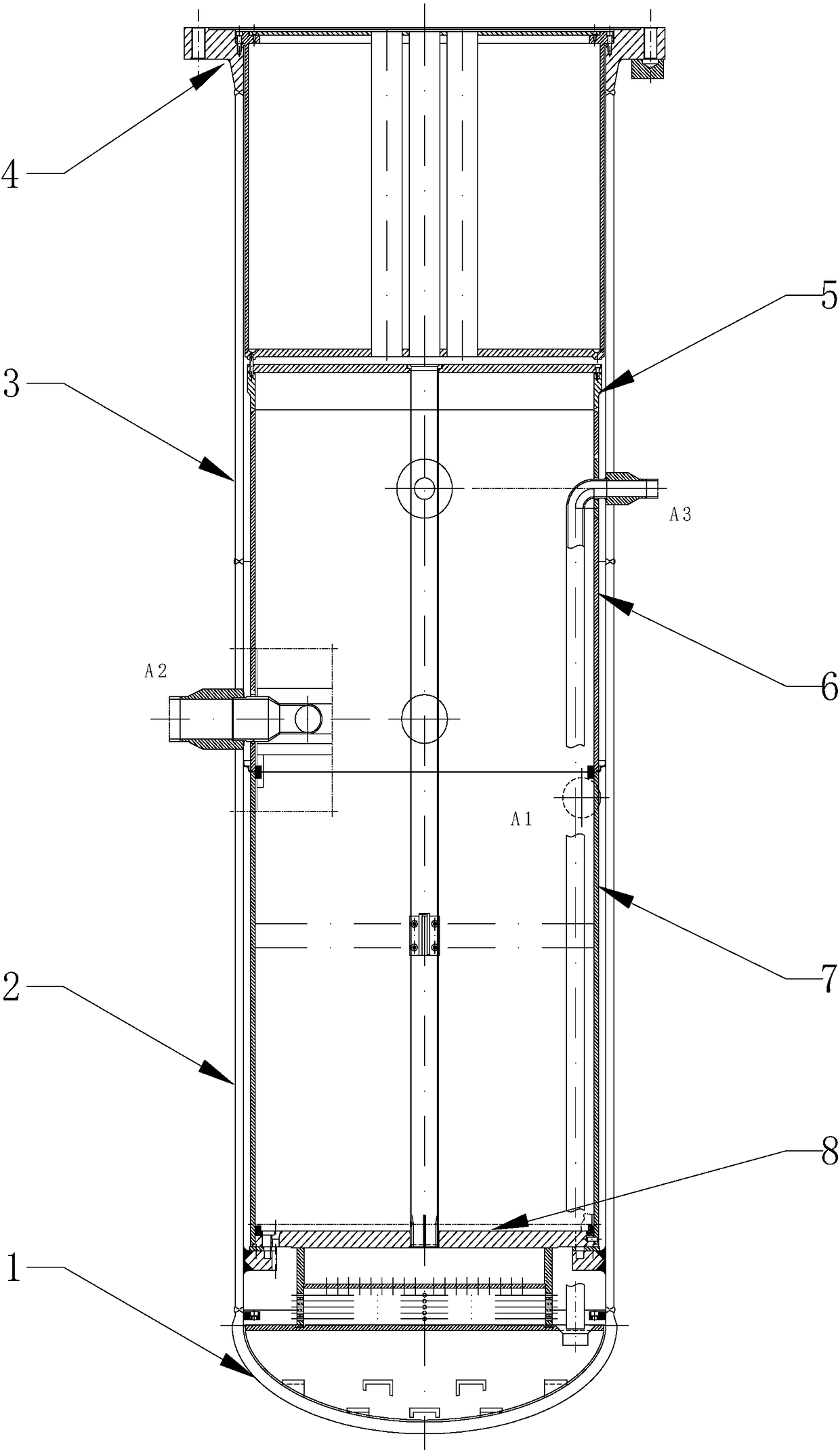

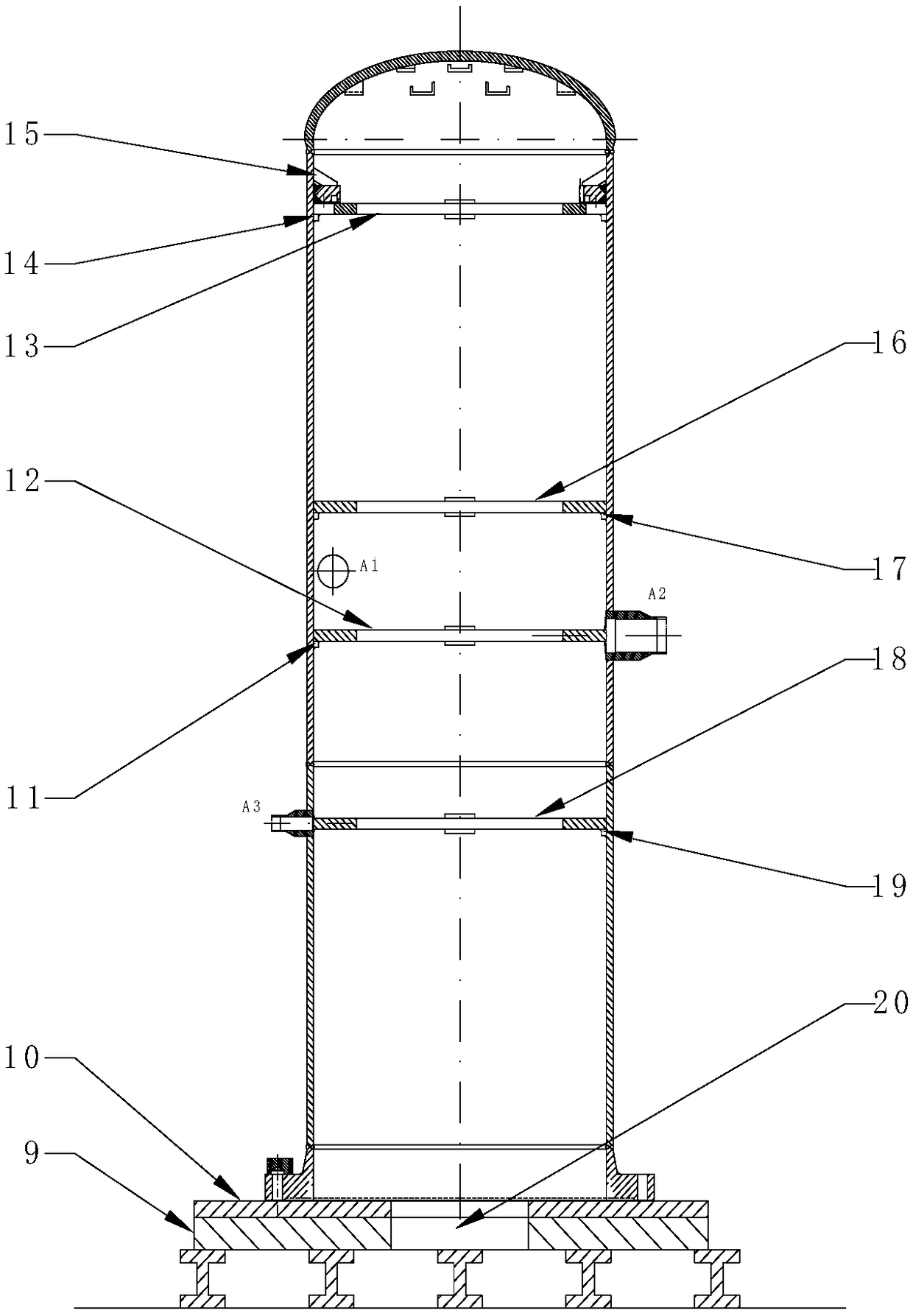

[0024] The example in the accompanying drawings shows that the main container of thorium-based molten salt mainly consists of a lower head 1, a lower cylinder 2, an upper cylinder 3 and an upper flange 4; the core shroud mainly includes an upper reinforcing ring 5, an upper shroud 6, The lower shroud 7 and the shroud bottom plate assembly 8 are formed.

[0025] In order to prevent out-of-tolerance deformation of the equipment during the heat treatment process, save UNS N10003 tooling materials, and reduce the temperature gradient between the inside and outside of the container during the heat treatment process, this application has invented the following heat treatment process and technical means, the details are as follows:

[0026] The heat treatment device of the main container mainly includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com