A kind of preparation device and preparation method of nano-short fiber membrane with porous structure

A technology of porous structure and preparation device, which is applied in the fields of short fiber formation, fiber processing, textile and papermaking, etc., can solve the problems of cumbersome operation, difficult to realize functionalization, unsuitable for mass production, etc., and achieve the effect of simple process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of porous nano short fiber membrane:

[0038] 1) Configure PEO solution, the solute is PEO, the solvent is alcohol and distilled water (volume ratio 1:1), and the solution concentration is 13%;

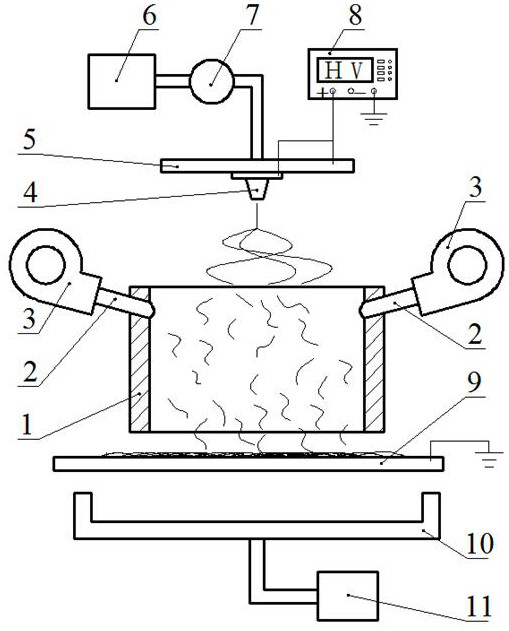

[0039] 2) According to figure 1 Assemble the device, the inner diameter of nozzle 4 is 350 μm. The positive electrode of the high-voltage electrostatic generator 8 is electrically connected to the nozzle 4 and the electrode plate 5, and the metal mesh 9 is grounded. The distance between the electrode plate 5 and the metal mesh 9 is 35cm, the angle between the air inlet pipe 2 and the cyclone chamber 1 is 70° in the axial direction (downward is the positive direction), 60° in the radial direction (inward is the positive direction), and 37° in the tangential direction. Two fans 3 are selected to supply air to the swirl chamber 1 to generate swirl in the inner cavity;

[0040] 3) Put the solution into the solution tank 6, set the flow rate of the liquid pum...

Embodiment 2

[0046] A preparation method of porous nano short fiber membrane:

[0047] 1) Configure PEO solution, the solute is PEO, the solvent is alcohol and distilled water (volume ratio 1:1), and the solution concentration is 10%;

[0048] 2) According to figure 1 Assemble the device, the inner diameter of the nozzle 4 is 210 μm. The positive electrode of the high-voltage electrostatic generator 8 is electrically connected to the nozzle 4 and the electrode plate 5, and the metal mesh 9 is grounded. The distance between the electrode plate 5 and the metal mesh 9 is 30cm, the angle between the air inlet pipe 2 and the cyclone chamber 1 is 70° in the axial direction (downward is the positive direction), 60° in the radial direction (inward is the positive direction), and 37° in the tangential direction. Two fans 3 are selected to supply air to the swirl chamber 1 to generate swirl in the inner cavity;

[0049] 3) Put the solution into the solution tank 6, set the flow rate of the liquid...

Embodiment 3

[0055] A preparation method of porous nano short fiber membrane:

[0056] 1) Configure PVDF solution, the solute is PVDF, the solvent is acetone and DMF mixed solvent (volume ratio is 1:1), and the solution concentration is 16%;

[0057] 2) According to figure 1 Assemble the device, the inner diameter of the nozzle 4 is 210 μm. The positive electrode of the high-voltage electrostatic generator 8 is electrically connected to the nozzle 4 and the electrode plate 5, and the metal mesh 9 is grounded. The distance between the electrode plate 5 and the metal mesh 9 is 25cm, the air inlet pipe 2 and the cyclone chamber 1 are 80° axially (downward is positive), radially (inward is positive) 60°, and tangentially 30°. Two fans 3 are selected to supply air to the swirl chamber 1 to generate swirl in the inner cavity;

[0058] 3) Put the solution into the solution tank 6, set the flow rate of the liquid pump 7 to 150 μl / hr, and a stable solution continuously appears at the nozzle 4; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com