Tire/wheel assembly

A technology for assembling bodies and wheels, applied to pneumatic tires, tire parts, tires, etc., can solve the problems of difficult, unsolved, and unsolved tire problems in tire assembly, improve drivability and durability, and ensure driving stability. The effect of excellent performance and rim assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1~3

[0059] The foamable compound which consists of the formulation of "foams 1-3" described in Table 1 was weighed, and it stirred at room temperature (25 degreeC) for 1 minute. Immediately after pouring into a mold of a predetermined shape, foaming was not observed for about 30 minutes after foaming started. This reactant was further left still for 24 hours to complete foaming and polymerization reaction, and foams 1 to 3 were obtained.

[0060] Using the foams 1 to 3 obtained above, the compressive strength and flexural strength were measured by the following measuring methods.

[0061] compressive strength

[0062] Using the obtained foam, the test piece for a measurement was produced based on JIS A9511. Using this test piece for measurement, a compression test was performed under the conditions of a temperature of 23° C. and a strain rate of 5 mm / min in accordance with JIS A9511, and the compressive strength at a strain of 10% was measured.

[0063] Bending strength

[006...

example 4

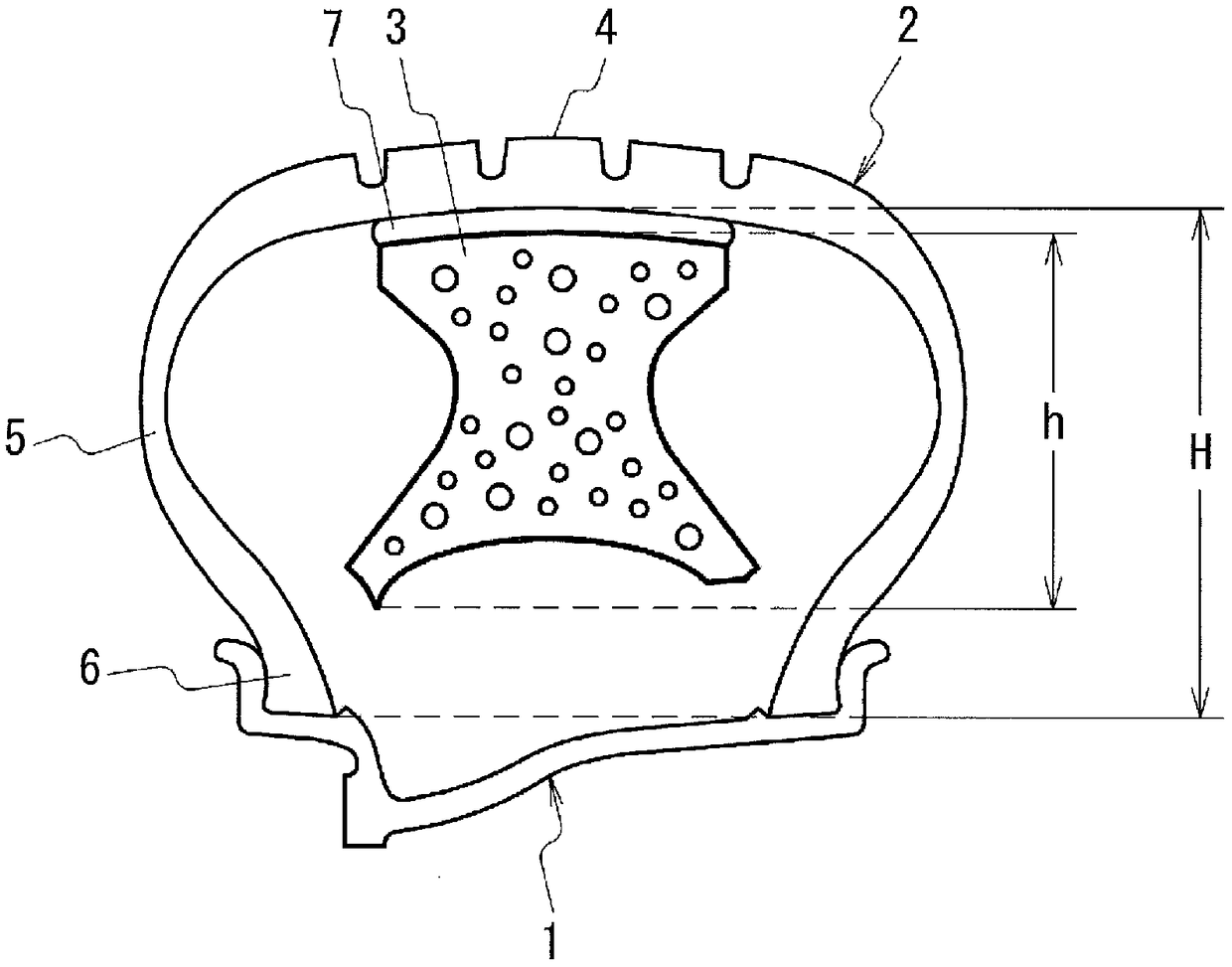

[0071] use form figure 2 The mold for the run-flat support body 3 shown in FIG. The obtained tire / wheel assembly was subjected to a run-flat driving test and its weight was measured by the method described above.

example 5

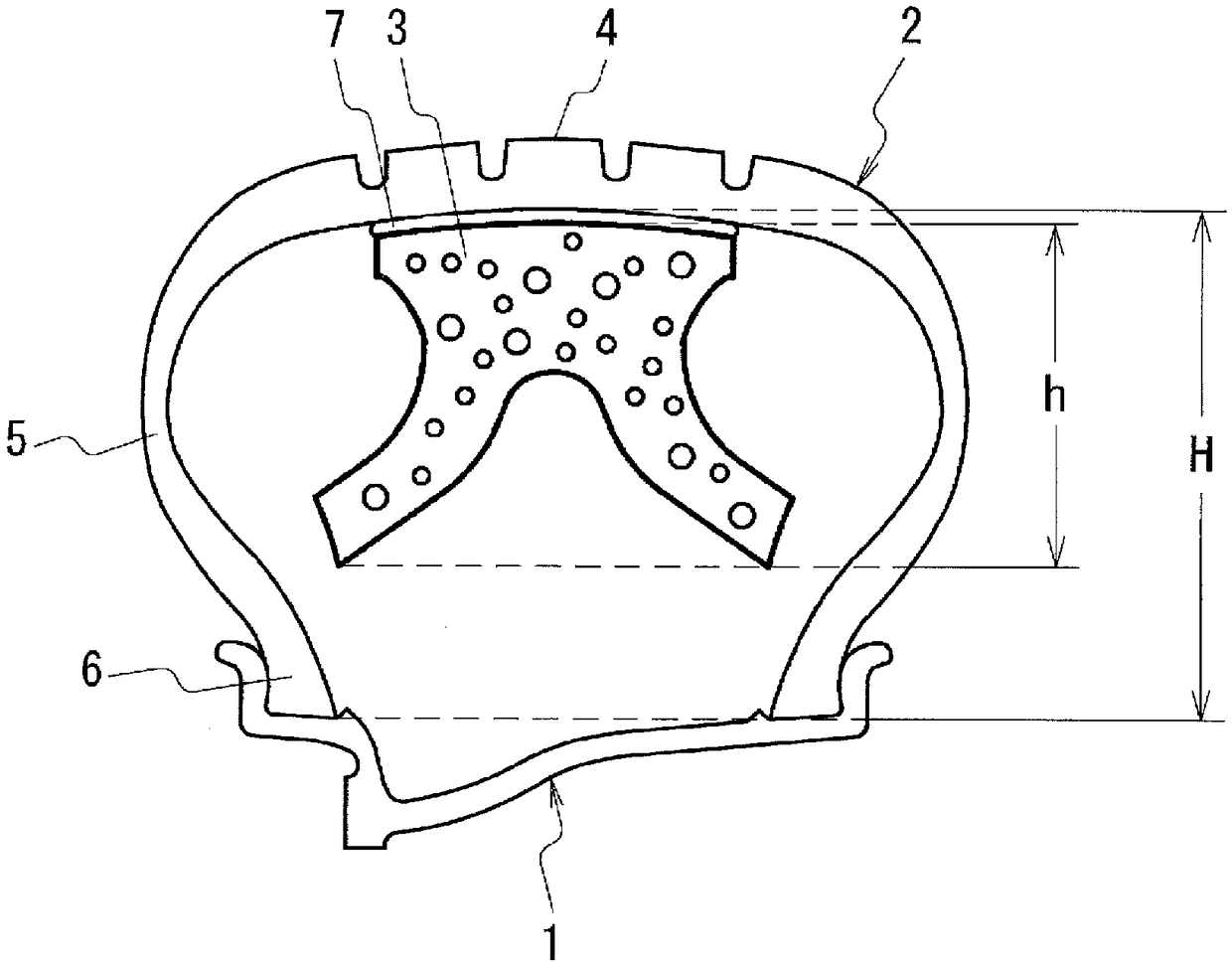

[0073] use form image 3 The mold for the run-flat support body 3 shown in , molds the run-flat support body composed of the above-mentioned foam body 3 . The obtained tire / wheel assembly was subjected to a run-flat driving test and its weight was measured by the method described above.

[0074] [Table 1]

[0075]

[0076] In addition, the kind of raw material used in Table 1 is as follows.

[0077] ・Polyol compound: polycarbonate diol, T5651 manufactured by Asahi Kasei Co., Ltd.

[0078] ・Amine compound: 1,4-diazabicyclo[2.2.2]octane, manufactured by Tokyo Chemical Industry Co., Ltd.

[0079] Catalyst: tin octoate, Neostan U-28 manufactured by Nitto Kasei Co., Ltd.

[0080] Foam stabilizer: silicone oil, FZ3703 manufactured by Toray Dow Corning Corporation

[0081] ・Isocyanate compound 1: polymethylene polyphenyl polyisocyanate, NCO group content rate 31%, Sumidur 44V10 manufactured by Sumika Bayer Urethane Co., Ltd.

[0082] ・Isocyanate compound 2: polymethylene pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com