Ternary precursor material and preparation method thereof

A precursor and slurry technology, applied in chemical instruments and methods, electrical components, nickel compounds, etc., can solve the problems that ternary materials cannot meet the requirements of vehicle battery indicators, and it is difficult to control the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

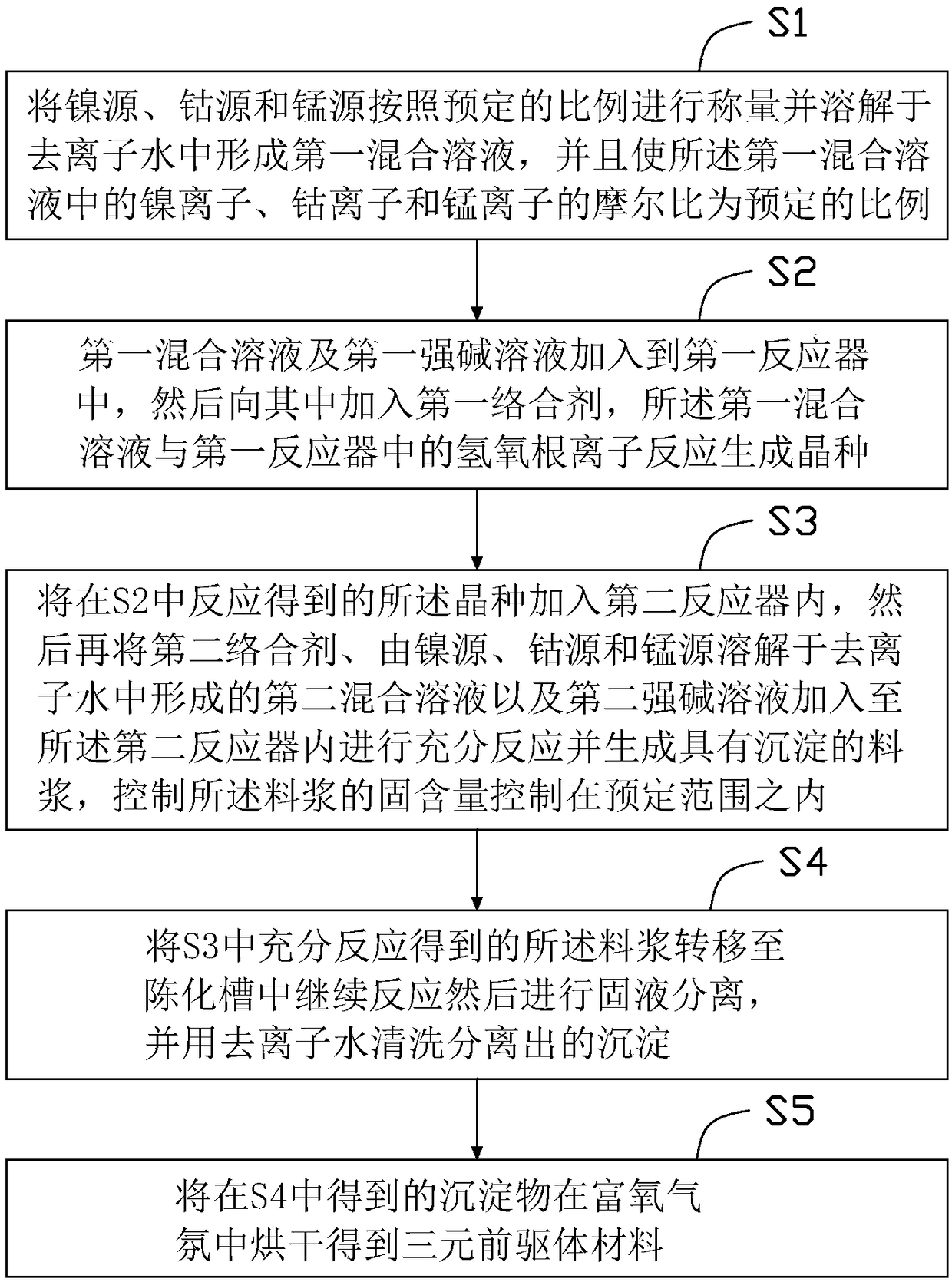

[0029] see figure 1 , is the flow chart of the preparation method of the ternary precursor material provided by the present invention. The preparation method of described ternary precursor material comprises the steps:

[0030] S1, weighing the nickel source, cobalt source and manganese source according to a predetermined ratio and dissolving them in deionized water to form a first mixed solution, and the molar concentration of nickel ions, cobalt ions and manganese ions in the first mixed solution is a predetermined ratio;

[0031] The nickel source, cobalt source and manganese source are all water-soluble salts. Specifically, the nickel source can be a mixture of one or more of nickel sulfate, nickel nitrate and nickel chloride, and the cobalt source can be one or more of cobalt sulfate, cobalt nitrate and cobalt chloride The manganese source can be one or a mixture of manganese sulfate, manganese nitrate and manganese chloride. The molar ratio of nickel ions, cobalt ion...

Embodiment 1

[0057] The nickel source, the cobalt source and the manganese source are weighed according to a predetermined ratio and dissolved in deionized water to form a first mixed solution. And the molar concentration ratio of nickel ions, cobalt ions and manganese ions in the first mixed solution is 5 / 2 / 3.

[0058] The first mixed solution is added to the first reactor, the first reactor is a reactor and the circulation flux is 25m 3 / h. Then add ammoniacal liquor and the first strong alkali solution wherein with constant rate, the concentration of described ammoniacal liquor gradually increases to 30g / L from 0g / L, the duration of adding described ammoniacal liquor is 12 hours; Described first strong alkali solution The ratio of the number of moles of hydroxide ions in the mixture to the number of moles of cations in the first mixed solution is 0.5, and the first strong alkali solution is sodium hydroxide solution.

[0059] The reaction temperature of the reaction environment in the...

Embodiment 2

[0065] The nickel source, the cobalt source and the manganese source are weighed according to a predetermined ratio and dissolved in deionized water to form a first mixed solution. And the molar concentration ratio of nickel ions, cobalt ions and manganese ions in the first mixed solution is 3 / 3 / 3.

[0066] The first mixed solution is added to the first reactor, the first reactor is a reactor and the circulation flux is 15m 3 / h. Then add ammoniacal liquor and the first strong alkali solution wherein with constant rate, the concentration of described ammoniacal liquor gradually increases to 15g / L from 0g / L, the duration of adding described ammoniacal liquor is 24 hours; Described first strong alkali solution The ratio of the number of moles of hydroxide ions in the solution to the number of moles of cations in the first mixed solution is 1, and the first strong alkali solution is a sodium hydroxide solution.

[0067] The reaction temperature of the reaction environment in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com