Fructus lycii licorice root solid beverage and preparation method thereof

A technology for solid beverages and licorice, applied in food science and other directions, to achieve the effects of good dispersion, not easy to absorb moisture and agglomerate, and increase bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

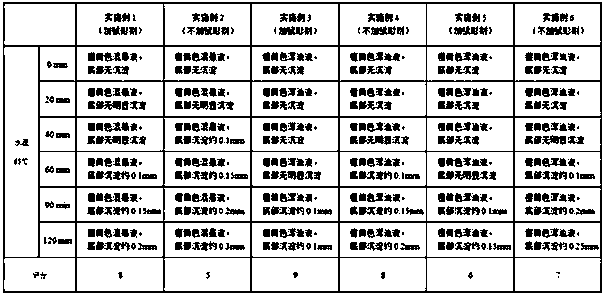

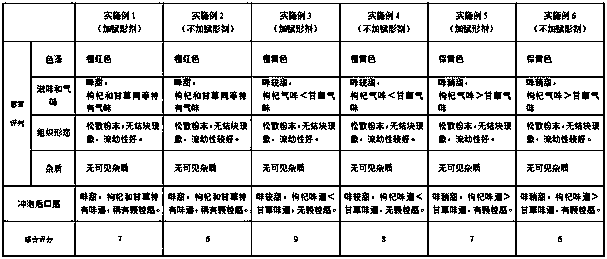

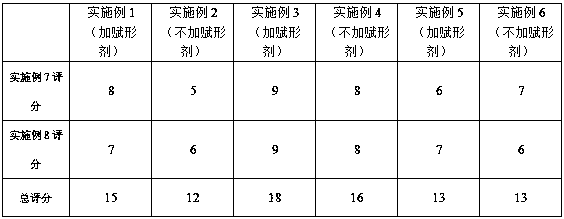

Examples

preparation example Construction

[0054] A preparation method of wolfberry licorice solid drink, comprising the steps of:

[0055]A, wolfberry whole powder preparation

[0056] A1, cleaning

[0057] Remove the stalks and peduncles of the dried wolfberry fruit, rinse to remove the dust and drain the water;

[0058] A2. Crush with water

[0059] The dried wolfberry fruit is mixed with water and crushed;

[0060] A3, solid-liquid separation

[0061] Separating the pulverized liquid from solid to liquid, and filtering the solid for subsequent use;

[0062] A4, dry

[0063] Dry the filtered solids;

[0064] A5, coarse crushing

[0065] Crush the dry matter into granules;

[0066] A6, secondary crushing

[0067] Secondary pulverization of coarse powder particles to superfine powder level or nanometer level to obtain wolfberry whole powder;

[0068] B, preparation of licorice extract

[0069] B1, Glycyrrhiza rhizome crushed water extraction

[0070] Glycyrrhizae rhizomes are crushed, and water is added to...

Embodiment 1

[0098] Weigh 750 g of the whole dried wolfberry fruit with the stem removed, and rinse with a small amount of water. After draining, add 4500 g of distilled water, place it in a dry-wet dual-purpose pulverizer and pulverize for 1 min, and the speed of the pulverizer is 18000 rpm. Centrifugal filtration, rotating speed 12000 rpm, filter cloth pore size 500 mesh. Fluidized bed drying, the bed temperature is 58°C, the air flow rate is 55m³ / h, and the loading per unit area is 2.5kg / ㎡. The dried wolfberry is placed in a pulverizer and pulverized so that the particle size is ≤150um. The sieved Lycium barbarum powder was subjected to airflow ultrafine grinding, and the particle size was ≤5um to obtain 631.6g of Lycium barbarum powder. Among them, the moisture content of whole powder of wolfberry is ≤3.4%, the content of wolfberry red pigment is 1.06‰, and the content of monosaccharide of wolfberry is 1.08‰.

[0099] Glycyrrhizae was crushed to pass through 80 mesh sieve, weighed 4...

Embodiment 2

[0102] Weigh 700 g of the dried wolfberry fruit with the stem removed, and rinse with a small amount of water. After draining, add 7000 g of distilled water, place it in a dry-wet dual-purpose pulverizer and pulverize for 1 min, and the speed of the pulverizer is 21000 rpm. Centrifugal filtration, rotating speed 6000 rpm, filter cloth pore size 400 mesh. Lycium barbarum filter cake was placed in a heat pump dryer at a temperature of 60°C and an air volume of 2000-3000㎥ / h, and dried for 2.5 hours. The dried wolfberry is placed in a pulverizer and pulverized so that the particle size is ≤180um. The sieved Lycium barbarum powder is subjected to airflow ultrafine grinding, and the particle size is ≤5um to obtain 584.5g of Lycium barbarum powder. Among them, the moisture content of whole powder of wolfberry is ≤3.6%, the content of wolfberry red pigment is 1.05‰, and the content of monosaccharide of wolfberry is 1.76‰.

[0103] Glycyrrhizae was crushed to pass through a 60-mesh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com