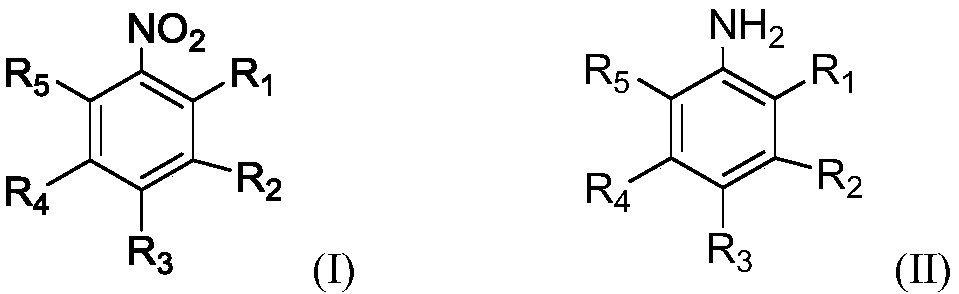

Preparation of sulfur-doped activated carbon catalyst loaded with noble metal and application of sulfur-doped activated carbon catalyst loaded with noble metal in halogenated aromatic nitro-compound hydrogenation reaction

A noble metal catalyst and aromatic nitro group technology, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, amino compound preparation, etc. It can solve the problems of poor stability, poor selectivity, easy loss, etc. , to achieve the effect of many application times, low cost, and not easy to reunite and lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

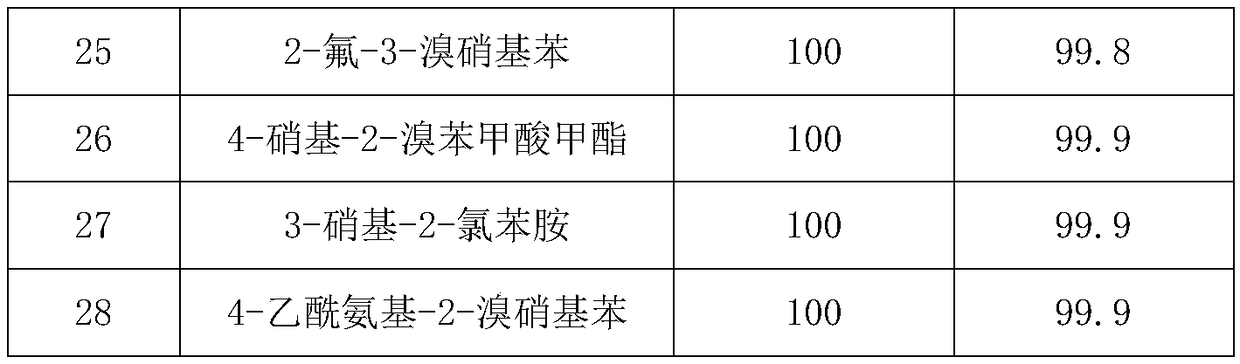

Examples

Embodiment 1

[0031] Weigh Na 2 S·9H 2 O 1.4981g, add deionized water to make 50mL solution, mix well with 10g activated carbon, hydrothermally treat in a high-pressure hydrothermal reactor at 180°C for 10h; filter after cooling to room temperature, wash with a large amount of deionized water until the filtrate is neutral , The resulting filter cake was vacuum-dried at 110°C for 12 hours to obtain sulfur-doped activated carbon. Then 2.5g of the above-mentioned sulfur-doped activated carbon was made into a slurry with deionized water at a ratio of 1:3, and 0.5mL of H 2 PdCl 4 solution (Pd content is 0.05g / mL), stirred for 30min; then added 0.5mL sodium acetate solution (0.1g / mL), stirred for 30min; adjusted the pH value of the solution to 7-9 with 0.1g / mL NaOH solution, and continued to stir 30min; slowly add 0.5mL formaldehyde solution (37%-40%) dropwise, and continue to stir for 30min; filter, wash the filter cake with deionized water, and vacuum dry the filter cake at 110°C for 12h to ...

Embodiment 2

[0033] Weigh Na 2 S·9H 2 O 3.8216g, add 50mL deionized water to make a solution, mix with 10g activated carbon evenly, and hydrothermally treat in a high-pressure hydrothermal reactor at 200°C for 24h; filter after cooling to room temperature, wash with a large amount of deionized water until the filtrate is neutral , The resulting filter cake was vacuum-dried at 110°C for 12 hours to obtain sulfur-doped activated carbon. Then 2.5 g of the above-mentioned sulfur-doped activated carbon was made into a slurry with deionized water at a ratio of 1:5, and 1 mL of H 2 PdCl 4 Solution (Pd content is 0.05g / mL), stir for 100min; then add 1.5mL sodium acetate solution (0.1g / mL), stir for 100min; use 0.1g / mL KOH solution to adjust the pH value of the solution to 7-9, continue to stir 100 min; slowly add 1 mL of formaldehyde solution dropwise, and continue to stir for 100 min; filter, wash the filter cake with deionized water, and vacuum dry the filter cake at 110°C for 12 h to obtain ...

Embodiment 3

[0035] Weigh Na 2 S·9H 2O 7.4934g, add 100mL of deionized water to make a solution, mix well with 10g of activated carbon, hydrothermally treat in a high-pressure hydrothermal reactor at 250°C for 36h; filter after cooling to room temperature, wash with a large amount of deionized water until the filtrate is neutral , The resulting filter cake was vacuum-dried at 110°C for 12 hours to obtain sulfur-doped activated carbon. Then 2.5g of the above-mentioned sulfur-doped activated carbon was made into a slurry with deionized water at a ratio of 1:10, and 2.5mL of H 2 PdCl 4 Solution (Pd content is 0.05g / mL), stir for 60min; then add 2.5mL sodium acetate solution (0.1g / mL), stir for 60min; use 0.1g / mL NaOH solution to adjust the pH value of the solution to 7-9, continue to stir 60min; slowly add 0.6mL formaldehyde solution (37%-40%) dropwise, and continue to stir for 60min; filter, wash the filter cake with deionized water, and vacuum dry the filter cake at 80°C for 24h to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com