Improved method and device for hydrostatic dissolution of high modulus water glass solid

A high modulus water glass, solid technology, applied in the direction of dissolution method, dissolution, dissolution, etc., can solve the problems of sieve plate adhesion and blocking, low dissolution yield, incomplete dissolution, etc., to achieve low equipment renovation costs and improve filtration performance. , reduce the effect of colloid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

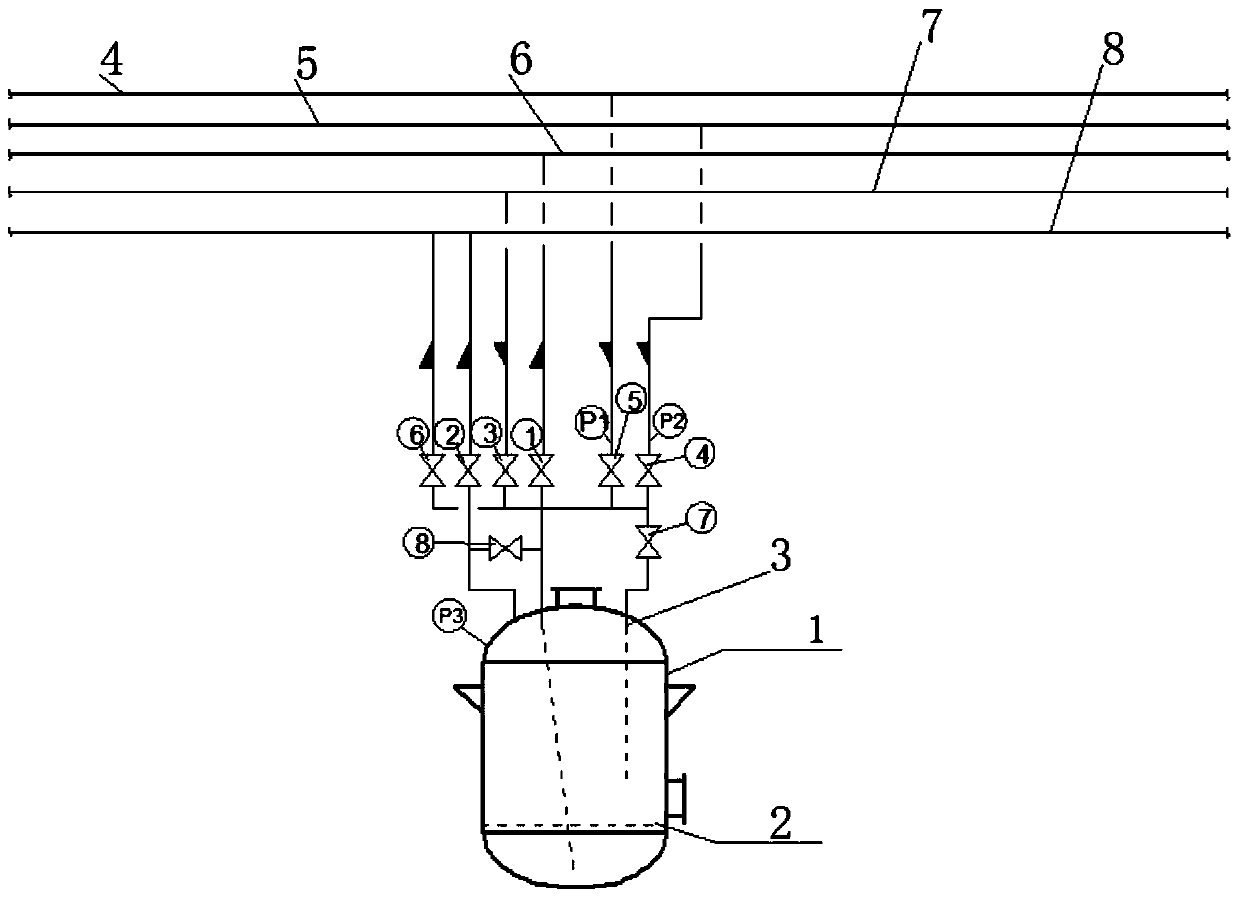

[0057] Such as Figure 1~3 Shown, the present invention provides a kind of improved device of high modulus water glass solid hydrostatic pressure dissolving, comprises static autoclave;

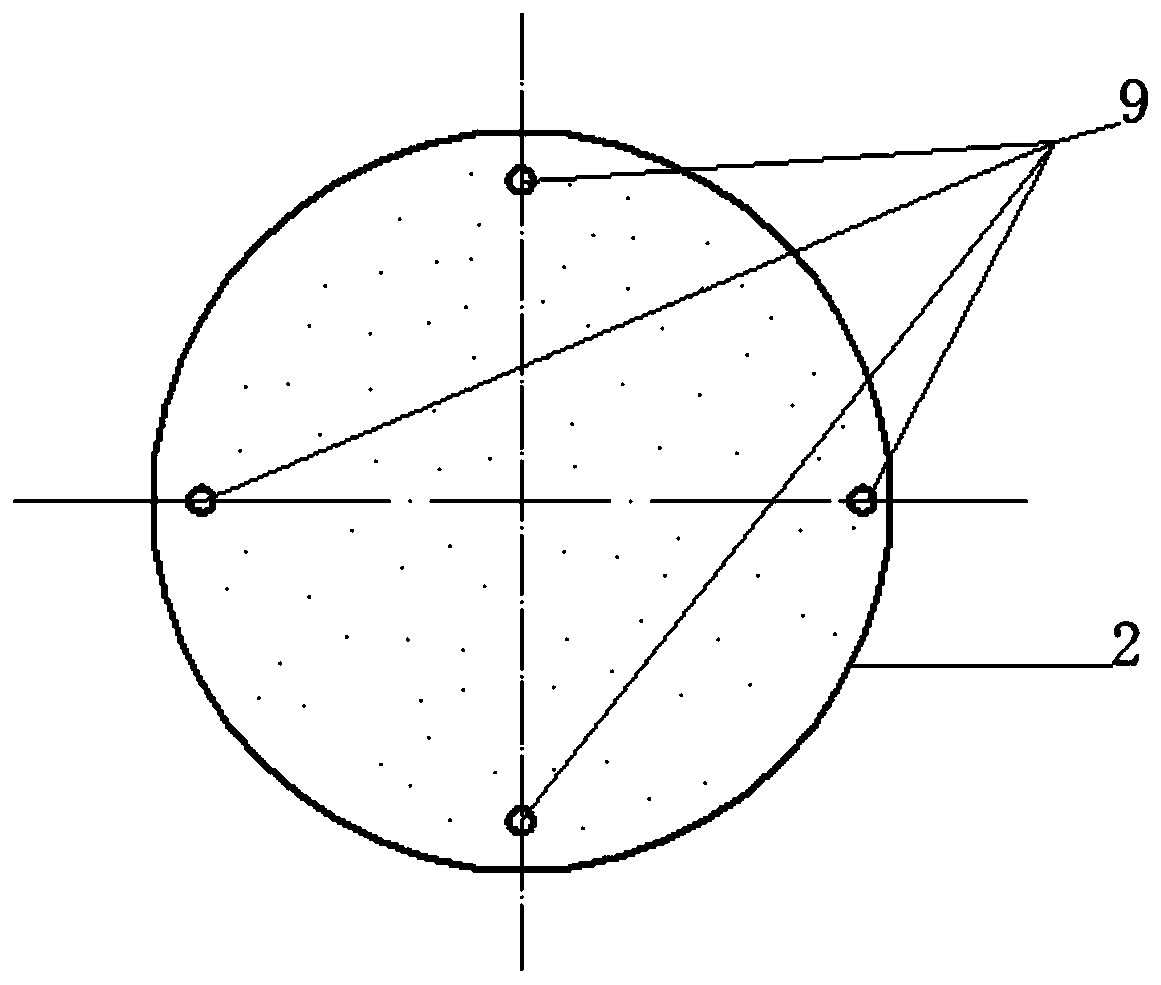

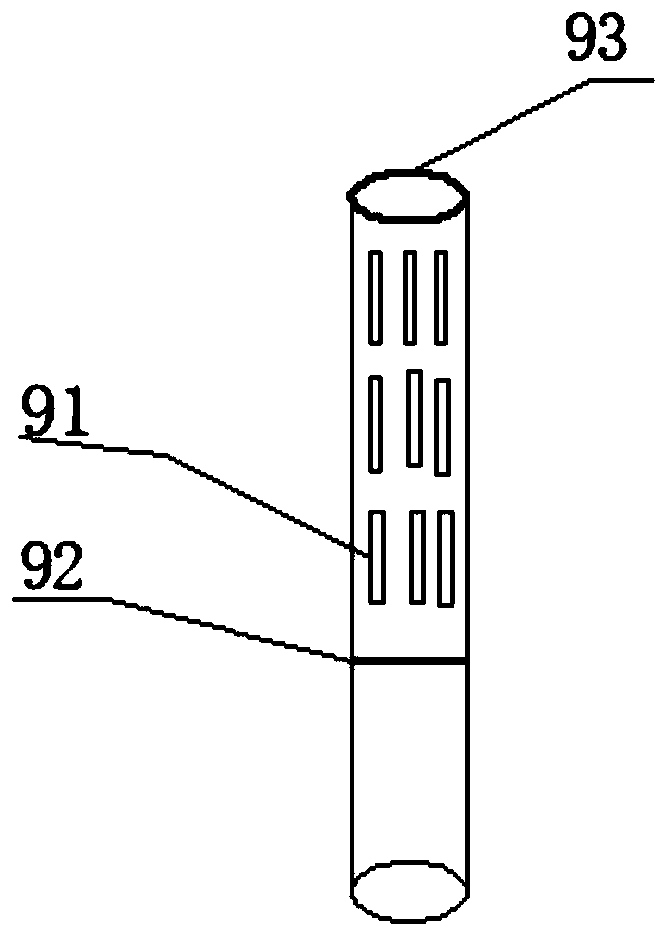

[0058] The static autoclave comprises a static autoclave body 1, a static autoclave cover 3, a sieve plate 2 arranged in the static autoclave body, a balance pipe 9 installed on the sieve plate, a steam inlet, a feeding port, and a vent; The balance pipe 9 includes the upper part of the balance pipe, the welding ring 92 of the upper and lower sieve plates, and the lower part of the balance pipe from top to bottom; the upper end of the balance pipe is sealed, and a number of balance holes 91 are arranged in the middle; preferably, the balance holes 91 is any shape such as a rectangular hole, a circular hole, etc.; preferably, the length ratio between the upper part of the balance tube and the lower part of the balance tube is 2:1; the balance tube 9 is installed on the sieve plate 2 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com