Preparation method and preparation device of SSZ (sulfasalazine)-13 molecular sieve

A preparation device and technology of molecular sieve, which is applied in the field of preparation of SSZ-13 molecular sieve, can solve problems such as prone to abnormality, poor product performance stability, and low production efficiency, and achieve the effect of improving production efficiency and shortening the reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of SSZ-13 molecular sieve

[0035] Proceed as follows:

[0036] 1.1 Add 7.958 kg of water into the glass water bath and add 0.168 kg of aluminum hydroxide, 0.084 g of sodium hydroxide, 2.400 kg of N,N,N-trimethyl-1-amantadine, and 0.060qw of seed crystals at one time while stirring kilogram;

[0037] Among them, the addition of each raw material was stirred for 10 minutes; after adding seed crystals and stirring for 1 hour, 1.952 kg of silica was added;

[0038] After stirring for 1 hour, heat up to 60°C and stir at 60°C for 6 hours to form a jelly; transport the jelly to the buffer storage tank for synthesis;

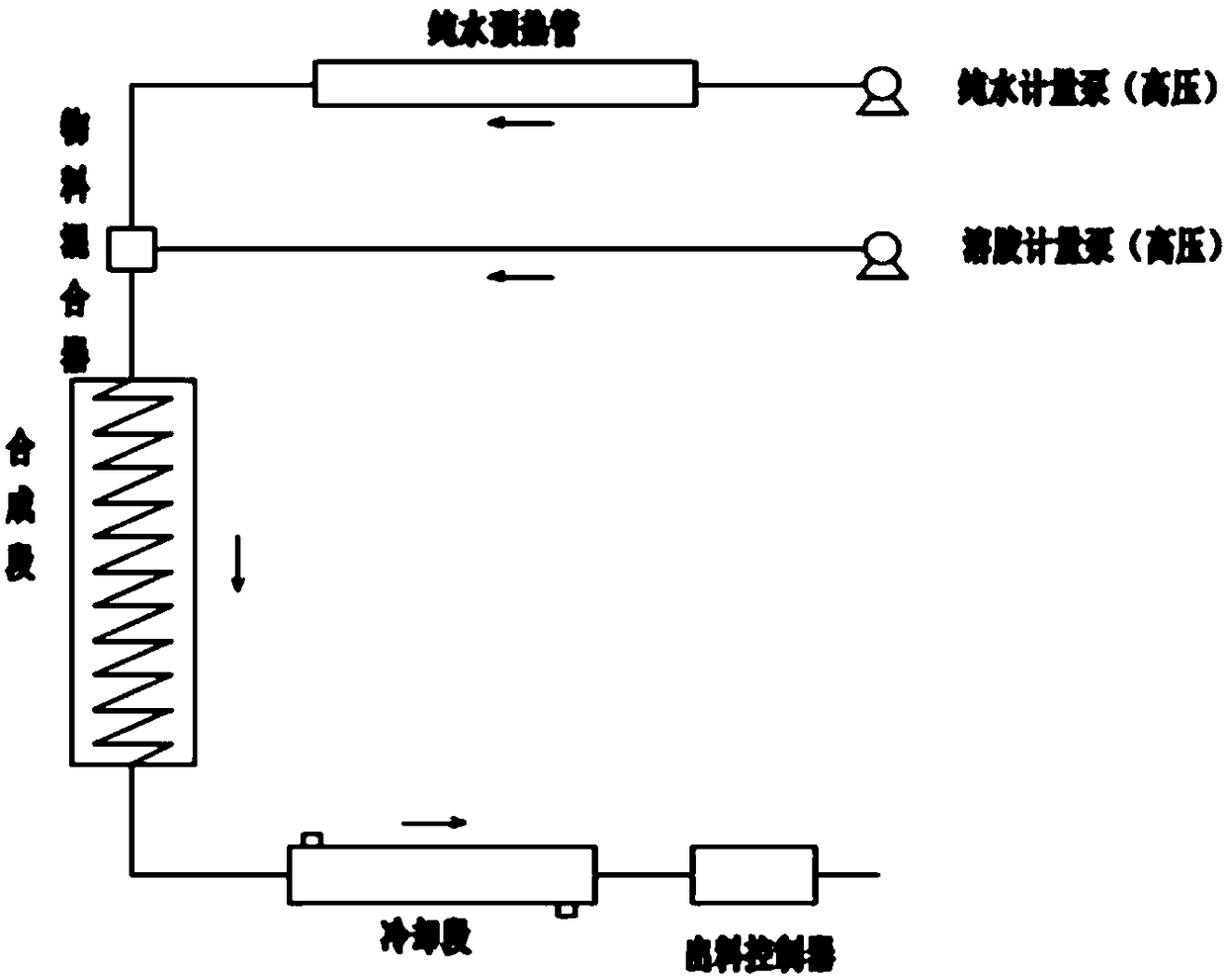

[0039] 1.2 Start the continuous synthesis reactor:

[0040] Set the flow rate of the pure water metering pump to 1000ml / min; set the pure water preheating tube temperature of the tubular super (sub)critical reactor to 270°C; the reaction mixer 290°C, the synthesis section temperature 290°C, and the set outlet temperature 130°C , Test run with pure w...

Embodiment 2

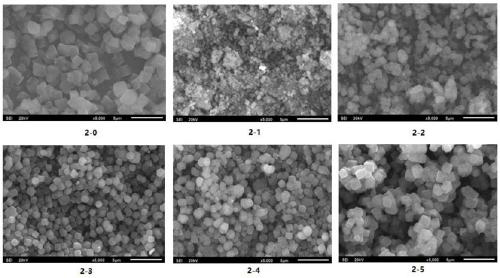

[0045] Example 2 Preparation of a SSZ-13 molecular sieve

[0046] Proceed as follows:

[0047] 2.1 Add 10.974 kg of water to the glass water bath, and under stirring, add 0.736 kg of sodium metaaluminate, 0.147 kg of sodium hydroxide, 5.206 kg of N,N,N-trimethyl-1-amantadine, and 0.152 kg of seed crystals. , The addition of each raw material is stirred for 10 minutes; add seed crystals and stir for 1 hour, then add 5.010 g of silica; stir for 1.5 hours and heat up to 80°C, stir at 80°C for 12 hours to form a jelly; transport the jelly To the buffer storage tank to prepare for synthesis;

[0048] 2.2 Start the continuous synthesis reactor:

[0049] Set the flow rate of the pure water metering pump to 1500ml / min; set the pure water preheating tube temperature of the tubular super (sub)critical reactor to 330°C; the reaction mixer 340°C, the synthesis section temperature 350°C, and the set outlet temperature 130°C , Test run with pure water (instead of the initial mixture), adjust the ...

Embodiment 3

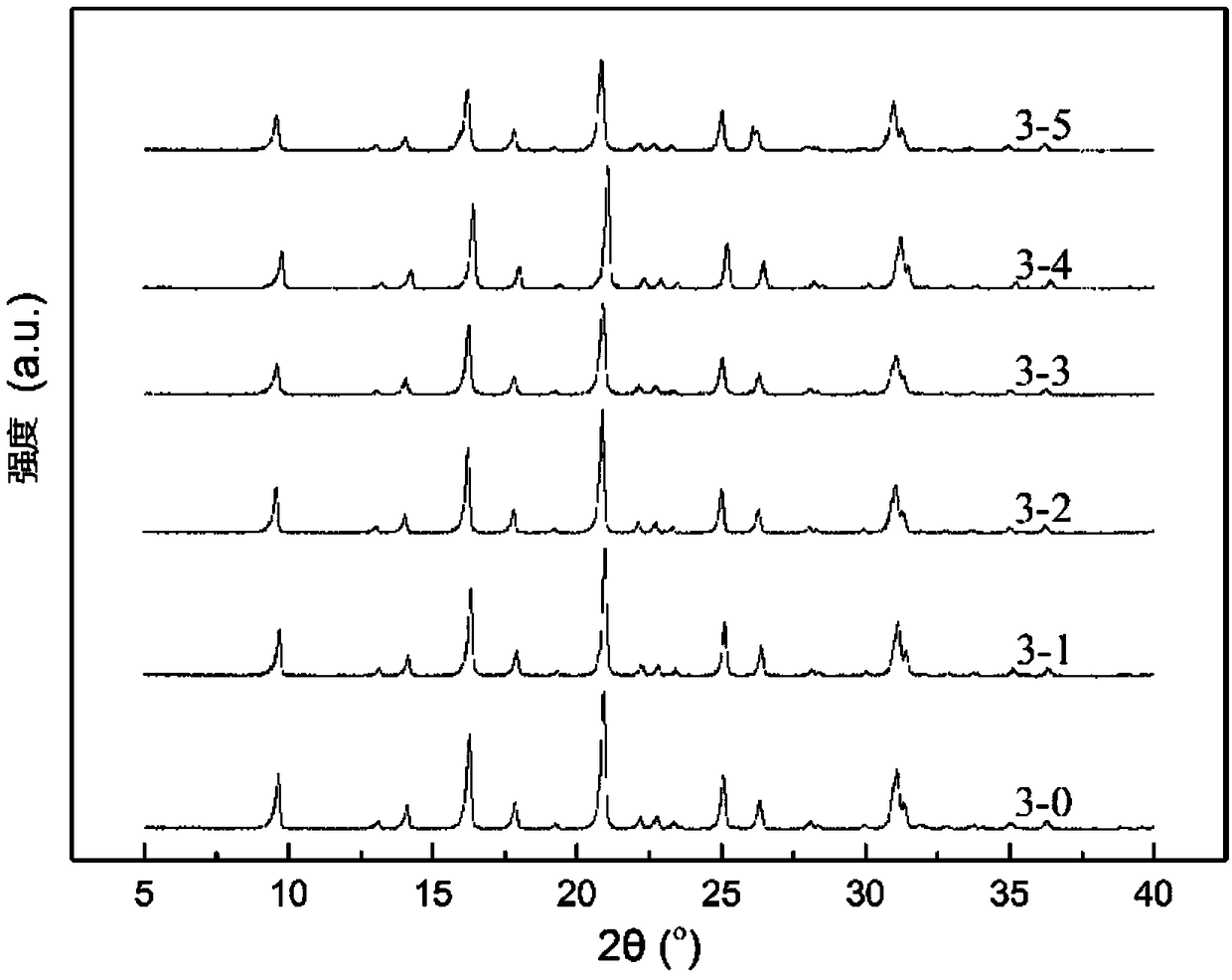

[0054] Example 3 Preparation of a SSZ-13 molecular sieve

[0055] Proceed as follows:

[0056] 3.1 Add 15.85 kg of sodium to a glass water bath kettle, add 3.156 kg of aluminum sulfate, 1.928 kg of sodium hydroxide, 6.506 kg of N,N,N-trimethyl-1-amantadine, 0.200 kg of seed crystals at one time under stirring. Add the raw materials and stir for 10 minutes at intervals; add seed crystals and stir for 2 hours, then add 5.856 kg of silica; stir for 2 hours and heat up to 90℃, stir at 90℃ for 8 hours to form a jelly; transport the jelly to the buffer The storage tank is ready for synthesis;

[0057] 3.2 Start the continuous synthesis reactor:

[0058] Set the flow rate of the pure water metering pump 2000ml / min; set the temperature of the pure water preheating tube of the tubular super (sub)critical reactor to 360°C; the reaction mixer 380°C, the synthesis section temperature 380°C, and the set outlet temperature 130°C , Test run with pure water (instead of the initial mixture), adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com