Production method for high-content mogroside V

A mogroside, production method technology, applied in chemical instruments and methods, glycoside steroids, steroids and other directions, can solve the problems of large water consumption, complex process, low yield and the like, and achieve the effect of improving content and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Pretreatment: put fresh Luo Han Guo in a low-temperature freezer at -25°C, freeze for 1 hour, and immediately heat it with steam at 105°C for 20 seconds;

[0027] 2) Extraction: Peel the pretreated Luo Han Guo, crush the pulp (the seeds remain intact), add water 2.5 times the mass of the pulp to carry out countercurrent circulation extraction, and the extraction temperature is 50°C to obtain the extract;

[0028] 3) Filtration: After the extract is centrifuged by a decanter centrifuge with a separation factor of 3000, the supernatant is filtered through a ceramic membrane with a membrane tube aperture of 50 nm to obtain the filtrate;

[0029] 4) Adsorption and analysis: After the filtrate is absorbed by the DA201-H macroporous resin column, it is pre-washed with 1BV of sodium hydroxide solution with a mass concentration of 2‰, and then pre-washed with 1BV of a hydrochloric acid solution with a mass concentration of 2‰ , then wash with 2BV of pure water until the colu...

Embodiment 2

[0033] 1) Pretreatment: put fresh Luo Han Guo in a low-temperature freezer at -10°C, freeze for 1.5 hours, and immediately heat it with steam at 120°C for 30 seconds;

[0034] 2) Extraction: Peel the pretreated Luo Han Guo, break the pulp (the seeds remain intact), add water 6 times the mass of the pulp to carry out countercurrent circulation extraction, and the extraction temperature is 90°C to obtain the extract;

[0035] 3) Filtration: the extract is centrifuged by a decanter centrifuge with a separation factor of 3500, and then centrifuged by a disc centrifuge with a separation factor of 8500. The supernatant is filtered through a ceramic membrane with a membrane tube pore size of 200 nm to obtain the filtrate;

[0036] 4) Adsorption and analysis: After the filtrate is adsorbed by T-28 macroporous resin column, it is pre-washed with 3BV of sodium hydroxide solution with a mass concentration of 6‰, and then pre-washed with 3BV of hydrochloric acid solution with a mass concen...

Embodiment 3~4

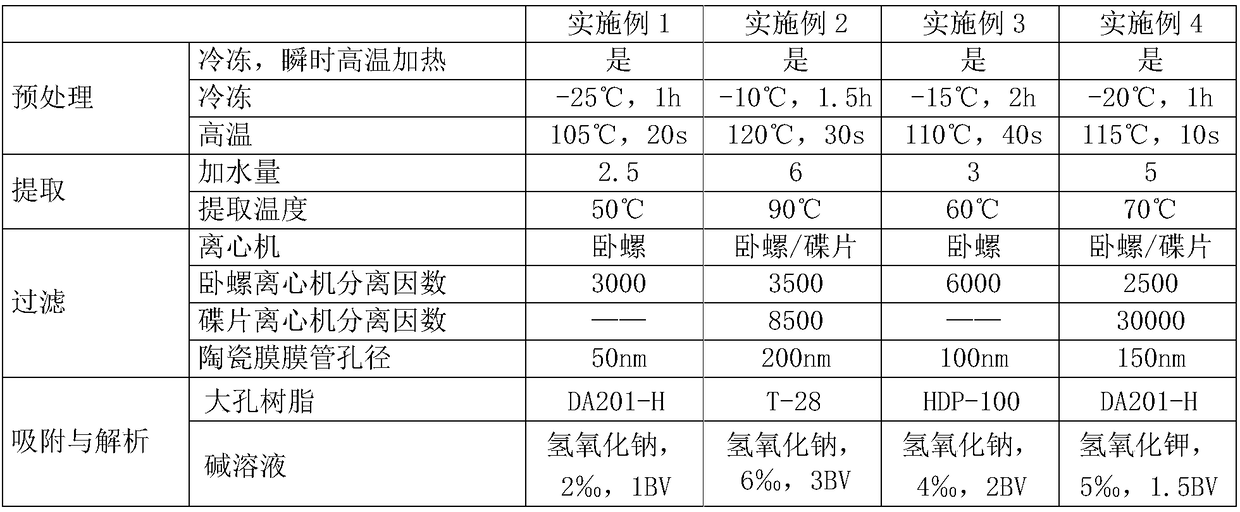

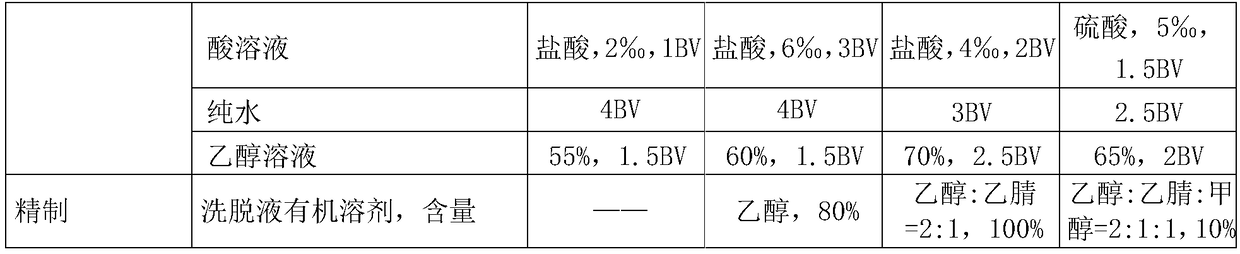

[0041] The preparation method of Examples 3-4 is similar to that of Example 2, the only difference being that the specific process parameters are different (see the table below for details, wherein the "amount of water added" is the multiple of the mass of the raw material Luo Han Guo pulp).

[0042]

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com