Production method of slow release polycarboxylate water reducer

A technology of slow-release polycarboxylate and its manufacturing method, which is applied in the field of preparation of slow-release polycarboxylate water reducer, which can solve problems such as unfavorable construction, high viscosity, and great difference in concrete slump retention, and achieve good compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

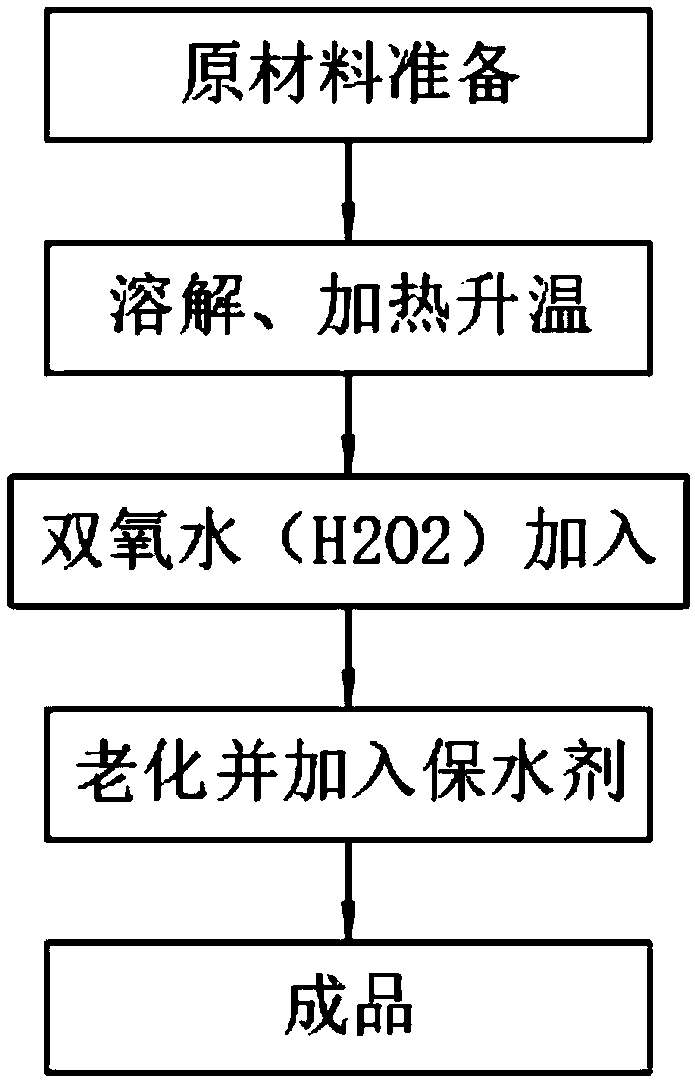

[0023] A kind of manufacture method of slow-release polycarboxylate superplasticizer, comprises the steps:

[0024] Step 1: Preparation of raw materials: isopentenol polyoxyethylene ether (TPEG), hydrogen peroxide (H 2 o 2 ), acrylic acid (AA), hydroxyethyl acrylate, vinyl acetate, vitamin C, chain transfer agent, water retention agent, liquid caustic soda (NaOH), deionized water; Based on the characteristics of slow hydrolysis under alkaline conditions, it has the effect of slow release and slump protection;

[0025] Step 2: Dissolving and heating up: add deionized water and prenol polyoxyethylene ether (TPEG) to the biscuits equipped with a stirrer and a thermometer, stir to dissolve, and heat up to 52°C;

[0026] Step three: Hydrogen peroxide (H 2 o 2 ) adding: after the mixed solution is heated in the beaker of step 2, add hydrogen peroxide (H 2 o 2 );

[0027] Step 4: aging and adding water retaining agent: hydrogen peroxide (H 2 o 2 ) after the addition of acryl...

Embodiment 2

[0031] A kind of manufacture method of slow-release polycarboxylate superplasticizer, comprises the steps:

[0032] Step 1: Preparation of raw materials: isopentenol polyoxyethylene ether (TPEG), hydrogen peroxide (H 2 o 2 ), acrylic acid (AA), hydroxyethyl acrylate, vinyl acetate, vitamin C, chain transfer agent, water retention agent, liquid caustic soda (NaOH), deionized water; Based on the characteristics of slow hydrolysis under alkaline conditions, it has the effect of slow release and slump protection;

[0033] Step 2: Dissolving and heating up: Add deionized water and prenol polyoxyethylene ether (TPEG) to the biscuits equipped with a stirrer and a thermometer, stir to dissolve, and heat up to 55°C;

[0034] Step three: Hydrogen peroxide (H 2 o 2 ) adding: after the mixed solution is heated in the beaker of step 2, add hydrogen peroxide (H 2 o 2 );

[0035] Step 4: aging and adding water retaining agent: hydrogen peroxide (H 2 o 2 ) after the addition of acryl...

Embodiment 3

[0039] A kind of manufacture method of slow-release polycarboxylate superplasticizer, comprises the steps:

[0040] Step 1: Preparation of raw materials: isopentenol polyoxyethylene ether (TPEG), hydrogen peroxide (H 2 o 2 ), acrylic acid (AA), hydroxyethyl acrylate, vinyl acetate, vitamin C, chain transfer agent, water retention agent, liquid caustic soda (NaOH), deionized water; Based on the characteristics of slow hydrolysis under alkaline conditions, it has the effect of slow release and slump protection;

[0041] Step 2: Dissolving and heating up: add deionized water and prenol polyoxyethylene ether (TPEG) to the biscuits equipped with a stirrer and a thermometer, stir to dissolve, and heat up to 58°C;

[0042] Step three: Hydrogen peroxide (H 2 o 2 ) adding: after the mixed solution is heated in the beaker of step 2, add hydrogen peroxide (H 2 o 2 );

[0043] Step 4: aging and adding water retaining agent: hydrogen peroxide (H 2 o 2 ) after the addition of acryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com