Environment-friendly plastic with high weather resistance and preparation method thereof

An environmentally friendly plastic and weather resistance technology, which is applied in the field of plastic preparation, can solve the problems of poor environmental protection effect, long-lasting environmental protection effect, complicated preparation method, etc., achieves the suppression of discoloration and brittleness, obvious toughening effect, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

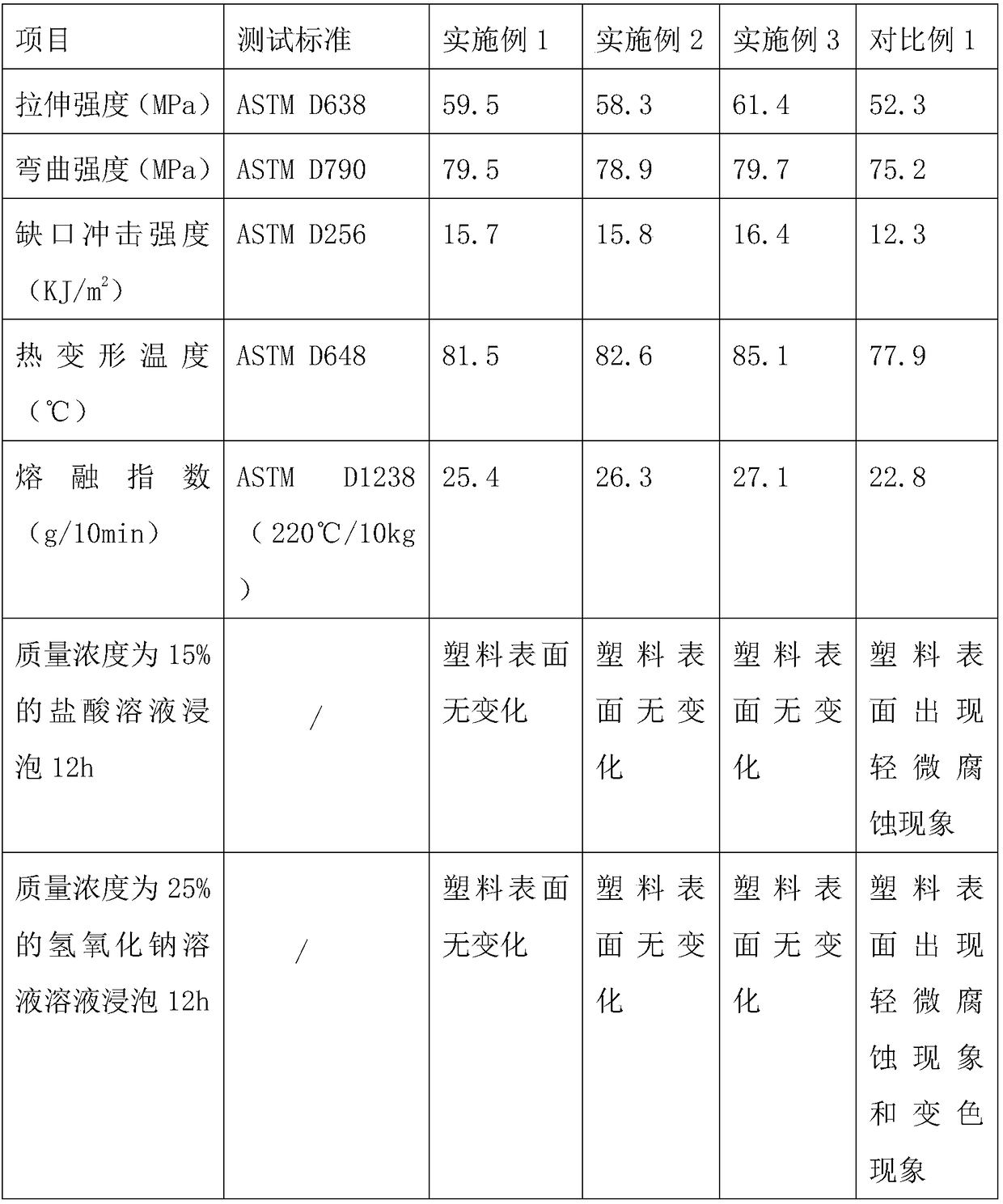

Examples

Embodiment 1

[0029] An environmentally friendly plastic with high weather resistance, including the following raw materials in parts by weight: 23 parts of plant straw, 15 parts of fruit shell, 8 parts of polypropylene, 18 parts of charcoal ash, 6 parts of toughening agent, 7 parts of organic solvent, modified carbonic acid 8 parts of calcium, 9 parts of talcum powder, 5 parts of silicone solution, 12 parts of polymethyl methacrylate, 5 parts of curing agent, 2 parts of antibacterial agent, 3 parts of antioxidant, 3 parts of coupling agent and 4 parts of defoamer share.

[0030] A method for preparing environmentally friendly plastics with high weather resistance, comprising the following preparation steps:

[0031] a. Grind plant stalks and fruit shells into powder, then dry them at 52°C for 0.6h, mix them with polypropylene, charcoal ash, and toughening agent and put them into the internal mixer, heat and stir at 90°C for 1.2 h, to obtain mixture one;

[0032] b. Mix mixture 1, modifie...

Embodiment 2

[0042] An environmentally friendly plastic with high weather resistance, including the following raw materials in parts by weight: 23 parts of plant straw, 15 parts of fruit shell, 10 parts of polypropylene, 14 parts of charcoal ash, 5 parts of toughening agent, 5 parts of organic solvent, modified carbonic acid 8 parts of calcium, 9 parts of talcum powder, 7 parts of silicone solution, 16 parts of polymethyl methacrylate, 3 parts of curing agent, 4 parts of antibacterial agent, 4 parts of antioxidant, 3 parts of coupling agent and 4 parts of defoamer share.

[0043] A method for preparing environmentally friendly plastics with high weather resistance, comprising the following preparation steps:

[0044] a. Grind plant stalks and fruit shells into powder, then dry them at 50°C for 0.5h, mix them with polypropylene, charcoal ash, and toughening agent and put them into the internal mixer, heat and stir at 86°C for 1.2 h, to obtain mixture one;

[0045] b. Mix mixture 1, modifi...

Embodiment 3

[0055] An environmentally friendly plastic with high weather resistance, including the following raw materials in parts by weight: 21 parts of plant straw, 18 parts of fruit shell, 11 parts of polypropylene, 15 parts of charcoal ash, 4 parts of toughening agent, 6 parts of organic solvent, modified carbonic acid 9 parts of calcium, 8 parts of talcum powder, 6 parts of silicone solution, 15 parts of polymethyl methacrylate, 3 parts of curing agent, 4 parts of antibacterial agent, 3 parts of antioxidant, 5 parts of coupling agent and 4 parts of defoaming agent share.

[0056] A method for preparing environmentally friendly plastics with high weather resistance, comprising the following preparation steps:

[0057] a. Grind plant stalks and fruit shells into powder, dry at 50°C for 0.6h, mix with polypropylene, charcoal ash, and toughening agent, put them into the internal mixer, heat and stir at 90°C for 1.2 h, to obtain mixture one;

[0058] b. Mix mixture 1, modified calcium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com