Zinc impregnation agent used for preparing heat diffusion zinc impregnation layer on surface of oil casing pipe screwed joint, and zinc impregnation method thereof

A technology of threaded joints and oil-casing pipes, applied in the direction of solid-state diffusion coating, coating, metal material coating technology, etc., can solve environmental pollution and other problems, achieve excellent wear resistance, fast penetration speed, and shorten production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

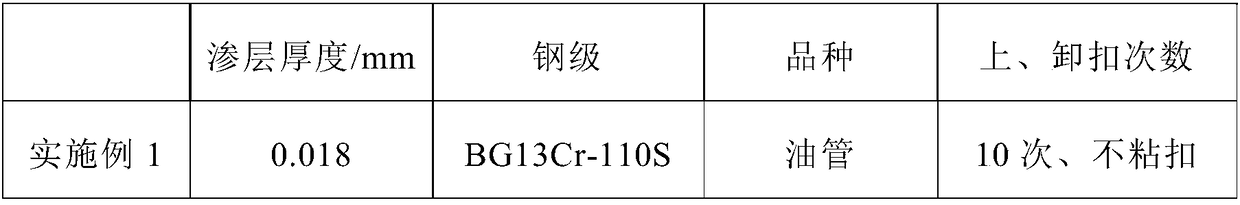

Embodiment 1

[0065] Penetration agent composition: 40% Zn powder, 2% Cu powder, 0.5% Ni powder, 3% La 2 o 3 , 1% NH 4 Cl, balance Al 2 o 3 . Zinc shedding temperature 400 ℃, holding time 0.75h.

Embodiment 2

[0067] Penetration agent composition: 50% Zn powder, 1.5% Cu powder, 1% Ni powder, 2% La 2 o 3 , 1.5% NH 4 Cl, balance Al 2 o 3 . Zinc shedding temperature 380 ℃, holding time 1.0h.

Embodiment 3

[0069] Penetration agent composition: 60% Zn powder, 0.5% Cu powder, 1% Ni powder, 1% La 2 o 3 , 2% NH 4 Cl, balance Al 2 o 3 . Zinc shedding temperature 400 ℃, holding time 1.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com