Protection system of turbine compressor

A technology of turbine compressor and protection system, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of unit wear, affecting the working environment, compressor surge, etc., and achieves simple structure and prevents wear , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

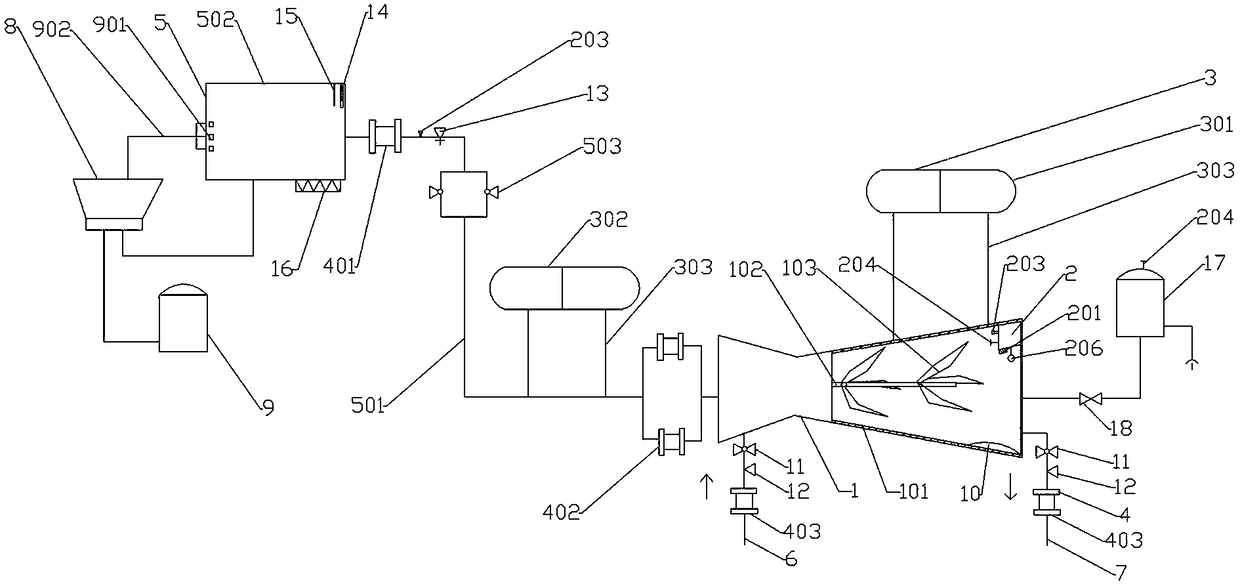

[0035] Such as figure 1 Shown: the protection system of the turbocompressor, including a turbocompressor body 1, the turbocompressor body 1 includes an oil tank 502 connected with an oil outlet pipe 501 and a casing 101, and the casing 101 is provided with a main shaft 102 and an impeller 103 , the impeller 103 is arranged on the main shaft 102; the protection system also includes a monitoring device 2, a cooling device 3, a filtering device 4 and a lubricating device 5, and the monitoring device 2, the cooling device 3, the filtering device 4 and the lubricating device 5 are all connected with the turbine Compressor body 1 connection;

[0036] The monitoring device 2 includes a temperature detector 201, a flow meter 203, a pressure gauge 204 and an axial displacement protection mechanism 206 arranged in the cylinder, and the axial displacement protection mechanism 206 includes an electromagnetic axial displacement transmitter, for example: BSQ031B axial displacement transmit...

Embodiment 2

[0043] On the basis of embodiment 1, further,

[0044] A muffler 10 is arranged inside the turbocompressor body 1 .

[0045] The air inlet of the turbine compressor body 1 is provided with an air intake pipe 6, and the air outlet of the turbine compressor body 1 is provided with an air outlet pipe 7. Both the air inlet pipe 6 and the air outlet pipe 7 are provided with a check valve 11 and a vent valve. valve 12.

Embodiment 3

[0047] On the basis of embodiment 2, further,

[0048] The cooler is a plate cooler.

[0049] The cooler includes an air cooler and a water cooler, the cooling medium in the air cooler is inert gas, and the cooling medium in the water cooler is deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com