LED chip with annular electrode structure and method for preparing LED chip

A technology of LED chips and ring electrodes, applied in the field of optoelectronics, can solve the problem of limited improvement in brightness, and achieve the effects of improving brightness, reducing etching area, and making wire bonding easier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

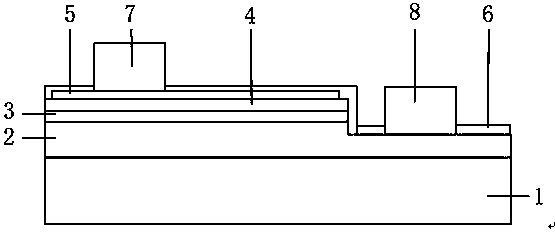

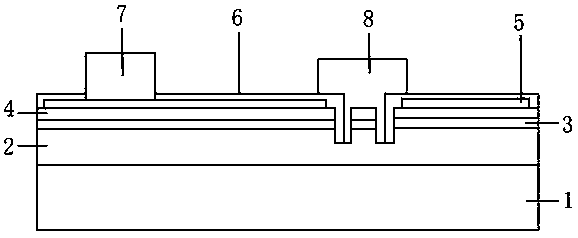

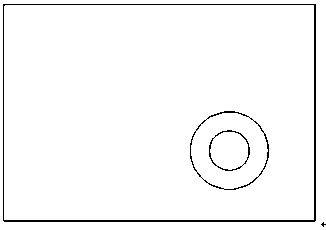

[0026] different from figure 1 The conventional LED chip shown, the LED chip with ring electrode structure of the present invention, as figure 2 As shown, it includes a substrate 1 , an n-type GaN layer 2 , a quantum well layer 3 and a p-type GaN layer 4 sequentially arranged from bottom to top. An annular mesa is arranged on the n-type GaN layer 2 , a transparent conductive layer 5 is arranged on the p-type GaN layer 4 , and a passivation layer 6 is arranged on the transparent conductive layer 5 . A p-electrode 7 is arranged on the transparent conductive layer 5, and an n-electrode 8 is arranged on the ring-shaped mesa, and the n-electrode 8 is ring-shaped.

[0027] The substrate 1 may be a sapphire substrate, a SiC substrate or a silicon substrate. The transparent conductive layer 5 is ITO (indium tin oxide), ZnO or graphene. Passivation layer 6 is SiO 2 or SiN. The p-electrodes 7 and n-electrodes 8 are composed of two or more metal film systems of Cr, Ti, Pd, Pt, Al, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com