A dual-wavelength semiconductor laser chip structure

A chip structure and semiconductor technology, applied in the direction of semiconductor laser device, laser device, active region structure, etc., can solve the problems of complex process, increase product cost, no cost advantage, etc., achieve simple manufacturing process and reduce manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

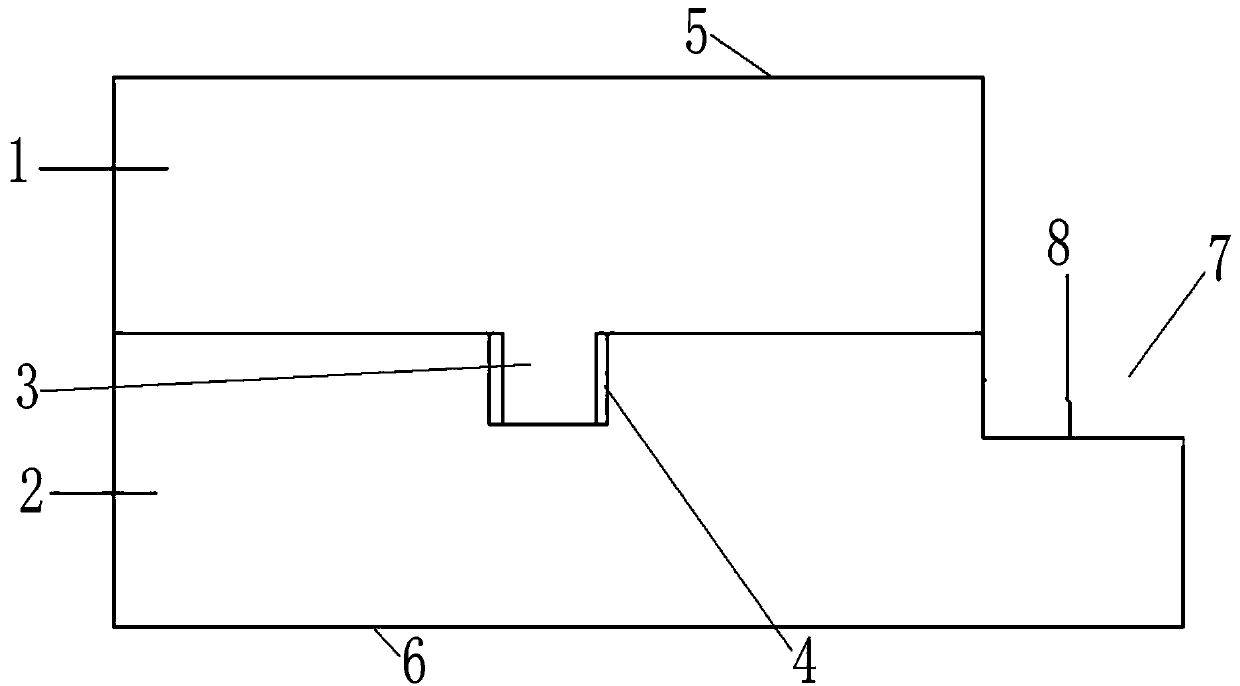

[0024] Further, it also includes a notch-shaped deep groove 7 arranged on the outer end of the epitaxial wafer II 2, the upper end surface of the epitaxial wafer I 1 is provided with a negative electrode I 5 conducting with the strip-shaped light emitting region 3, and the lower end surface of the epitaxial wafer II 2 is provided with There is a negative electrode II 6 connected to the groove-shaped light emitting region 4, and a positive electrode 8 connected to the strip-shaped light emitting region 3 and the groove-shaped light emitting region 4 is arranged on the upper end surface of the deep groove 7. By setting the deep groove 7 on the epitaxial wafer II 2, the strip-shaped light-emitting area 3 and the groove-shaped light-emitting area 4 can share a positive electrode 8, thereby further optimizing the structure and reducing the manufacturing cost.

Embodiment 2

[0026] Preferably, the width of the bar-shaped light-emitting region 3 of the dual-wavelength semiconductor laser chip structure is 4 . The width of the slot-shaped light-emitting area 4 is 8 .

Embodiment 3

[0028] Preferably, the width of the deep groove 7 of the dual-wavelength semiconductor laser chip structure is 200 , whose depth is 10-30 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com