Polyurethane foam air purification and filtration material and preparation method

A polyurethane foam and air purification technology, applied in the field of air purification, can solve the problems of unsatisfactory purification effect, complex preparation process, limited adsorption capacity, etc., and achieve the effects of excellent air purification effect, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

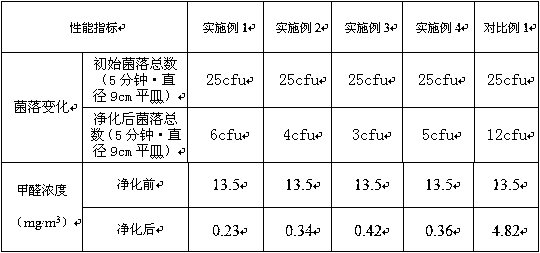

Examples

Embodiment 1

[0029] (1) Disperse 5 parts by weight of silver nitrate, 30 parts by weight of activated carbon, and 70 parts by weight of water evenly, and soak for 12 hours, then add 1 part by weight of hydrazine hydrate, heat to 80°C for 1 hour, then wash and dry to obtain activated carbon of precious metals;

[0030] (2) Immerse the activated carbon powder loaded with precious metals into sodium chloride solution, 25 parts by weight of activated carbon powder loaded with precious metals, 10 parts by weight of sodium chloride, 40 parts by weight of water, soak for 6 hours, so that sodium chloride can fully infiltrate the active The micropores of carbon are then dried, so that sodium chloride occupies the micropores of activated carbon and falls on the precious metal interface;

[0031] (3) 30 parts by weight of activated carbon loaded with precious metals and sodium chloride obtained in step (2), 4 parts by weight of foaming agent ammonium bicarbonate, 3 parts by weight of chain-extending ...

Embodiment 2

[0033] (1) Disperse 5 parts by weight of silver nitrate, 30 parts by weight of activated carbon, and 70 parts by weight of water evenly, soak for 15 hours, then add 2 parts by weight of hydrazine hydrate, heat to 600°C for 2 hours, then wash and dry to obtain activated carbon of precious metals;

[0034] (2) Immerse the activated carbon powder loaded with precious metals into sodium chloride solution, 25 parts by weight of activated carbon powder loaded with precious metals, 25 parts by weight of sodium chloride, 100 parts by weight of water, and soak for 10 hours to fully infiltrate the active carbon powder with sodium chloride. The micropores of carbon are then dried, so that sodium chloride occupies the micropores of activated carbon and falls on the precious metal interface;

[0035] (3) 10 parts by weight of activated carbon loaded with precious metals and sodium chloride obtained in step (2), 2 parts by weight of foaming agent sodium bicarbonate, 3 parts by weight of cha...

Embodiment 3

[0037] (1) Disperse 3 parts by weight of silver nitrate, 30 parts by weight of activated carbon, and 70 parts by weight of water evenly, soak for 15 hours, then add 3 parts by weight of hydrazine hydrate, heat to 80°C for 4 hours, then wash and dry to obtain activated carbon of precious metals;

[0038] (2) Immerse the activated carbon powder loaded with precious metals into sodium chloride solution, 45 parts by weight of activated carbon powder loaded with precious metals, 25 parts by weight of sodium chloride, 100 parts by weight of water, and soak for 10 hours to fully infiltrate the active carbon powder with sodium chloride. The micropores of carbon are then dried, so that sodium chloride occupies the micropores of activated carbon and falls on the precious metal interface;

[0039](3) 20 parts by weight of activated carbon loaded with precious metals and sodium chloride obtained in step (2), 4 parts by weight of foaming agent ammonium bicarbonate, 5 parts by weight of cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com