Device for composite adsorption microwave recovery or pyrolysis treatment of organic waste gas

A compound adsorption and organic waste gas technology, which is applied in gas treatment, filtration treatment, water/sewage treatment, etc., can solve the problems of increasing air flow resistance, unsatisfactory practical application, and the filter belt is easy to be blocked by pollution, so as to achieve the utilization of resources and energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

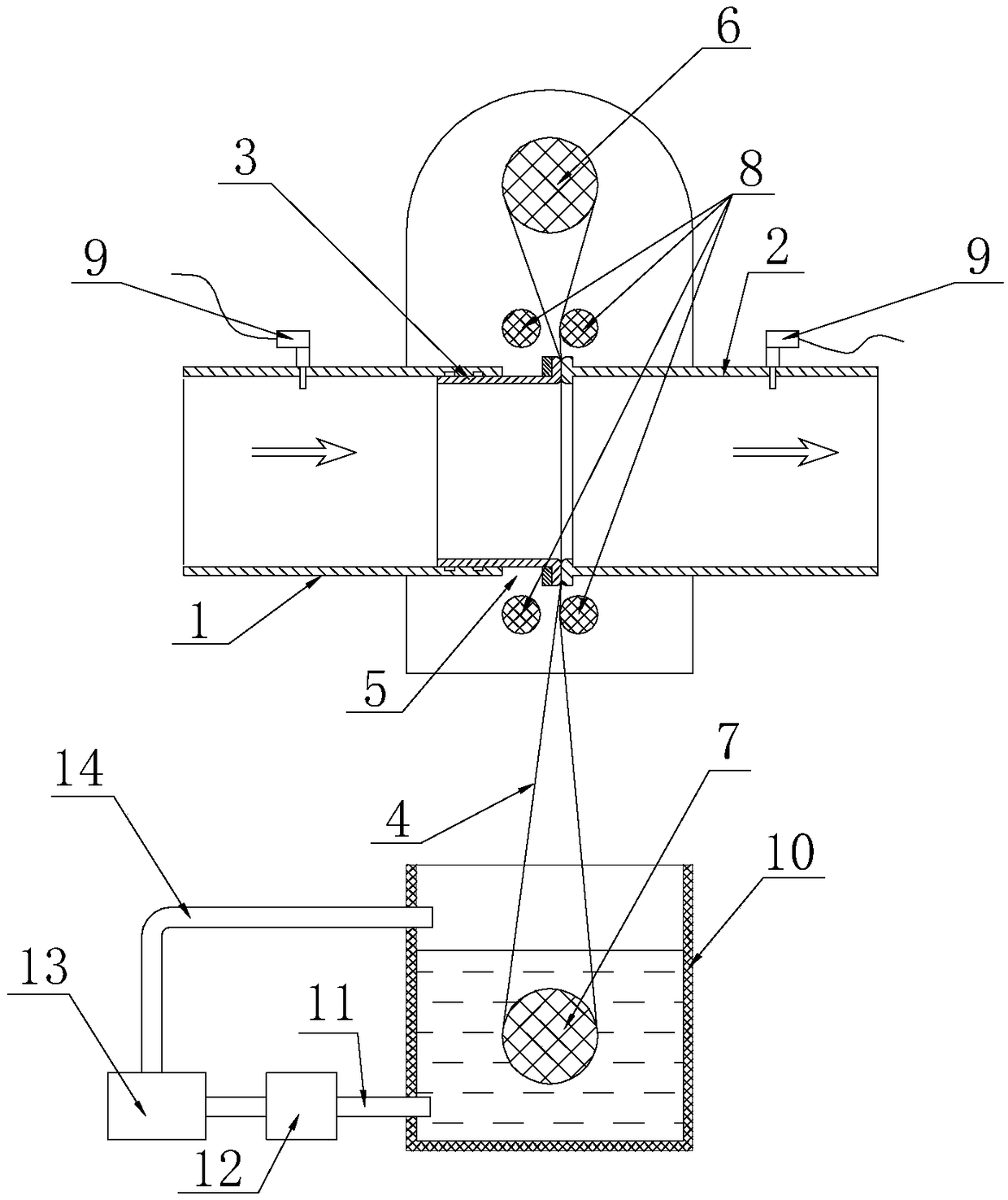

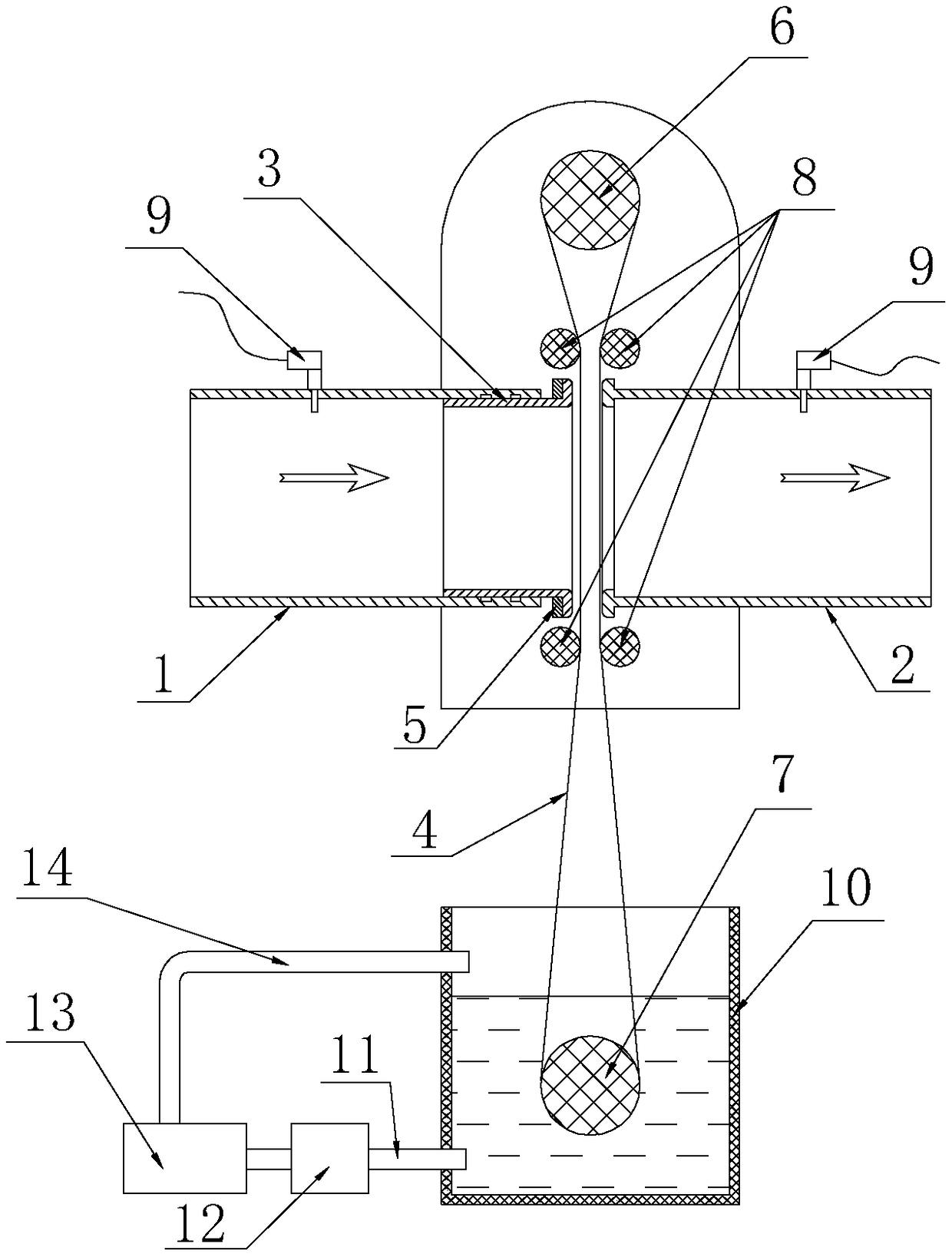

[0092] A device for compound adsorption microwave recovery or pyrolysis treatment of organic waste gas, including a pretreatment unit and a plurality of parallel microwave treatment units.

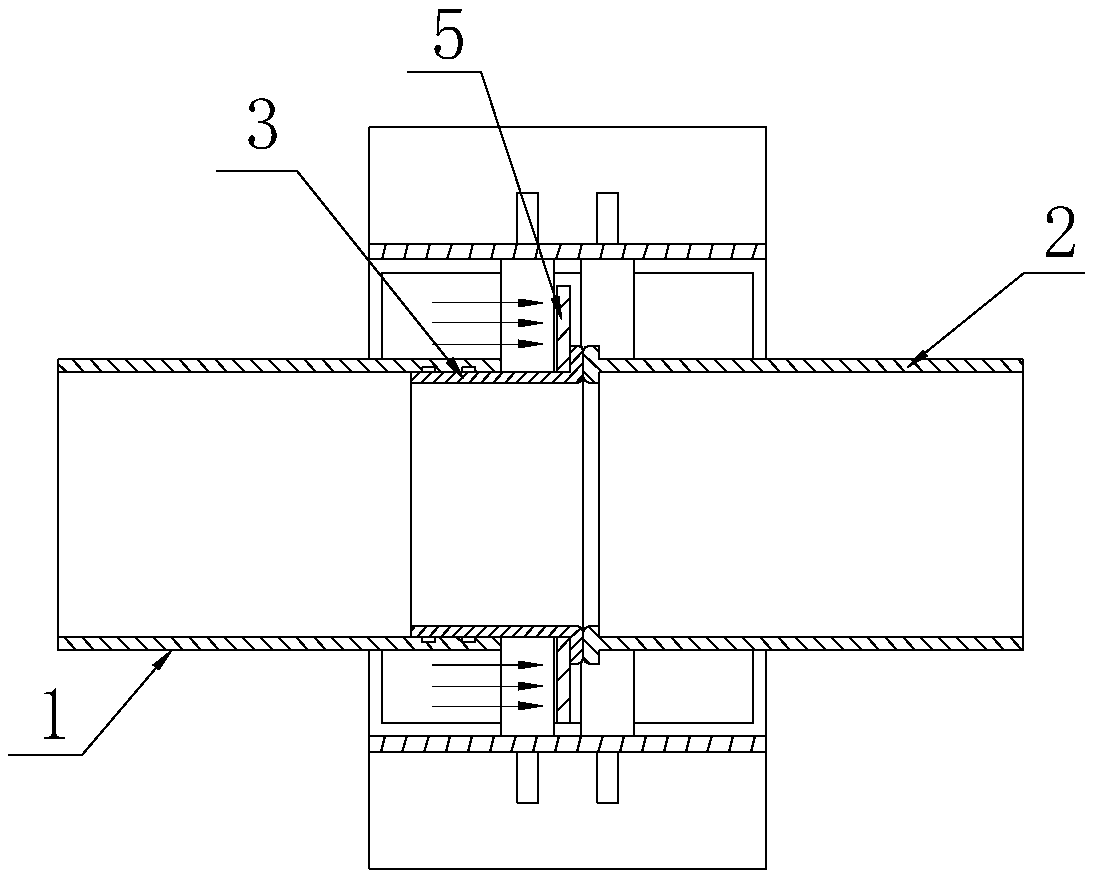

[0093] Such as Figure 1-4 As shown, the pretreatment unit includes a feed pipe 1, a discharge pipe 2, a movable pipe 3, a filter belt 4 (glass fiber filter belt), a circulation transmission mechanism, and a cleaning mechanism; the outlet end of the feed pipe and the discharge pipe The inlet end is opposite to each other, and the movable pipe is arranged between the feed pipe and the discharge pipe.

[0094] The inlet end of the movable pipe is movably socketed with the outlet end of the feed pipe and the outlet end of the movable pipe is opposite to the inlet end of the discharge pipe. The edge of the outlet end of the movable pipe is provided with a pressing plate 5, and the movable pipe is driven by a supporting The mechanism (air cylinder) exerts an external force on the pressure plat...

Embodiment 2

[0113] The difference between this embodiment and Embodiment 1 is that the inlet end of the movable pipe is opposite to the outlet end of the feed pipe and the outlet end of the movable pipe is movably socketed with the inlet end of the discharge pipe; the filter belt is arranged vertically on Circular delivery can be realized between the feed pipe and the active pipe and through the circulation transmission mechanism.

Embodiment 3

[0115] This embodiment adopts the preprocessing unit of scheme two: as Figure 8-10 As shown, it includes a box body 1000, a rolling filter cartridge 1010 and a driving mechanism.

[0116] The box body is provided with an air inlet 1020 and an air outlet 1030; the rolling filter cartridge is provided with a filter cartridge support 1140. The rolling filter cartridge is horizontally arranged in the box body and its two ends are rotatably connected with the box body through bearings 1090 . The rotating surface of the rolling filter cartridge is the filtering surface (stainless steel mesh screen), and one of the end faces of the rolling filter cartridge is provided with an opening to seal and communicate with the air outlet (the opening and the air outlet are provided with a sealing ring 1130 (EVA sealing ring and O-shaped seal) lock up).

[0117] Described driving mechanism comprises motor 1100, motor pulley 1110, rolling pulley 1120 and belt; Described motor pulley is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com